2000+

Companies Served

99%

On time delivery In 2022

50+

Million Parts In 2022

99%

Defect Free In 2022

20+

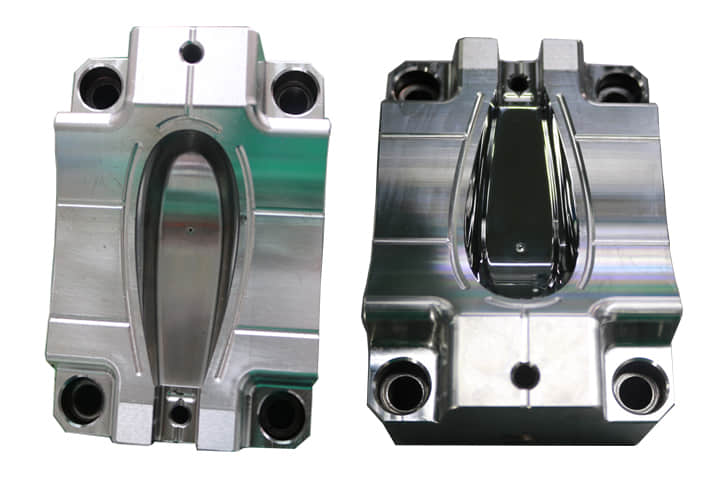

Years In Injection Molidng Industry

30+

Countries Shipped

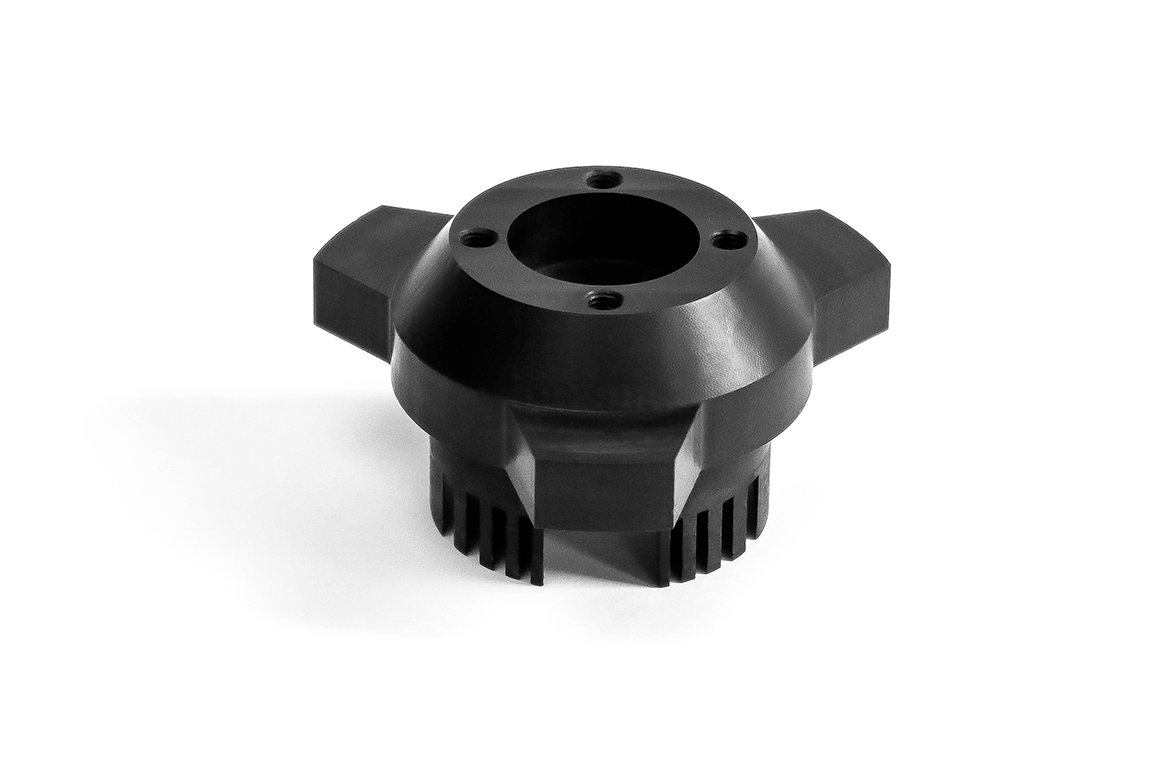

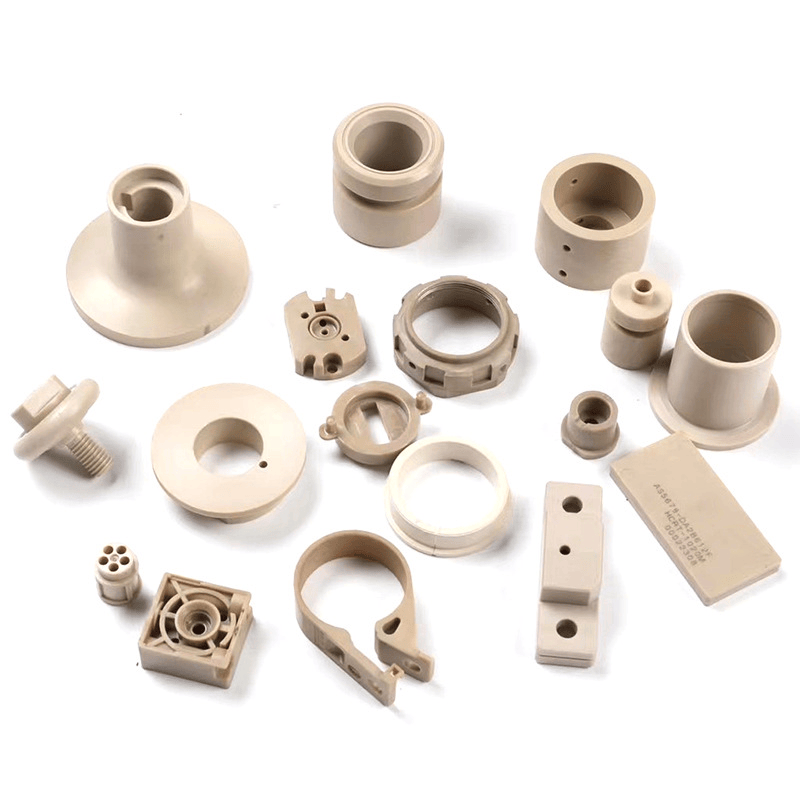

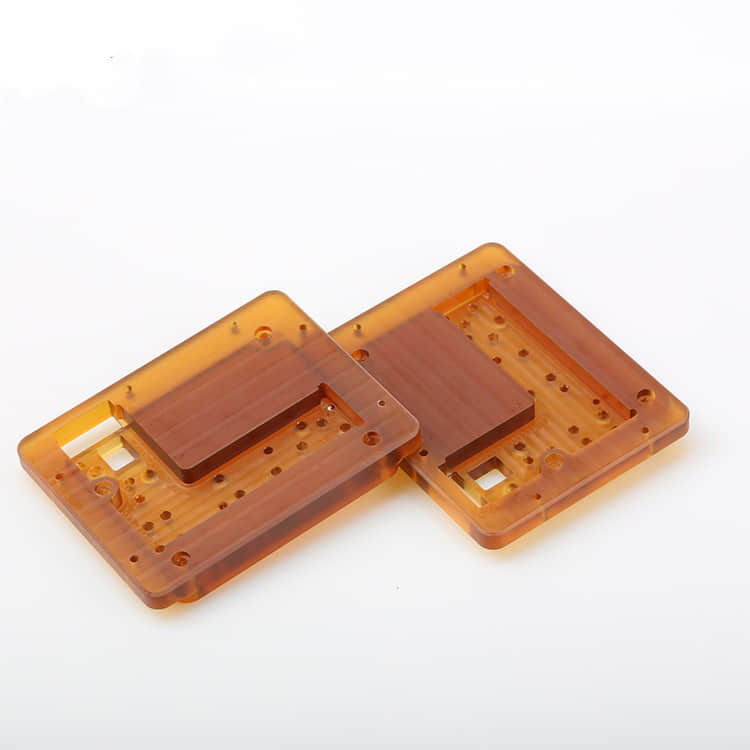

Consistent High Quality

Consistent High Quality

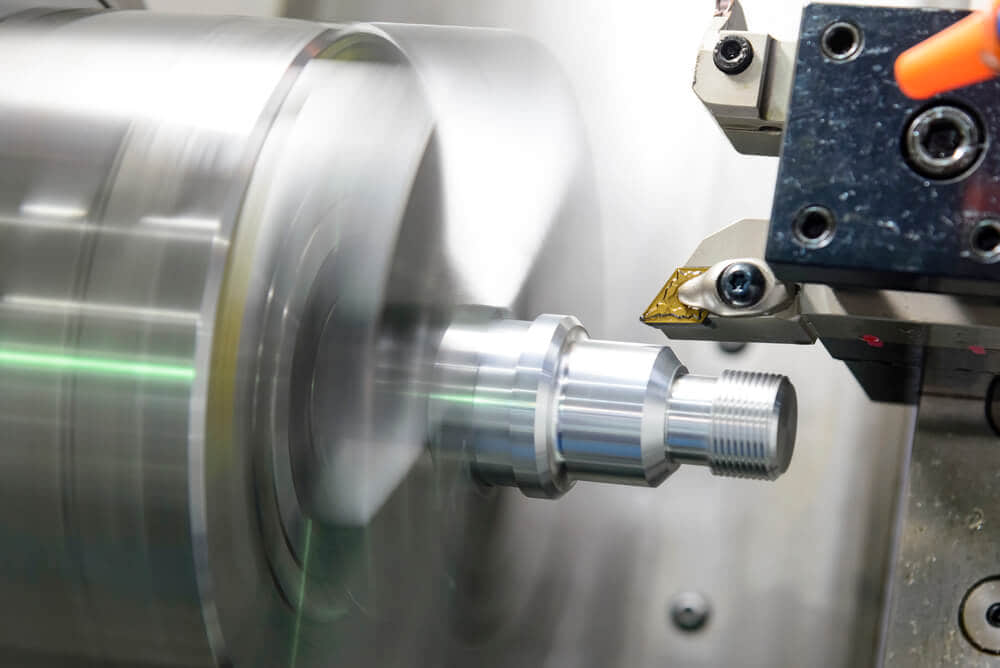

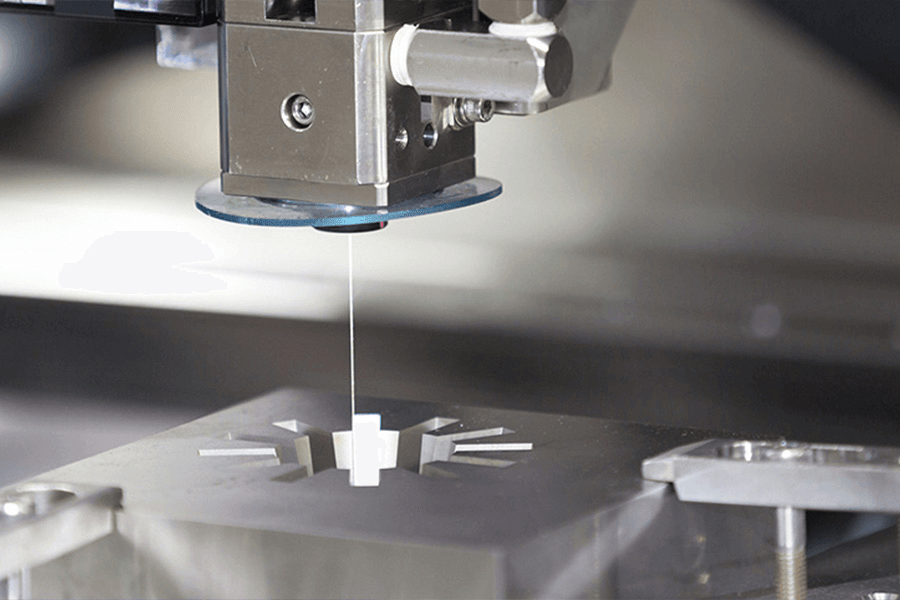

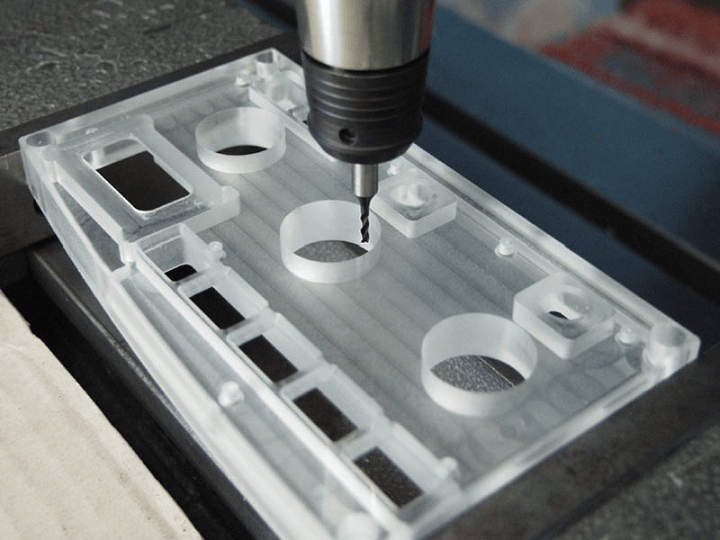

Advance Equipments

Advance Equipments

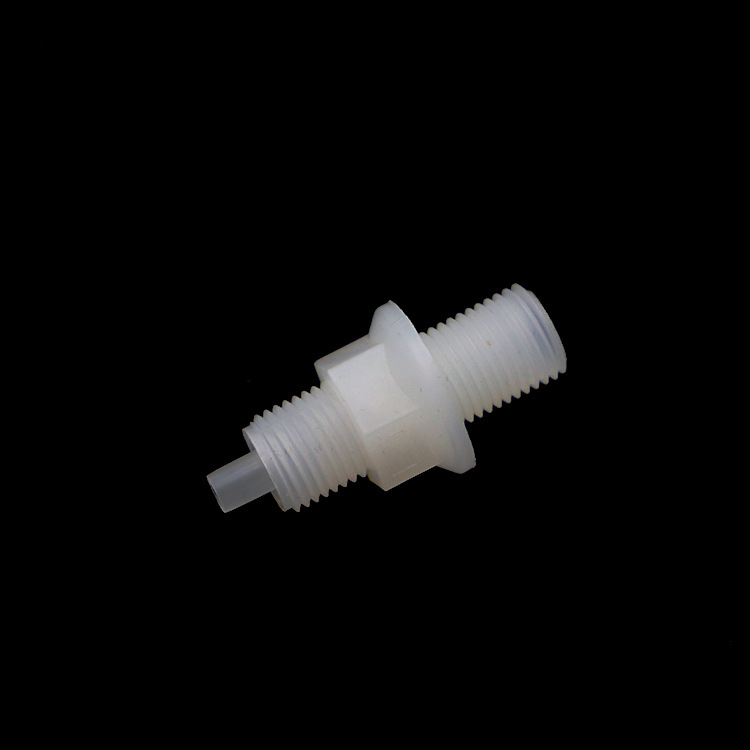

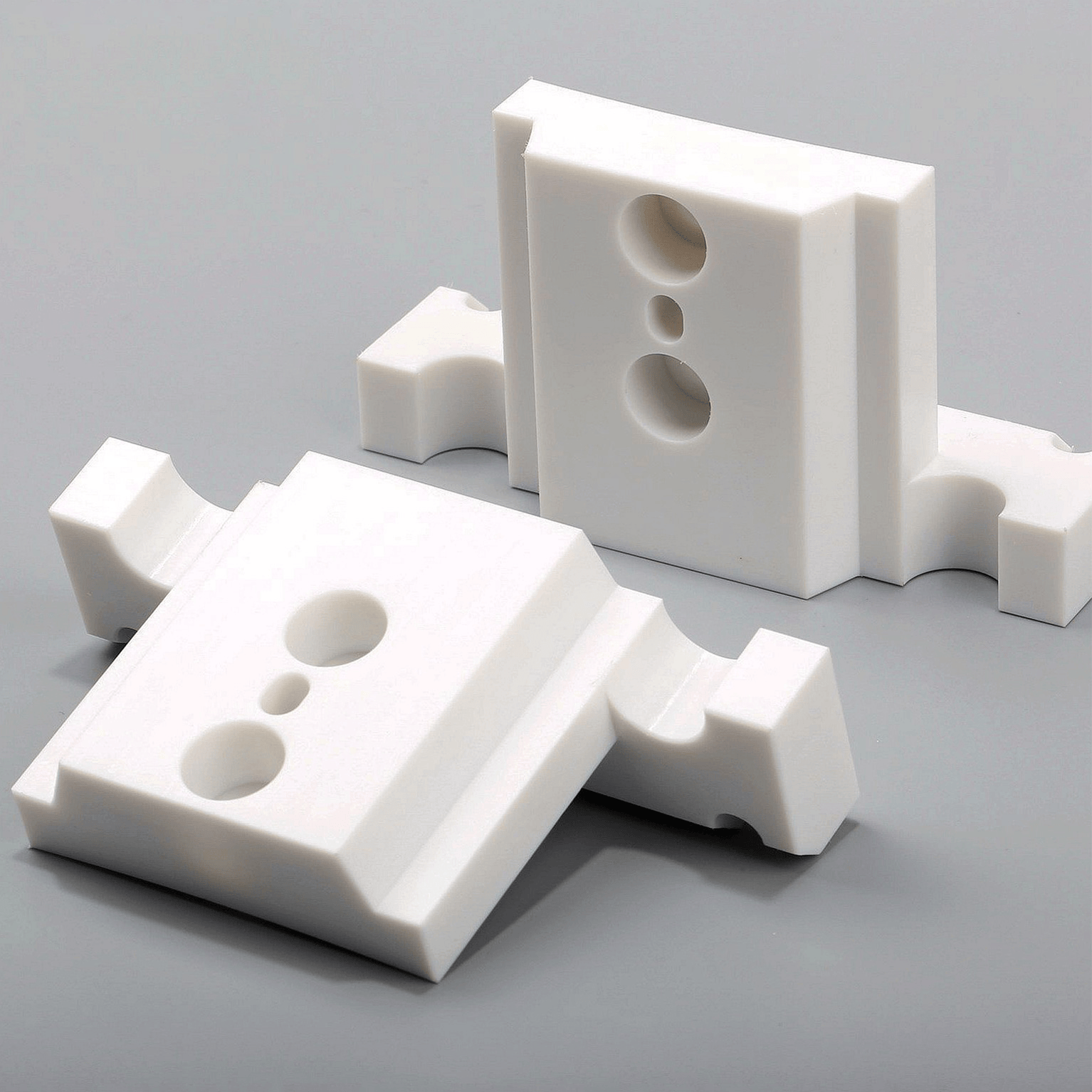

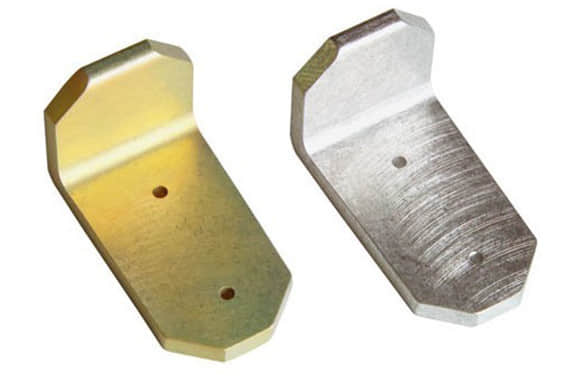

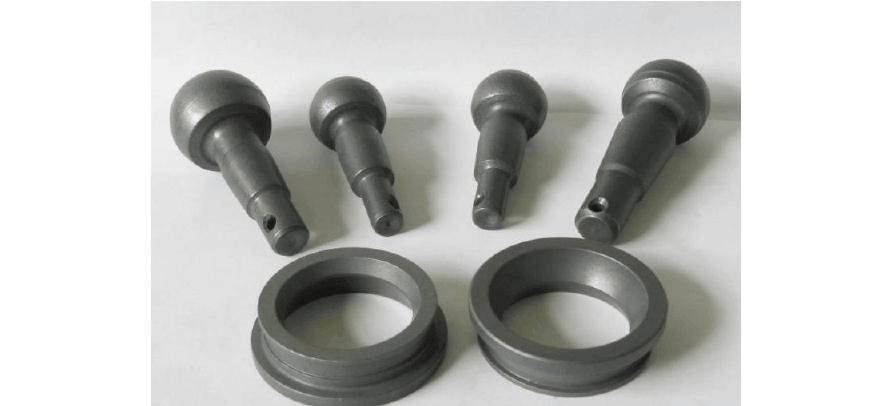

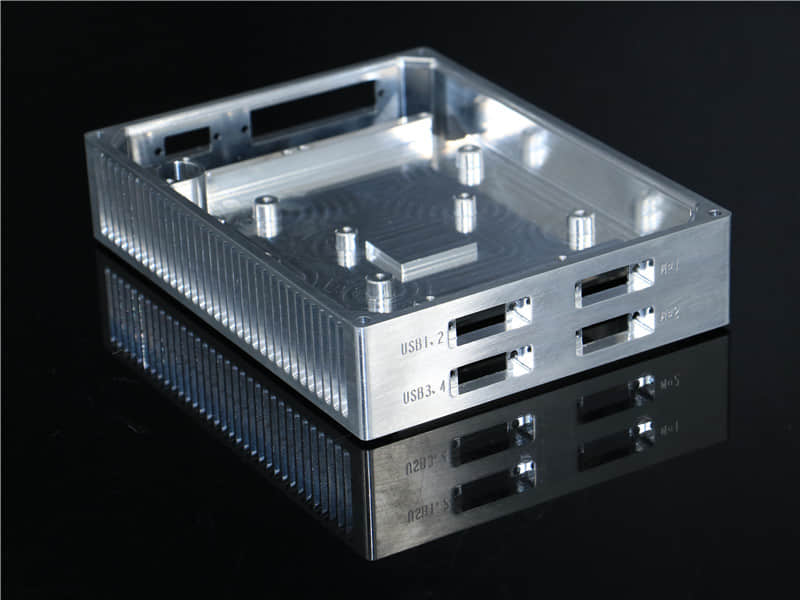

We offer the following machining services: milling, turning, sinker EDM and wire EDM, drilling, threading, tapping, prototyping, surface finishes etc.

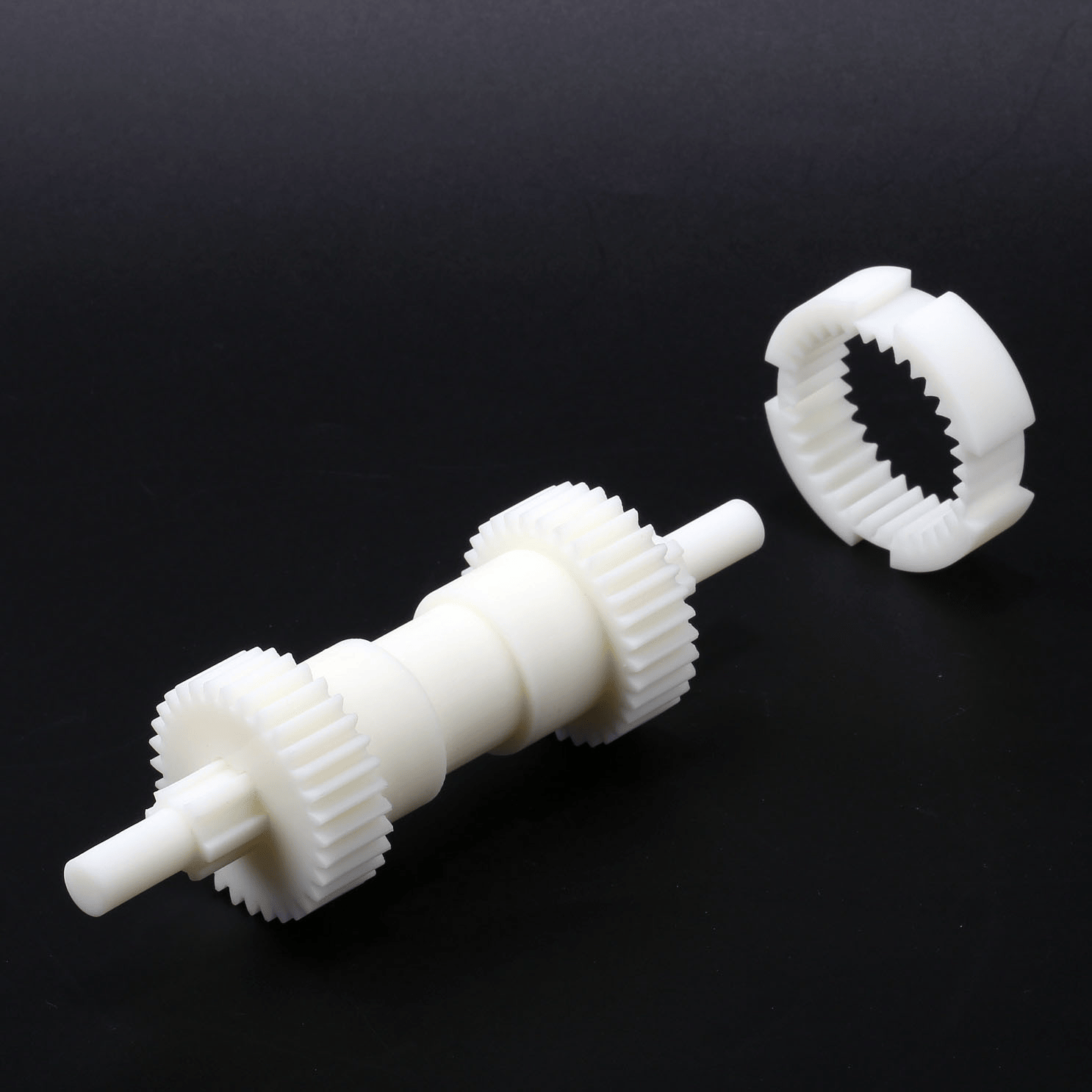

Different parts have different costs. The complexity and materials of the parts determine the price of the parts. The price usually needs to be evaluated based on the specific part structure. Contact our engineering and sales teams who will provide one-on-one quote support for your project.

We offer a variety of lead time to match your budget while maintaining your project timeline. Lead time usually ranges from 3 working days to a few weeks depending on the complexity of the part and the quantity ordered.

In most cases, we will respond to your quote within 24 hours. If the product is particularly complex, we will also inform you in advance. To ensure a quick quote, it is best to provide as much accurate product-related information as possible.

Our machines are available with minimum tolerances of +/-0.0002 inches.

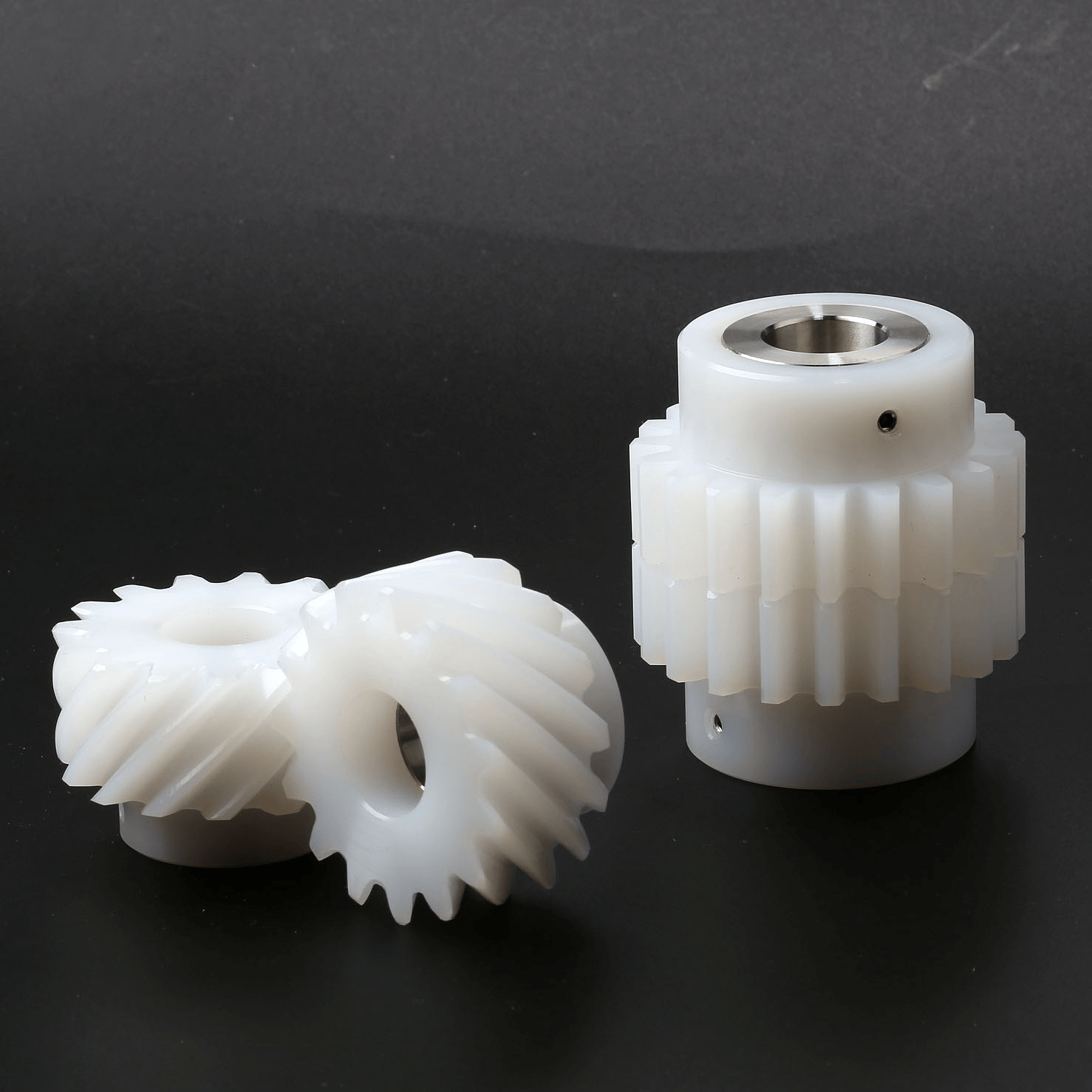

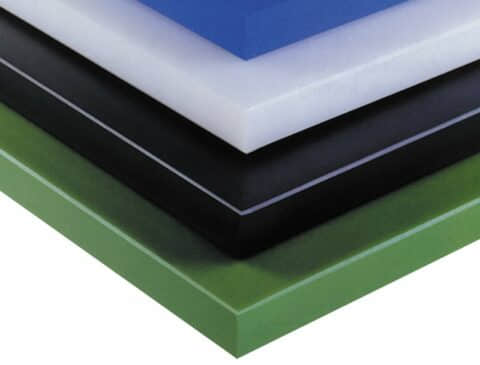

We support CNC machining of various metal and plastic materials, such as: Aluminum, steel, copper, Stainless Steel, Magnesium, Titanium, Zinc, Inconel alloy, Monel Alloy, ABS, Nylon, PMMA, PEEK, PEI, PTFE etc.

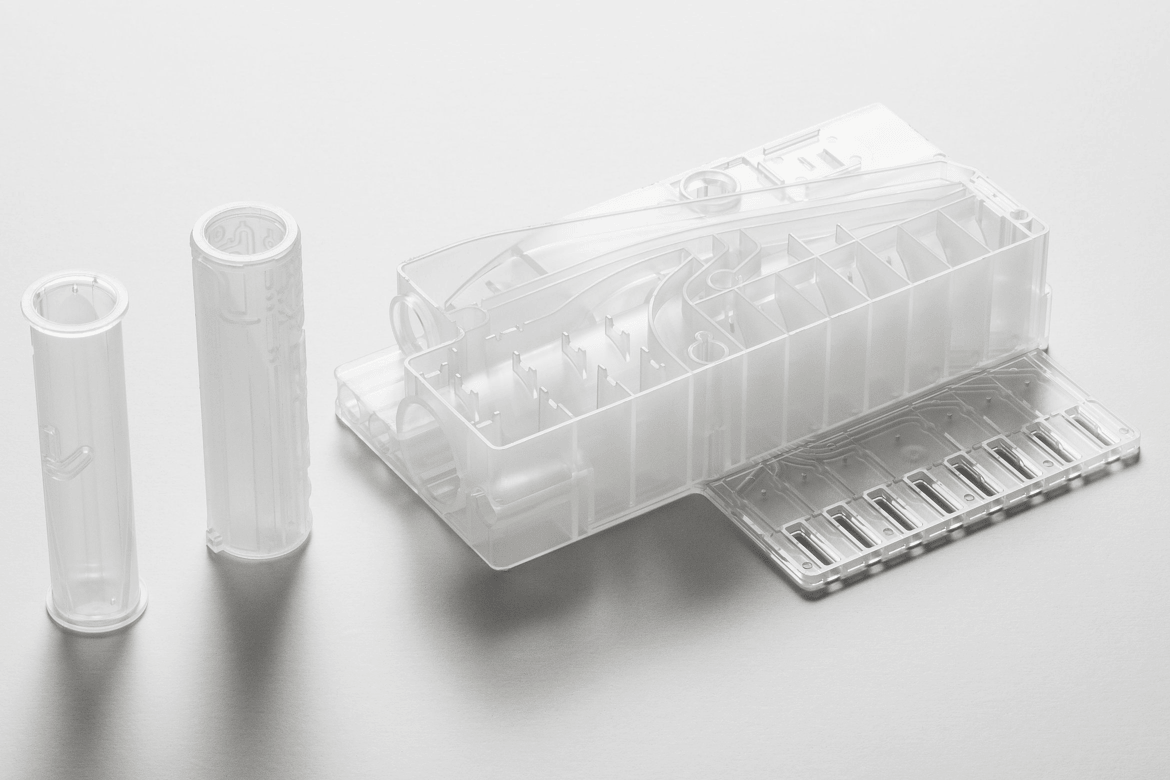

No problem, We do our best to meet your delivery time requirements, Our injection mold delivery time is 10 days, injection production, the shortest 3 days delivery. Of course, this depends on the complexity of the application.

Yes, free quotes and Design for Manufacturability (DFM) feedback are provided to all our customers. If you have any questions about your product, contact our engineers and they will provide you with a more reliable solution for your project.