Increased Mechanical Properties

Increased Mechanical Properties

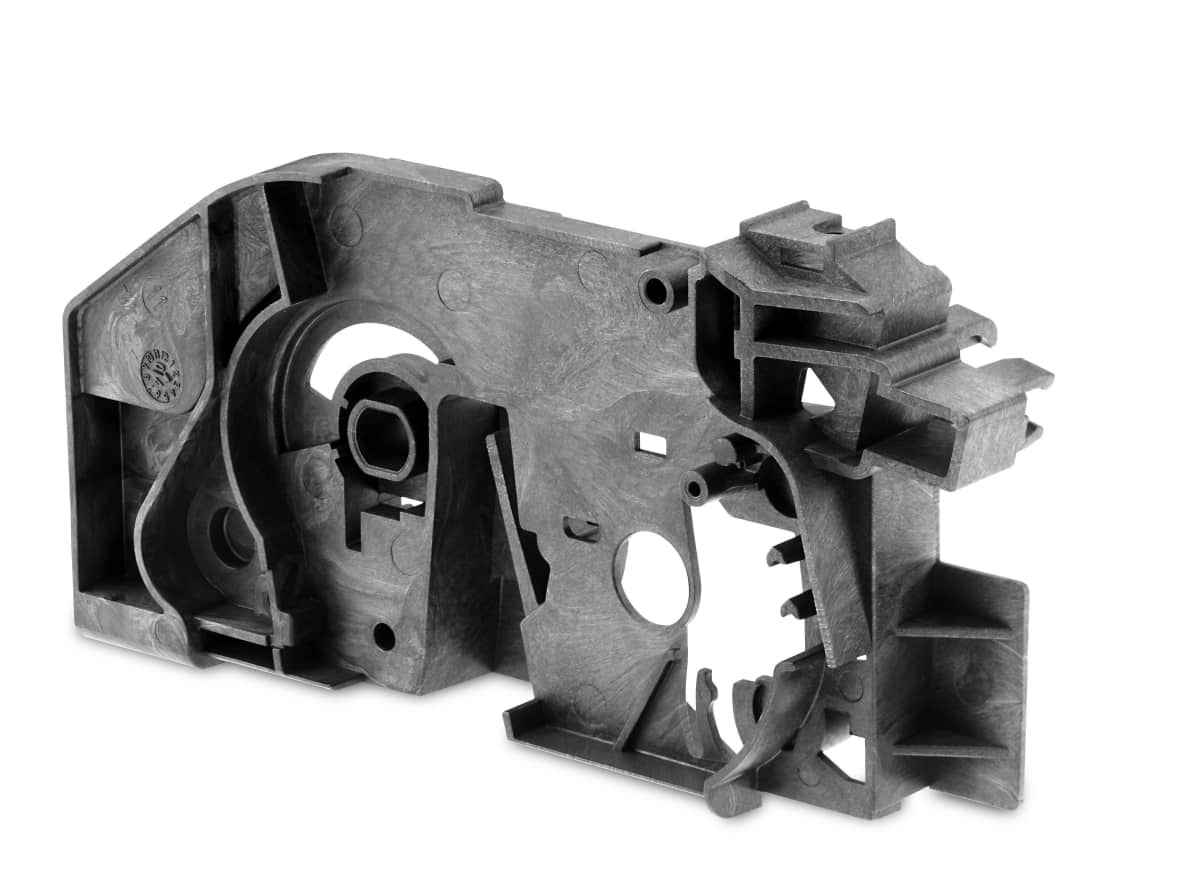

Increased design flexibility

Increased design flexibility

Improved Appearance

Improved Appearance

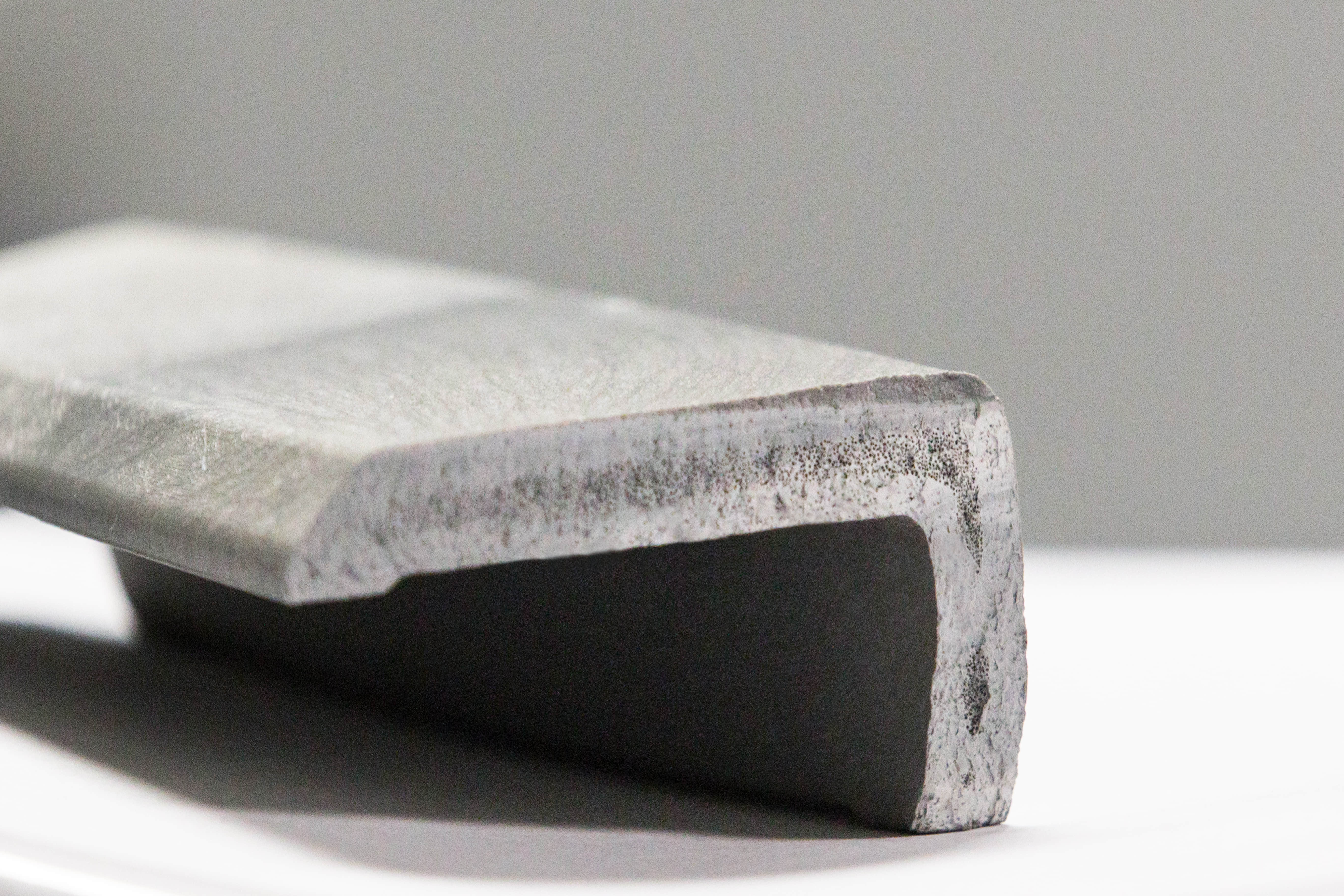

Structural foam injection molding is an injection molding process for producing strong, lightweight plastic parts with an interior foam structure. A gas is injected into the mold along with the polymer melt, resulting in an inner foamed core with a solid plastic skin. This provides weight reduction along with added strength and rigidity.

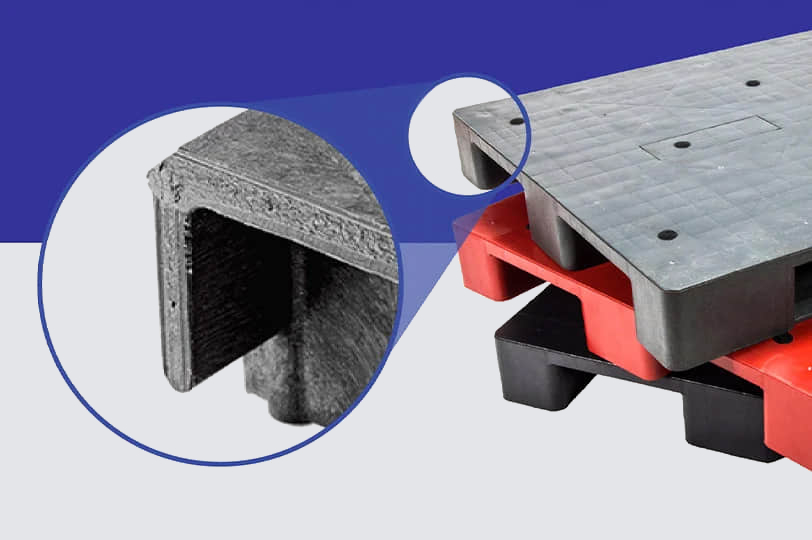

This molding process allows manufacturers to produce very large and thick plastic parts. Although it has some similarities to standard injection molding, this process requires much less pressure. As a result, parts may have thicker wall thicknesses while being lightweight and stiff.

During the injection molding process, the nitrogen produced by the chemical reaction of the foaming agent causes a foam core to be formed inside the plastic, resulting in a lightweight and high-strength structural foam injection molded part. Here is a brief overview of how structural foam injection molding works:

Structural foam molding provides an economical means of increasing strength, reducing weight, and improving dimensional stability of injection molded plastic parts. The process adds performance benefits without using expensive alloying or reinforcements.

Structural foam molding advantages:

The main challenges relate to higher equipment requirements, limitations on resin selection, increased process variability, and additional downstream operations. Proper design and process controls can minimize many of these disadvantages.

Structural foam molding disadvantages:

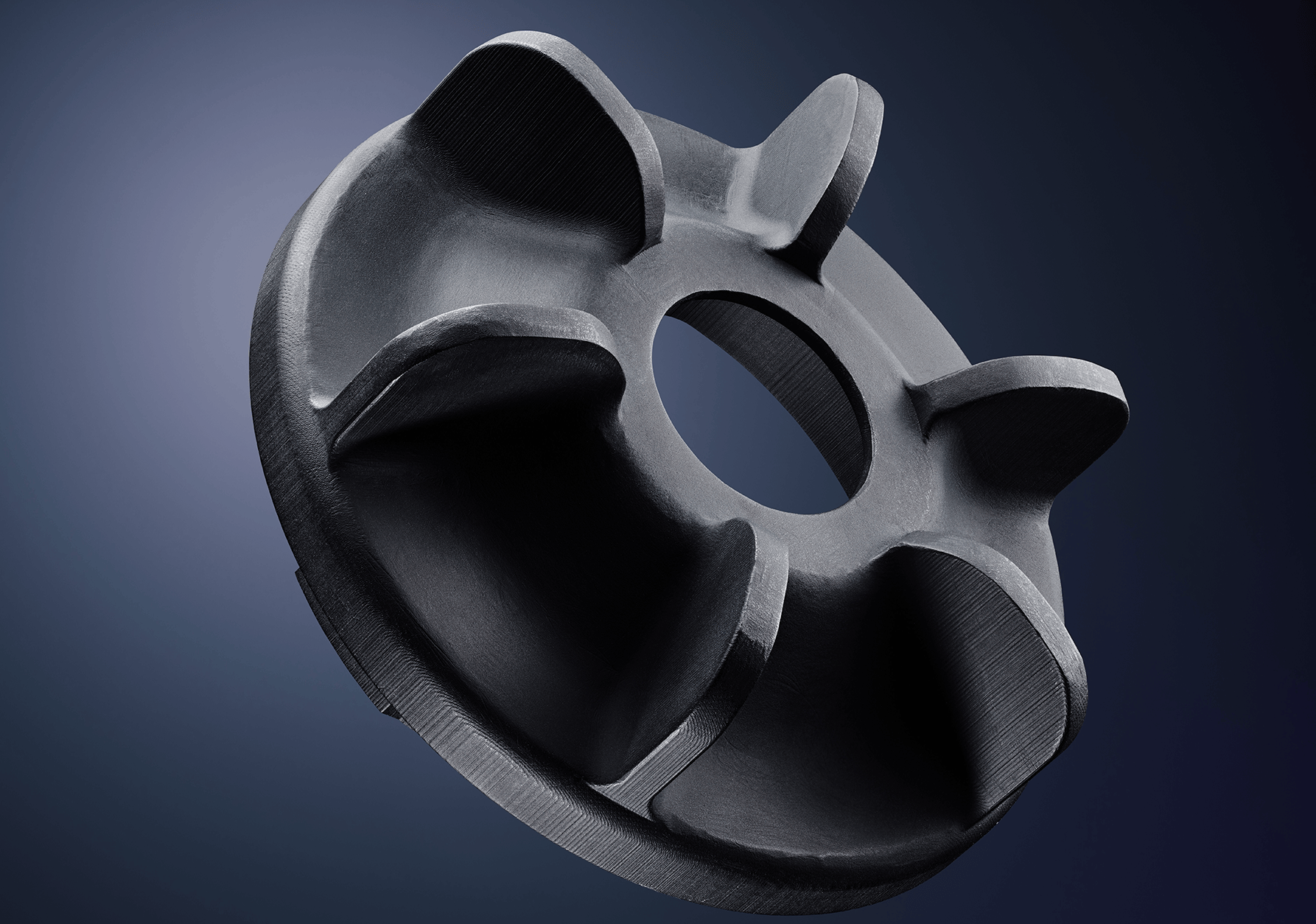

The lightweight strength and rigidity provided by structural foam molding make it ideal for large, flat, and thin-walled components across a broad range of industries. It allows downgauging and weight reduction without compromising performance.

Here are some of the main applications for structural foam injection molding:

Typical structural foam molded parts range in thickness from 4 mm to 10 mm. We can make it thicker, but usually increase the strength by adding ribs to get more ideal strength and effect, while saving material and cost.

Yes, we can. generally foam molding plastic parts don’t have a very good appearance. Painting the outer surface is one of the common methods. We can paint plastic parts made of most materials. Visit our post-molding operations service help you learn more other secondary molding process.