Quality Assurance

Attractive Plastics is committed to continuous improvement and optimization of custom injection molding

manufacturing capabilities from prototype to production, as well as corresponding quality control

processes, including mold design, CNC machining, mold manufacturing, injection molding, and more.

We strictly follow the ISO 9001 certified quality management system, based on a series of standardized

production processes and work instructions, and rely on advanced testing equipment to measure, inspect

and record each production step to ensure compliance with customer specifications.

-

ISO 9001:2015 certified, ROHS, REACH

-

IATF 16949:2016

-

Quality Report Every Order

-

Tolerances down to ±0.0004″ (0.01mm)

How Attractive Plastics Guarantees Superior Quality

- Quality Raw Materials

- Precision Molding

- Reliable Mold

- Experienced Project Engineers

- Rigorous Inspection

Quality Raw Materials

Materials are the basis of making products, and we attach great importance to the quality of

materials. Every batch of material that arrives is subjected to rigorous testing. And make

relevant

records for inquiry.

More Details>>

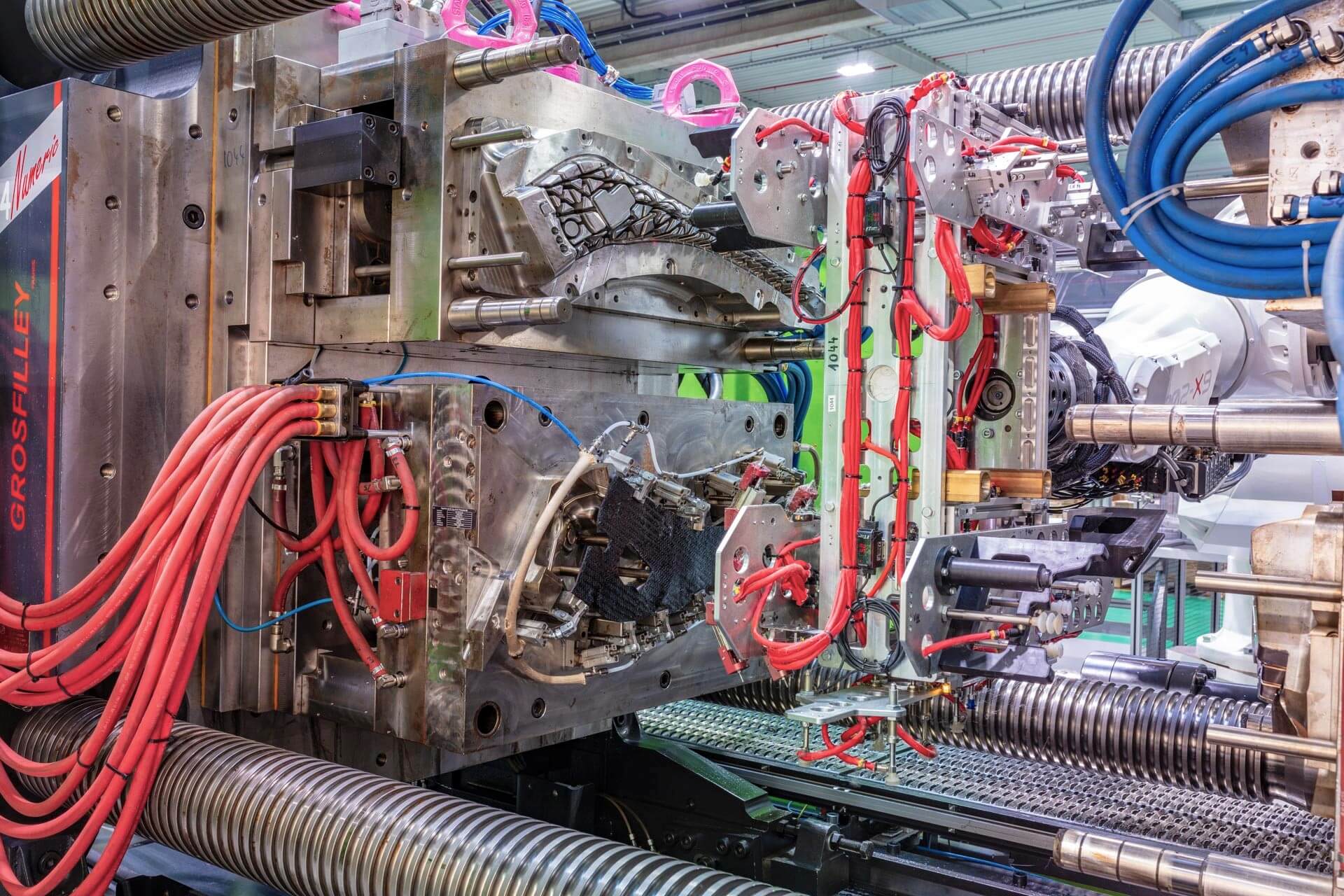

Precision Molding

Relying on precision molds and advanced injection molding machines, coupled with our

professional

process engineers, this is enough for us to easily complete a high demand tight tolerance

plastic

parts.

More Details>>

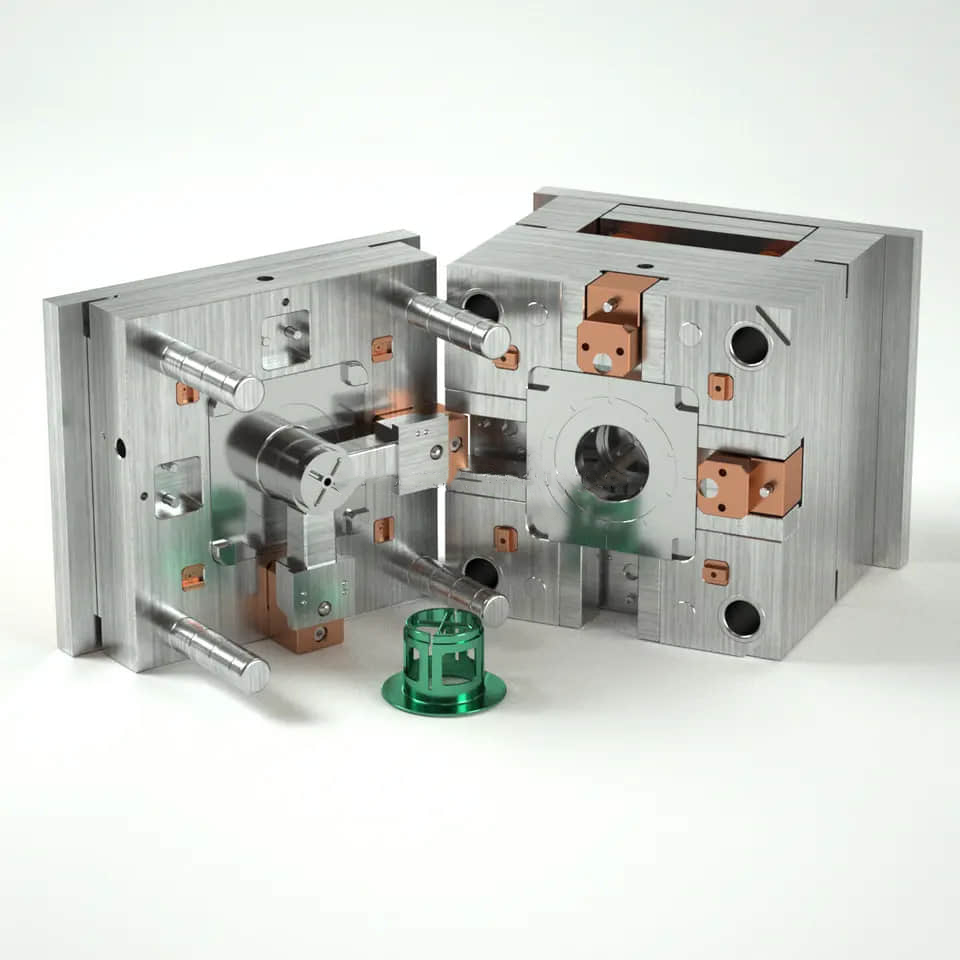

Reliable Mold

Excellent products start with precision and high reliability molds, but the key to making

excellent

molds is innovative mold design, tight tolerance machining, as well as good surface finished

etc.

More Details>>

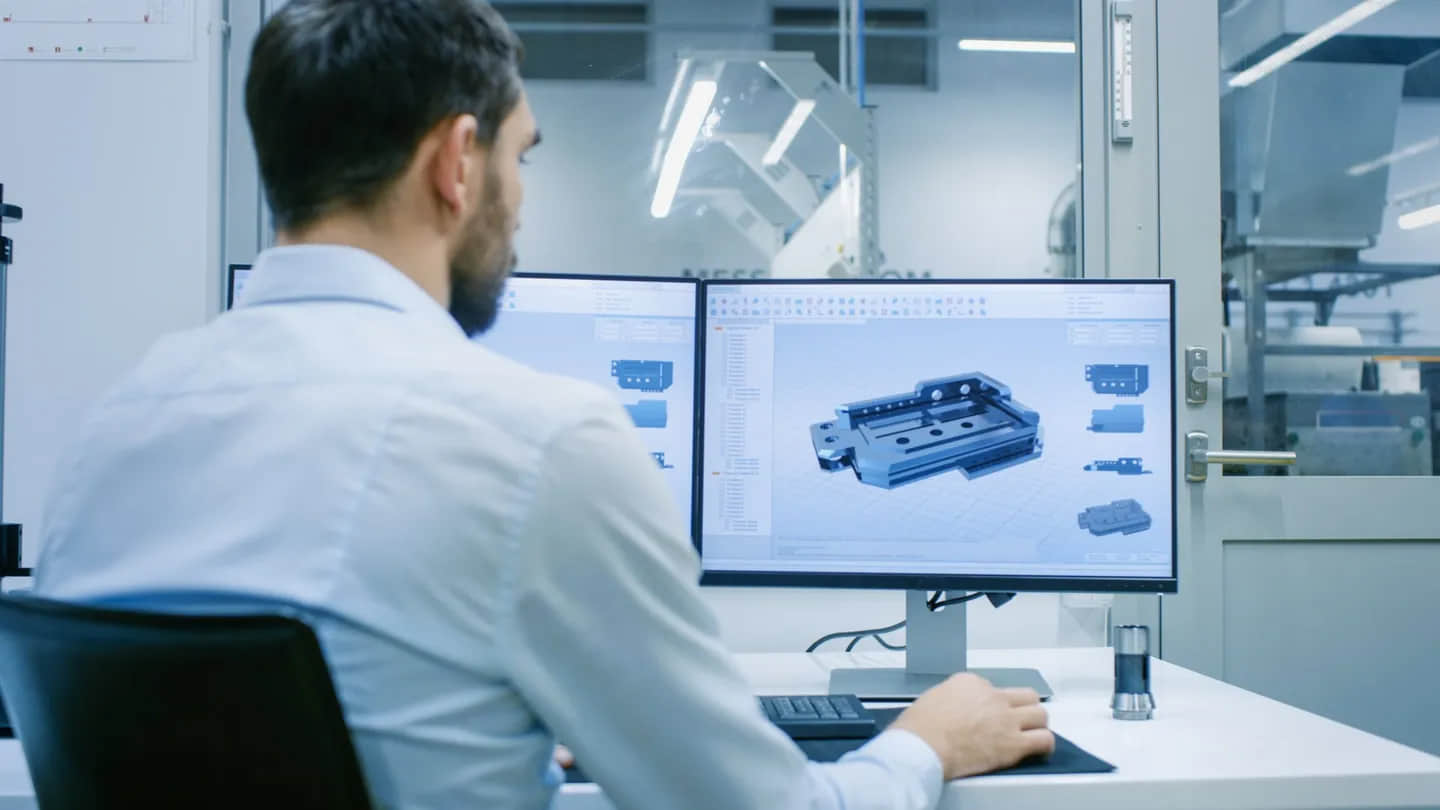

Experienced Project Engineers

Our professional project engineers have full industry expertise from

materials to injection molding production and have more than 10 years of molding experience.

This is

the key to our success in taking a concept to the final product.

More Details>>

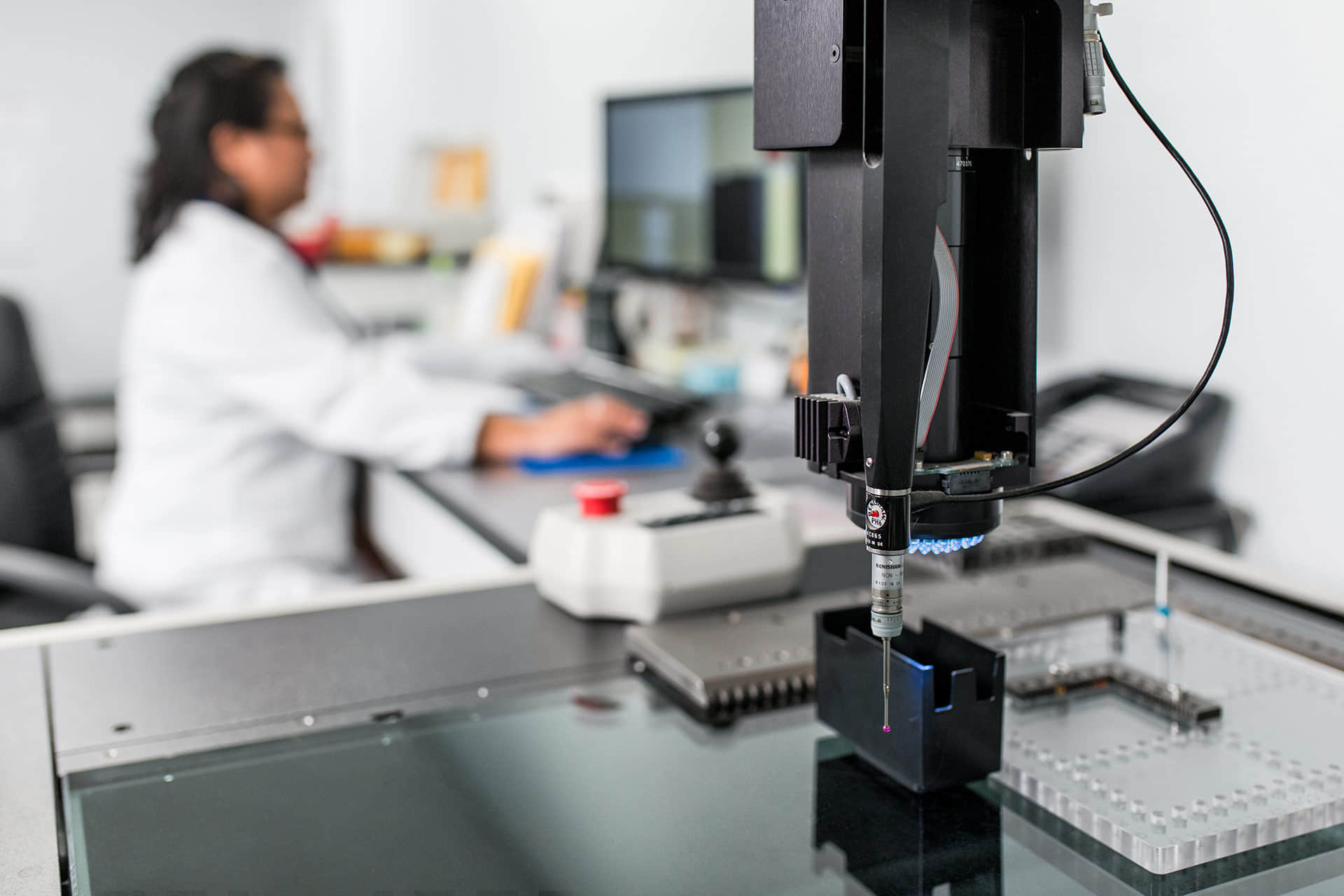

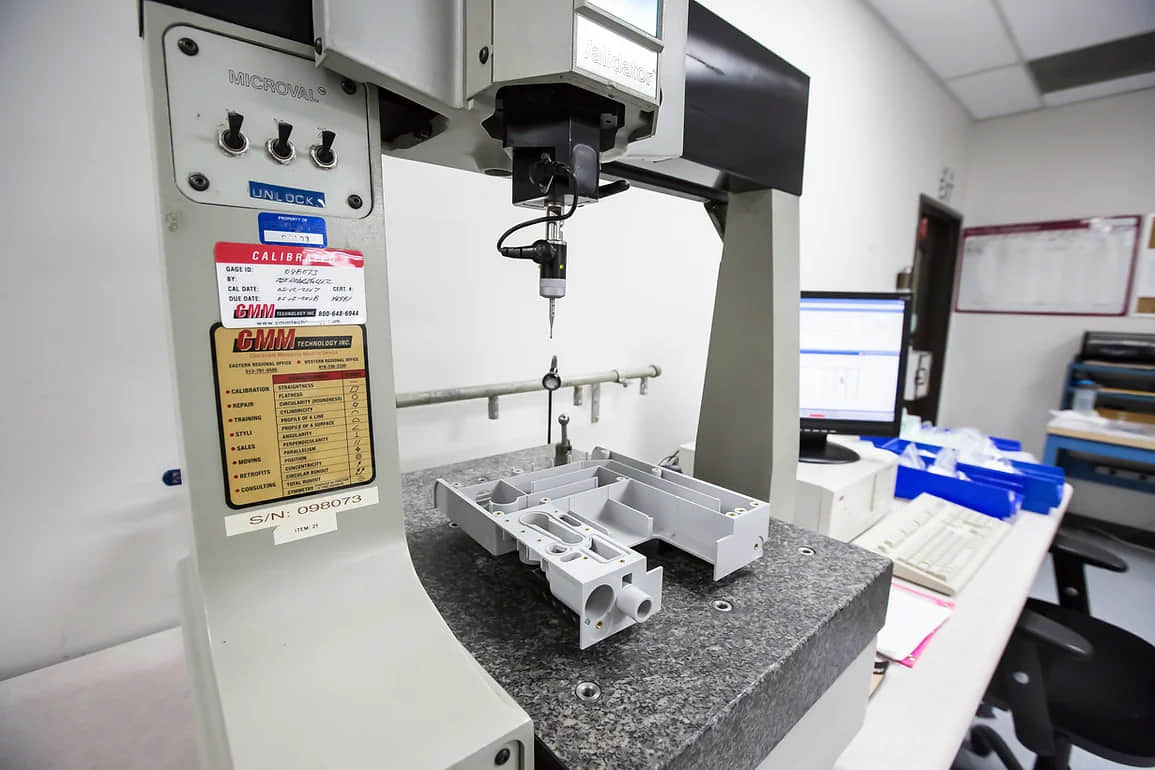

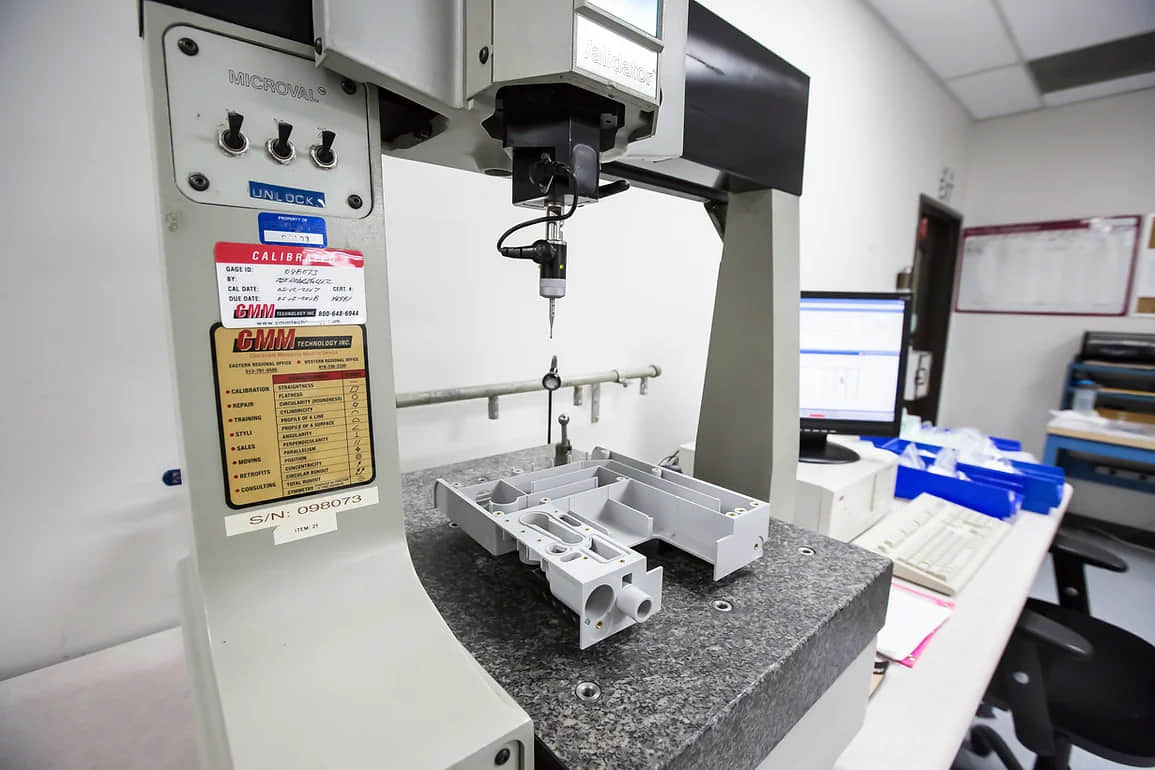

Rigorous Inspection

Inspection plays an important role in our entire production process. Our Quality Control (QC)

staff

carry out a comprehensive range of inspections, including incoming material inspection, first

article inspection, routing inspection, and finished product inspection.

More Details>>

Quality Control Practices

Standardized quality control measures are designed to ensure that the final product meets specified standards

and customer requirements, minimizes defects and maintains consistent quality.

Pre-production

Before production begins, our engineering team will conduct a comprehensive

assessment (DFM) of

your parts, including: material selection,Before production begins, our engineering

team will conduct a comprehensive assessment (DFM) of

your parts, including: material selection,surface finish, structural defects,

process, etc. The

purpose of a comprehensive assessment is to identify potential risks and determine

the

probability of feasibility.

Verify material conformity with production plan. We provide certification of the

materials used

to manufacture your parts. Reports come from raw material manufacturers and usually

include

details of material grade, chemical composition, mechanical properties, material

properties,

etc.

In-production

Before the formal production, you can refer to the sample or drawings for the first

article

inspection, and start production after confirm no problems.

We strictly comply with the ISO9001:2015 quality control plan. Our quality control

staff

perform

routine checks on all parts in production every 2 hours. Further prevent the

occurrence

of

risks.

Final Production

For any part, we can provide a full dimension inspection report or critical

dimension report

according to the customer request.

Confirm the correct packaging method, instructions and other accessories into the

box in

time to

prevent packaging quality problems. In order to prevent damage in transit, according

to

customer

requirements, we provide a variety of protective packaging, such as inside and

outside

cartons,

pearl cotton, foam, wooden house etc., to ensure customers receive the highest

quality

products.

Ture Customer Satisfaction

We strive for excellence in injection molding manufacturing. We never compromise on quality and our strict

quality management system

helps us deliver parts to specifications. With all our experience in engineering, design, manufacturing,

quality

and attention to detail, you can rely on Attractive Plastics to deliver. We utilize all these techniques and

more.

-

Failure Mode And Effects Analysis (FMEA)

-

Define, Measure, Analyze, Improve Control (DMAIC)

-

Advanced Product Quality Planning(APQP)

-

Corrective and Preventive Action (CAPA)

-

Production Part Approval Process (PPAP)

-

Statistical Process Control (SPC)

-

8D Corrective Action System featuring 5-Why root cause analysis

Quality Report

Certificate of Conformance

For any order, we will issue a certificate of conformance proving that the order has been made

according to the required specifications.

Download Template

Material Physical Properties Report

Material property report is the basic information of materials and an important basis for

material

selection.

Download Template

Dimensional Report

For plastic parts with assembly needs, whether full size or critical size, it is the focus of

attention in production.

Download Template

Rohs Report

Our materials fully comply with EU ROHS regulations and provide relevant test reports.

Download Template

First Article

Inspection (FAI)

For any order, we will issue a certificate of conformance proving that the order has been made

according to the required specifications.

Download Template

Reach Report

Our materials REACH report indicates that our products fully comply with the requirements of the

EU

REACH Regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals)

Download Template

Inspection Equipment

-

Vernier Calipers

-

Micrometers

-

Gauge blocks

-

RAL/Pantone color charts

-

Coordinate Measuring Machine (CMM)

-

Height gauge

-

Surface roughness meter

-

Protractors

-

Feeler gauge

-

Pin gauges

-

Hardness Tester

-

Thread, ring and plug Go/No-Go gauges

Are You Looking to Become More Competitive? let's discuss your project.

Get a Quote Now

Or Sent Us E-mail: info@attractiveplastics.com