High Quality

High Quality

Multiple post molding treatment

Multiple post molding treatment

Fast Delivery

Fast Delivery

Cost-Effectiveness

Cost-Effectiveness

Water transfer printing and heat transfer printing are both methods of transferring patterns or text to the surface of injection molded products. Water transfer printing is to soak the transfer film with patterns or text in water, then stick it on the surface of the product, and transfer the pattern or text to the product through water pressure. Thermal transfer printing is to heat the transfer film with patterns or text and stick it on the surface of the product, and transfer the pattern or text to the product through high temperature.

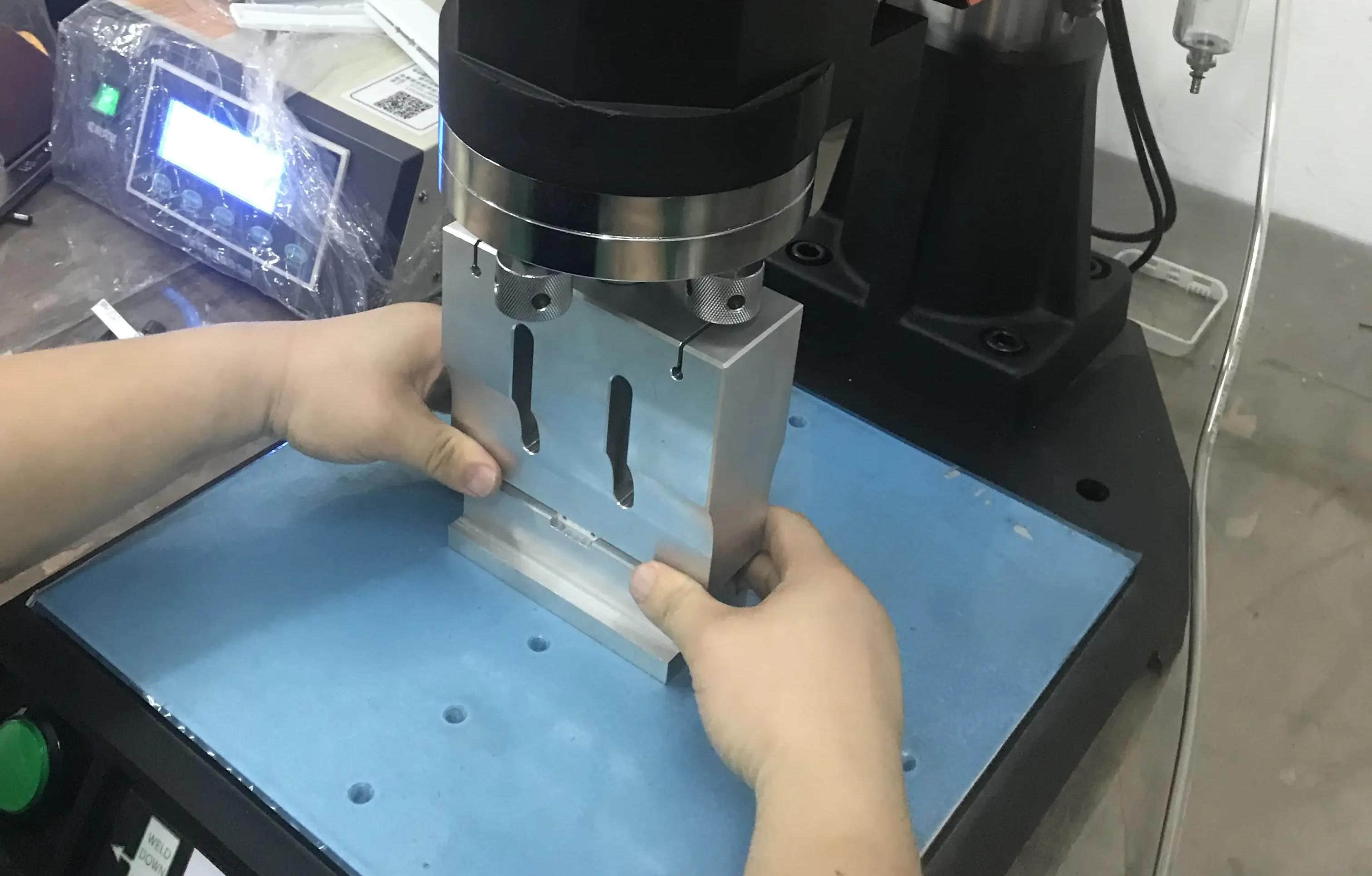

The post-molding services we can provide include: electroplating, spray painting, silk screen printing, pad printing, thermal transfer printing, hot stamping, ultrasonic welding, electroplating, spin welding, assembly, etc.

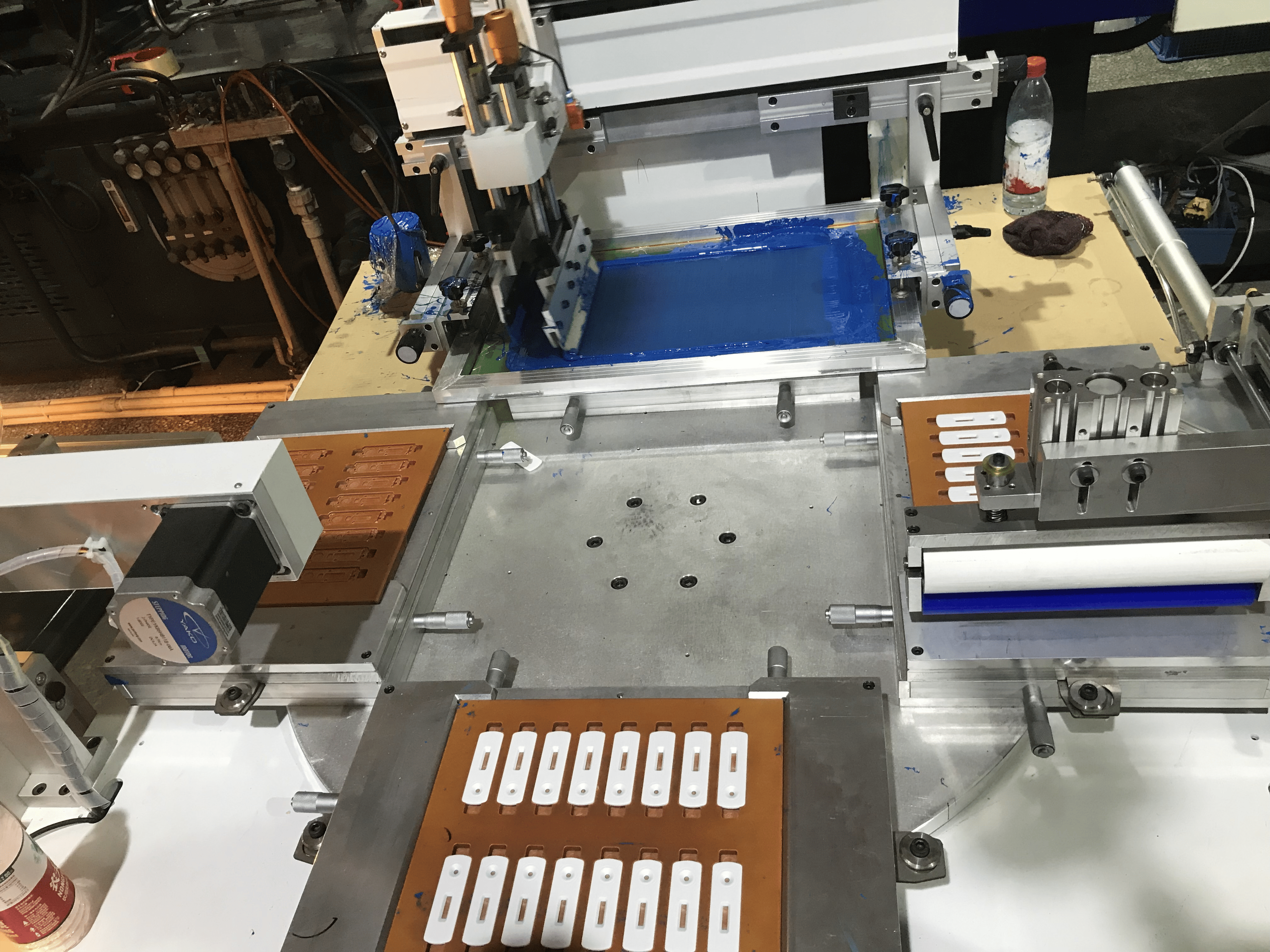

Commonly used plastic parts printing include silk screen printing, pad printing, heat transfer printing, hot stamping, etc.

1. Hand spraying

The surface of the product is directly sprayed with oil through manual operation. It is currently used for manual spraying of defective products after automatic spraying.

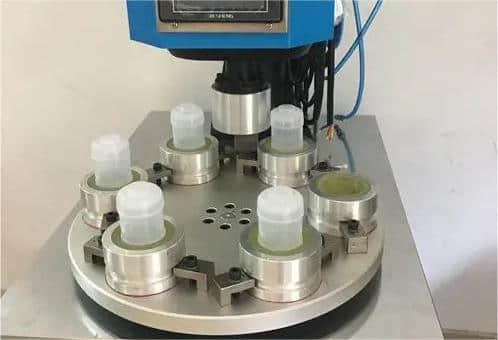

2. Fully automatic spraying

The products that need to be sprayed are fixed on the rotatable bracket, and then the bracket is locked on the assembly line, and then the assembly line is moved at a fixed rate and the rotatable bracket is rotated continuously to achieve 100% uniform spraying on the product surface.

Screen printing is a popular printing technique used to transfer ink to a variety of surfaces, such as fabric, paper, glass, and plastic. It is widely used in the production of textiles, posters, signs, promotional items, etc. The process involves the following steps:

Step 1: Make a screen printing plate: According to the product requirements, design the screen printing plate and produce a screen printing plate that meets the requirements.

Step 2: Determine the printing process parameters: According to the product material and specifications, determine the appropriate printing process parameters, including screen mesh number, screen material, printing speed, printing pressure, drying method, etc.

Step 3: Prepare the screen printing machine: Prepare the screen printing machine according to the printing process parameters, and perform necessary debugging and calibration.

Step 4: Screen printing: Place the screen printing plate on the screen printing machine, pour the ink onto the screen printing plate, and print through the screen printing machine to evenly print the ink on the surface of the product.

Step 5: Drying: According to the product material and specifications, use appropriate drying methods to quickly dry the printed ink.

Step 6: Quality inspection: Conduct quality inspection on printed products, including printing accuracy, printing effect, ink adhesion, etc.

These are some common defects we have summarized based on our 15 years of experience in plastic products painting:

1. Phenomenon: Granulation

Reasons: The work site is unclean and dust is mixed into the paint; the paint is left for too long after being mixed, and the paint and curing agent have produced copolymerized particles; the oil output of the spray gun is too small and the air pressure is too high, resulting in poor atomization of the paint or the spray gun is away from the surface too close

Solution: Clean the spray booth and cover the paint bucket; the paint is well mixed and should not be left for too long; adjust the spray gun so that it is in the best working condition and make sure the distance between the gun muzzle and the object surface is 20-50CM.

2. Phenomenon: vertical flow

Cause: Excessive diluent makes the paint viscosity too low and loses viscosity; the oil output is too large, too close to the object surface or the spray operation is too slow; the amount of oil sprayed each time is too thick and too thick or the interval between re-spraying is too short; the object surface Uneven, especially streamlined shapes that tend to sag.

Solution: Proportion as required; control the amount of oil output to ensure that the spray distance is increased; increase the operating speed of the spray gun; each spray should not be too thick, and it is best to control the interval of spraying in two sprays; control the amount of oil output to reduce the thickness of the paint film; press Instructions for use ratio.

3. Phenomenon: orange peel

Reasons: Too much curing agent causes the paint film to dry too quickly and reacts violently; the spraying air pressure is too high, causing the paint film to wrinkle and become unable to level; the temperature at the job site is too high, causing the paint film to react violently

Solution: Follow the instructions for use; adjust the air pressure, not too high; pay attention to the temperature on site, and add slow-drying diluent to inhibit the drying speed.

4. Phenomenon: whitening

Reason: The temperature and humidity at the job site are high, and the paint film reacts violently, which may combine with moisture in the air to cause whitening; excessive curing agent, too much and too thick a spray at one time

Solution: Pay attention to the humidity on site, and add anti-whitening water to prevent the whitening phenomenon from occurring; adjust according to the proportion, and do not spray too thickly at one time

5. Phenomenon: Blistering

Original solid: water is mixed into the paint film in the compressed air, the temperature at the job site is high, and the paint dries too quickly; the moisture content of the surface is high, and the air humidity is high; one spray is too thick

Solution: Separate oil and water and pay attention to drainage; add slow-drying thinner; clean the surface and add anti-white water to the paint; it should not be too thick at one time

6. Phenomenon: Shrinkage

Reason: The primer or intermediate coat is not dry before applying the topcoat.

Solution: Spray according to the recommended thickness of each sweep gun spray coating

7. Phenomenon: Wrinkling

Reasons: The drying time is too short or the paint film is too thick; the curing agent in the primer or putty is improperly selected; the primer putty is incomplete; the gun is too thick when spraying the topcoat, and the internal deep agent does not evaporate in time, causing the outside to dry out and the inside to dry out. Don’t do it.

Solution: Allow sufficient drying time between each coat; only spray the second coat or spray wet after it is dry.