| Mold-Tech A Finishes | |||

| NO. | Texture Depth (Inch) | Texture Depth (mm) | Minimun Draft (°) |

| MT-11000 | 0.0004 | 0.01016 | 1 |

| MT-11010 | 0.001 | 0.0254 | 1.5 |

| MT-11020 | 0.0015 | 0.0381 | 2.5 |

| MT-11030 | 0.002 | 0.0508 | 3 |

| MT-11040 | 0.003 | 0.0762 | 4.5 |

| MT-11050 | 0.0045 | 0.1143 | 6.5 |

| MT-11060 | 0.003 | 0.0762 | 4.5 |

| MT-11070 | 0.003 | 0.0762 | 4.5 |

| MT-11080 | 0.002 | 0.0508 | 3 |

| MT-11090 | 0.0035 | 0.0889 | 5.5 |

| MT-11100 | 0.006 | 0.1524 | 9 |

| MT-11110 | 0.0025 | 0.0635 | 4 |

| MT-11120 | 0.002 | 0.0508 | 3 |

| MT-11130 | 0.0025 | 0.0635 | 4 |

| MT-11140 | 0.0025 | 0.0635 | 4 |

| MT-11150 | 0.00275 | 0.06985 | 4 |

| MT-11160 | 0.004 | 0.1016 | 6 |

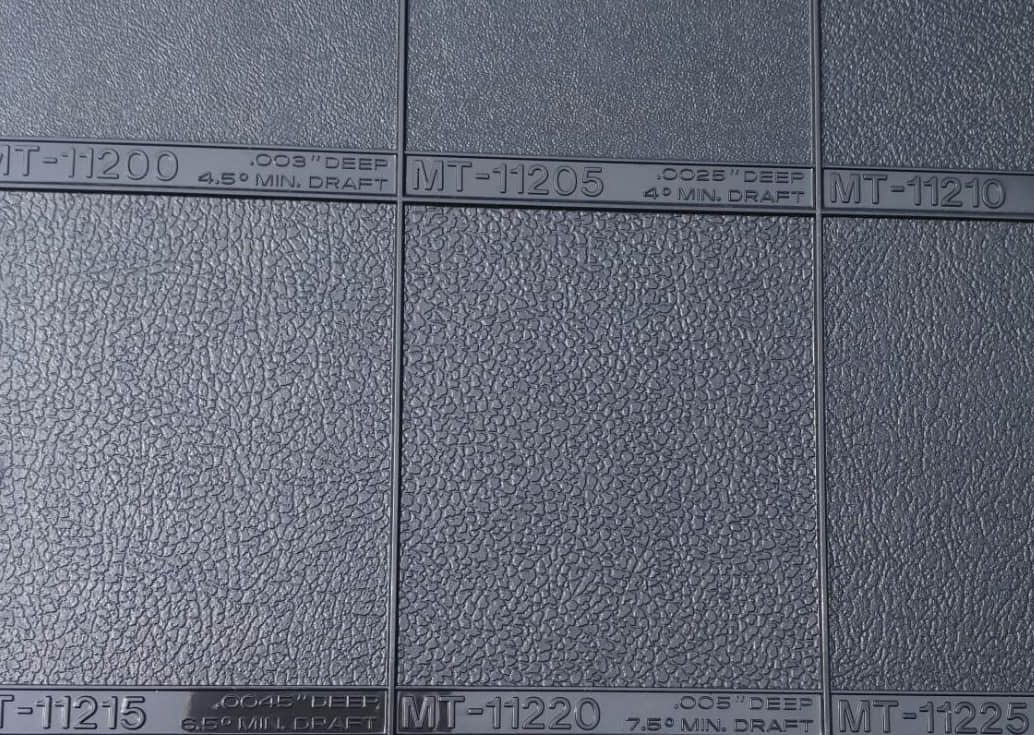

| Mold-Tech B Finishes | |||

| NO. | Texture Depth (Inch) | Texture Depth (mm) | Minimun Draft (゚) |

| MT-11200 | 0.003 | 0.0762 | 4.5 |

| MT-11205 | 0.0025 | 0.0635 | 4 |

| MT-11210 | 0.0035 | 0.0889 | 5.5 |

| MT-11215 | 0.0045 | 0.1143 | 6.5 |

| MT-11220 | 0.005 | 0.127 | 7.5 |

| MT-11225 | 0.0045 | 0.1143 | 6.5 |

| MT-11230 | 0.0025 | 0.0635 | 4 |

| MT-11235 | 0.004 | 0.1016 | 6 |

| MT-11240 | 0.0015 | 0.0381 | 2.5 |

| MT-11245 | 0.002 | 0.0508 | 3 |

| MT-11250 | 0.0025 | 0.0635 | 4 |

| MT-11255 | 0.002 | 0.0508 | 3 |

| MT-11260 | 0.004 | 0.1016 | 6 |

| MT-11265 | 0.005 | 0.127 | 7 |

| MT-11270 | 0.004 | 0.1016 | 6 |

| MT-11275 | 0.0035 | 0.0889 | 5 |

| MT-11280 | 0.0055 | 0.1397 | 8 |

| Mold-Tech C Finishes | |||

| NO. | Texture Depth (Inch) | Texture Depth (mm) | Minimun Draft (゚) |

| MT-11300 | 0.0025 | 0.0635 | 3.5 |

| MT-11305 | 0.005 | 0.127 | 7.5 |

| MT-11310 | 0.005 | 0.127 | 7.5 |

| MT-11315 | 0.001 | 0.0254 | 1.5 |

| MT-11320 | 0.0025 | 0.0635 | 4 |

| MT-11325 | 0.003 | 0.0762 | 4.5 |

| MT-11330 | 0.002 | 0.0508 | 3 |

| MT-11335 | 0.002 | 0.0508 | 3 |

| MT-11340 | 0.003 | 0.0762 | 4.5 |

| MT-11345 | 0.003 | 0.0762 | 4.5 |

| MT-11350 | 0.0035 | 0.0889 | 5.5 |

| MT-11355 | 0.0025 | 0.0635 | 4 |

| MT-11360 | 0.0035 | 0.0889 | 5.5 |

| MT-11365 | 0.0045 | 0.1143 | 7 |

| MT-11370 | 0.004 | 0.1016 | 6 |

| MT-11375 | 0.004 | 0.1016 | 6 |

| MT-11380 | 0.004 | 0.1016 | 6 |

| Mold-Tech D Finishes | |||

| NO. | Texture Depth (Inch) | Texture Depth (mm) | Minimun Draft (゚) |

| MT-11400 | 0.002 | 0.0508 | 3 |

| MT-11405 | 0.0025 | 0.0635 | 4 |

| MT-11410 | 0.0035 | 0.0889 | 5.5 |

| MT-11415 | 0.002 | 0.0508 | 3 |

| MT-11420 | 0.0025 | 0.0635 | 4 |

| MT-11425 | 0.0035 | 0.0889 | 5.5 |

| MT-11430 | 0.007 | 0.1778 | 10 |

| MT-11435 | 0.01 | 0.254 | 15 |

| MT-11440 | 0.0005 | 0.0127 | 1.5 |

| MT-11445 | 0.0015 | 0.0381 | 2.5 |

| MT-11450 | 0.0025 | 0.0635 | 4 |

| MT-11455 | 0.003 | 0.0762 | 4.5 |

| MT-11460 | 0.0035 | 0.0889 | 5.5 |

| MT-11465 | 0.005 | 0.127 | 7.5 |

| MT-11470 | 0.002 | 0.0508 | 3 |

| MT-11475 | 0.002 | 0.0508 | 3 |

| MT-11480 | 0.003 | 0.0762 | 4.5 |

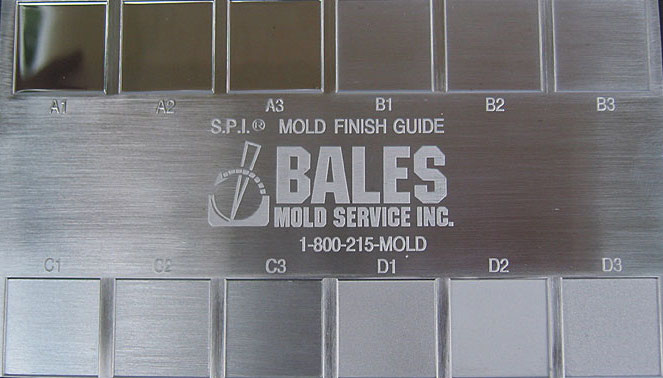

A SPI Mold Classification is a system used to categorize molds based on their quality and performance. SPI stands for “Society for the Promotion of injection Molding” and was developed as a way to standardize mold evaluation and classification methods. This classification system provides clear guidelines for quoting and ordering molds according to the production needs, with options available.

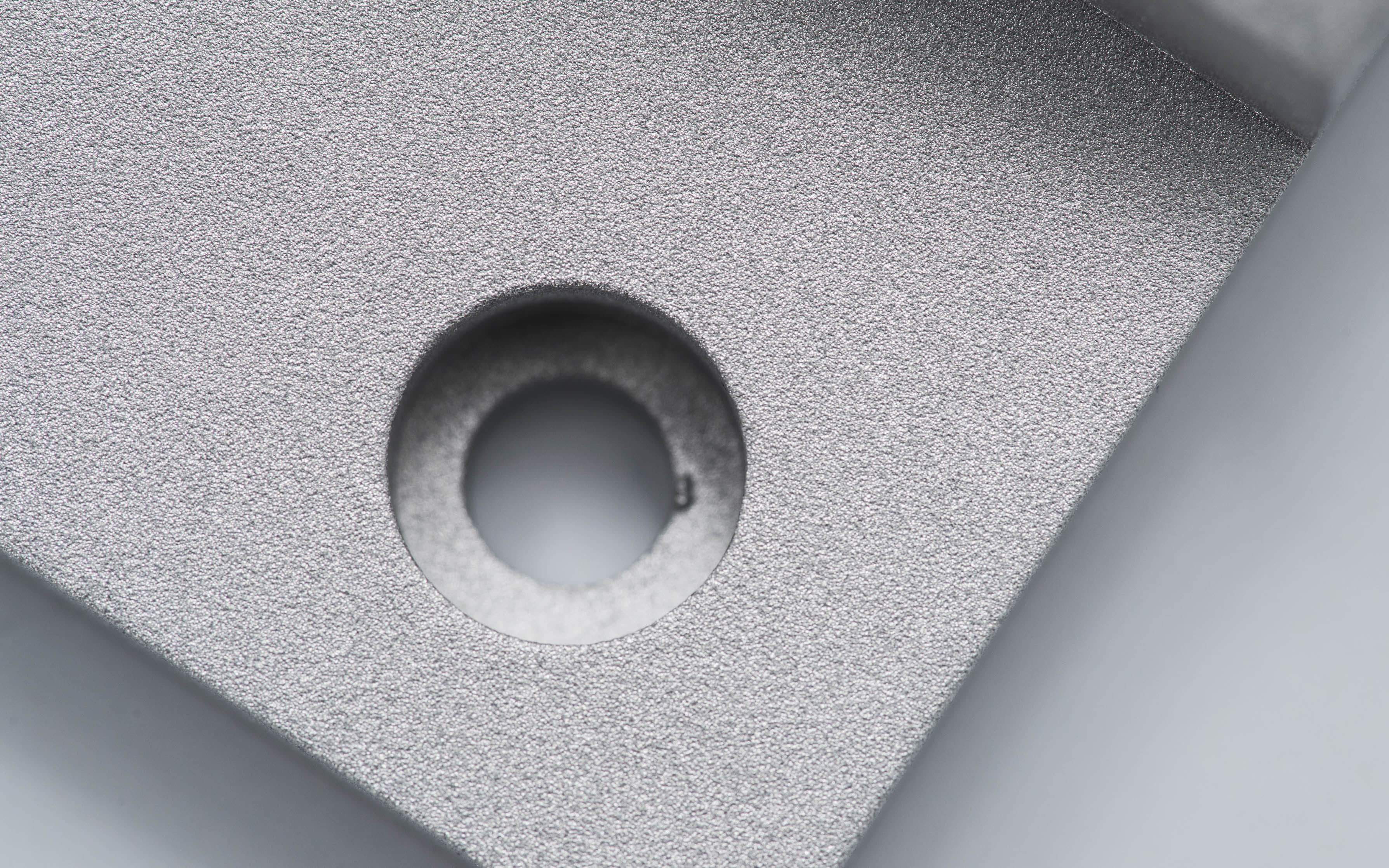

Surface finishes refer to the texture and appearance of the surface of a manufactured product. It is an important indicator reflecting the micro-geometric shape errors on the surface of parts. Some also refer to it as surface roughness, but that is not entirely accurate. In fact, Surface finish is composed of three distinct elements – roughness, lay, and waviness. it mainly describes the degree of unevenness on the component’s surface, which is composed of minor peaks, valleys and wavelengths. Surface finish is closely related to the fitting performance, wear resistance, fatigue strength, contact stiffness, appearance and other aspects of mechanical parts.

We provide over 100 surface finish options for your plastic products. The most common surface finish used for injection molded parts include SPI-SPE, MOLD-TECH, VDI, bead blasting etc.

SPI surface finish refers to the surface finish standard established by the Plastics Industry Trade Association (SPI). It classifies surface finish into 12 levels. A to D represent surface finish from rough to smooth.

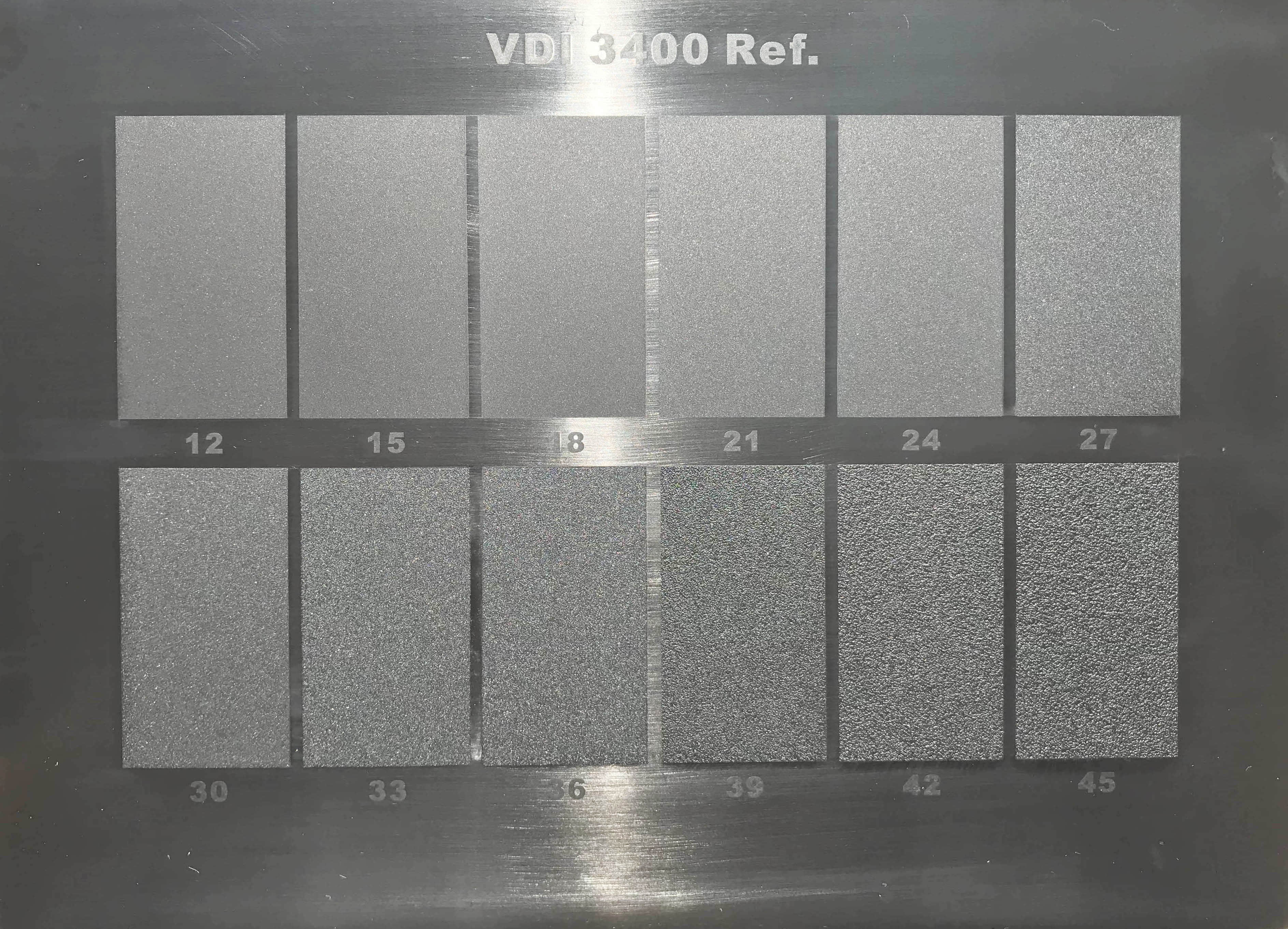

VDI 3400 Surface Finish (commonly known as VDI surface finish) refers to the mold texture standard established by Verein Deutscher Ingenieure (VDI), the Society of German Engineers. The VDI 3400 surface finish is primarily machined by electrical discharge machining (EDM). It can also be done through traditional texturing methods (such as SPI, laser).