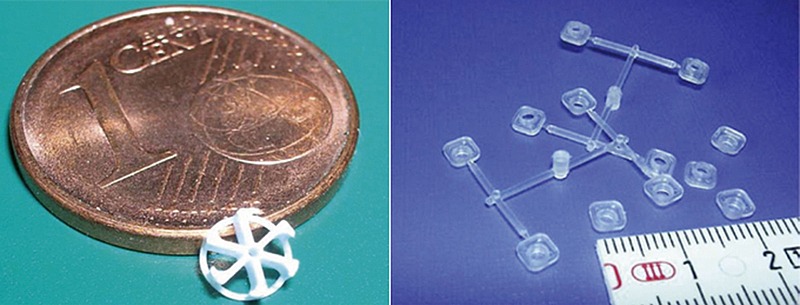

A Brief Talk on Micro Molding

Micro molding is a special injection molding process used to produce very small plastic parts.

READ

MORE

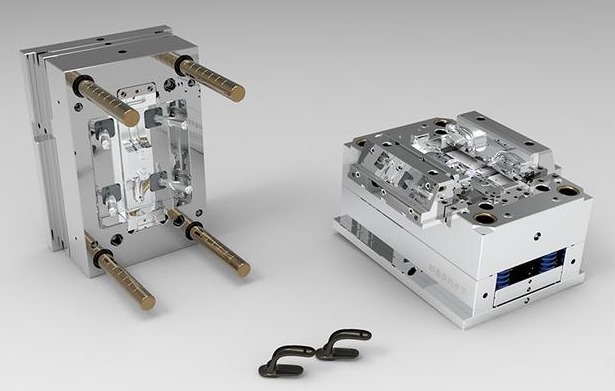

2025 The Most Comprehensive Injection Mold Design Guideline

The injection molding tooling is a crucial tool for producing plastic products, as its quality directly determines the product's quality. It holds a pivotal position in the production processes of plastic processing enterprises.

READ

MORE

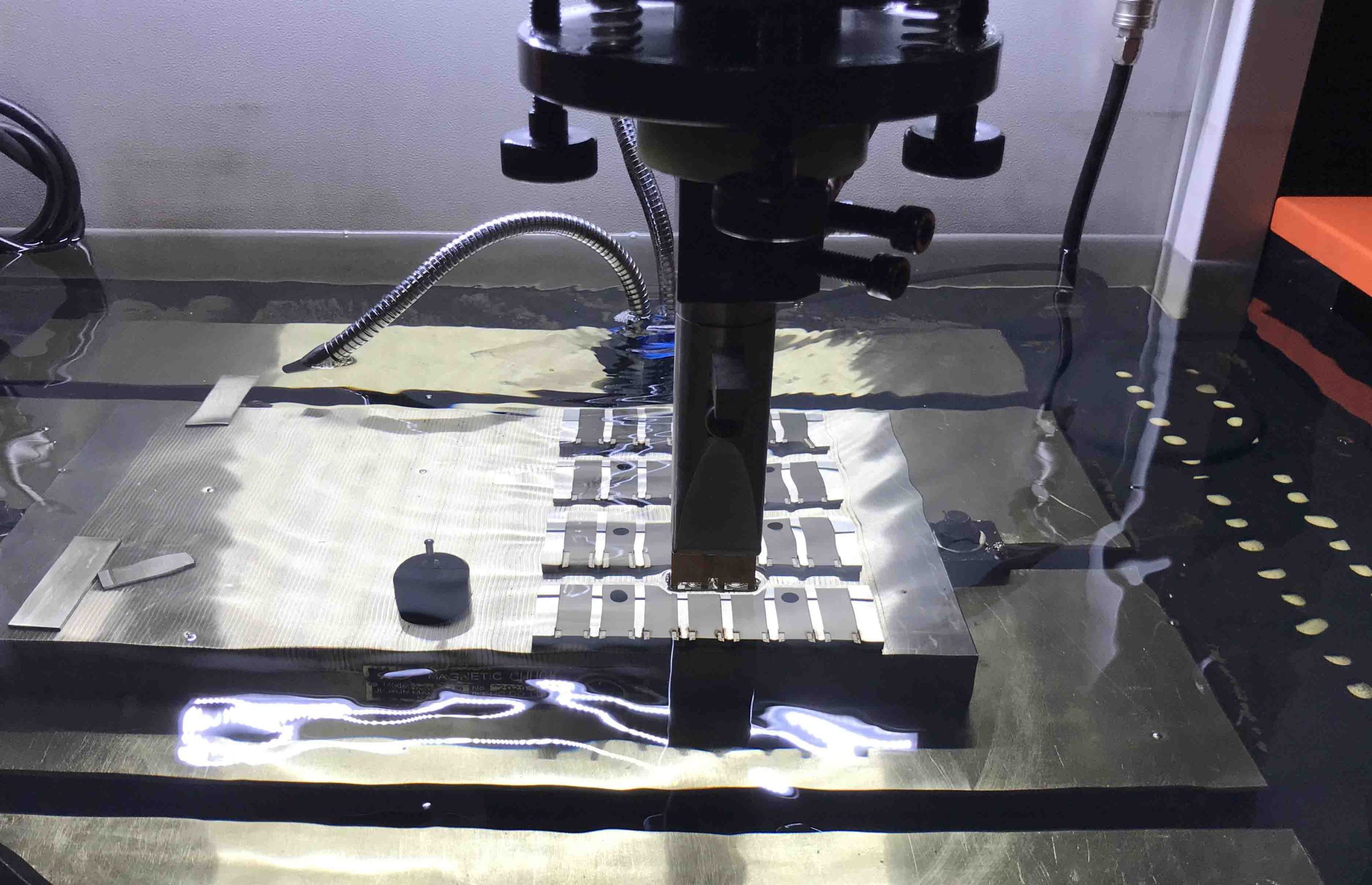

What is Electrical Discharge Machining ( 2025 Detailed explain)

With its unique advantages and wide range of applications, Electrical Discharge Machining has become an indispensable part of injection mold, automobile, aerospace manufacturing.

READ

MORE

Ultrasonic Welding Ultimate Guideline

Ultrasonic welding is a solid state joining process that uses high-frequency ultrasonic vibration friction to achieve bonding.

READ

MORE

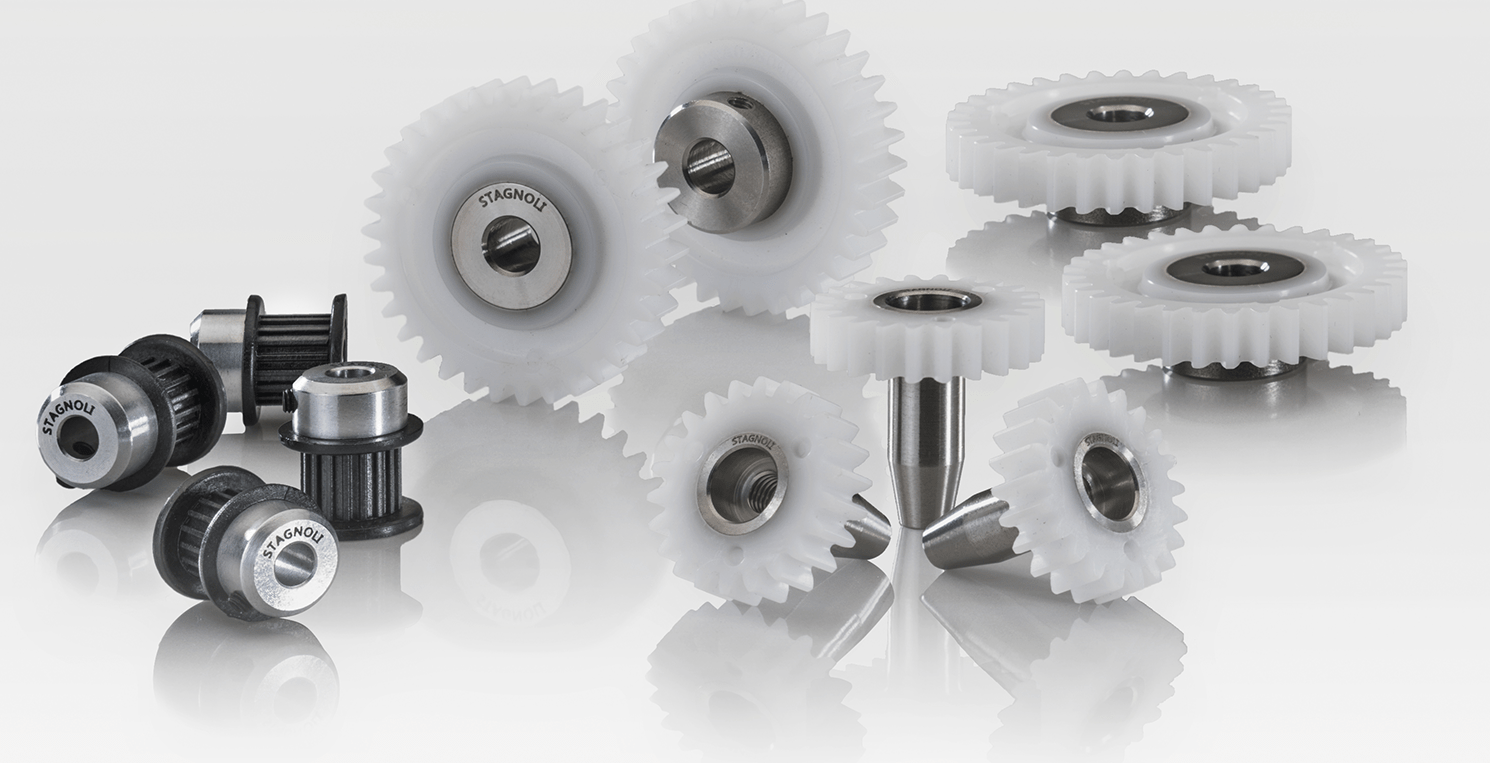

Insert Molding Comprehensive Design Guideline – Everything You Need to Know

Insert molding is a subset of injection molding that is becoming increasingly popular due to its high durability, reliability, and economy.

READ

MORE

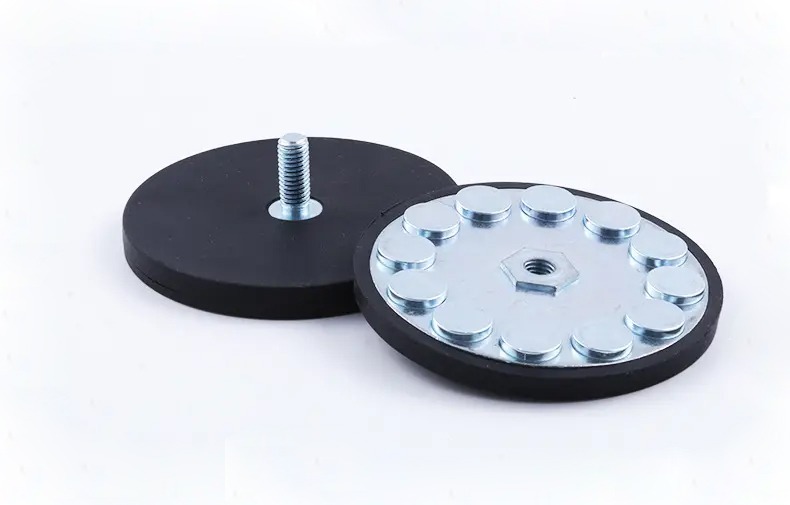

Overmolding Magnets : Definition, Advantages, Application

Overmolding magnets not only enhances the durability and stability of magnets, but also endows them with more functionality and design flexibility.

READ

MORE

What is Screen Printing? How It Works, Benefits & Applications

Screen printing, also known as Silk screen printing, is a very old and practical printing technology. It creates a pattern or text by using a screen plate to transfer ink or other coatings to a substrate.

READ

MORE

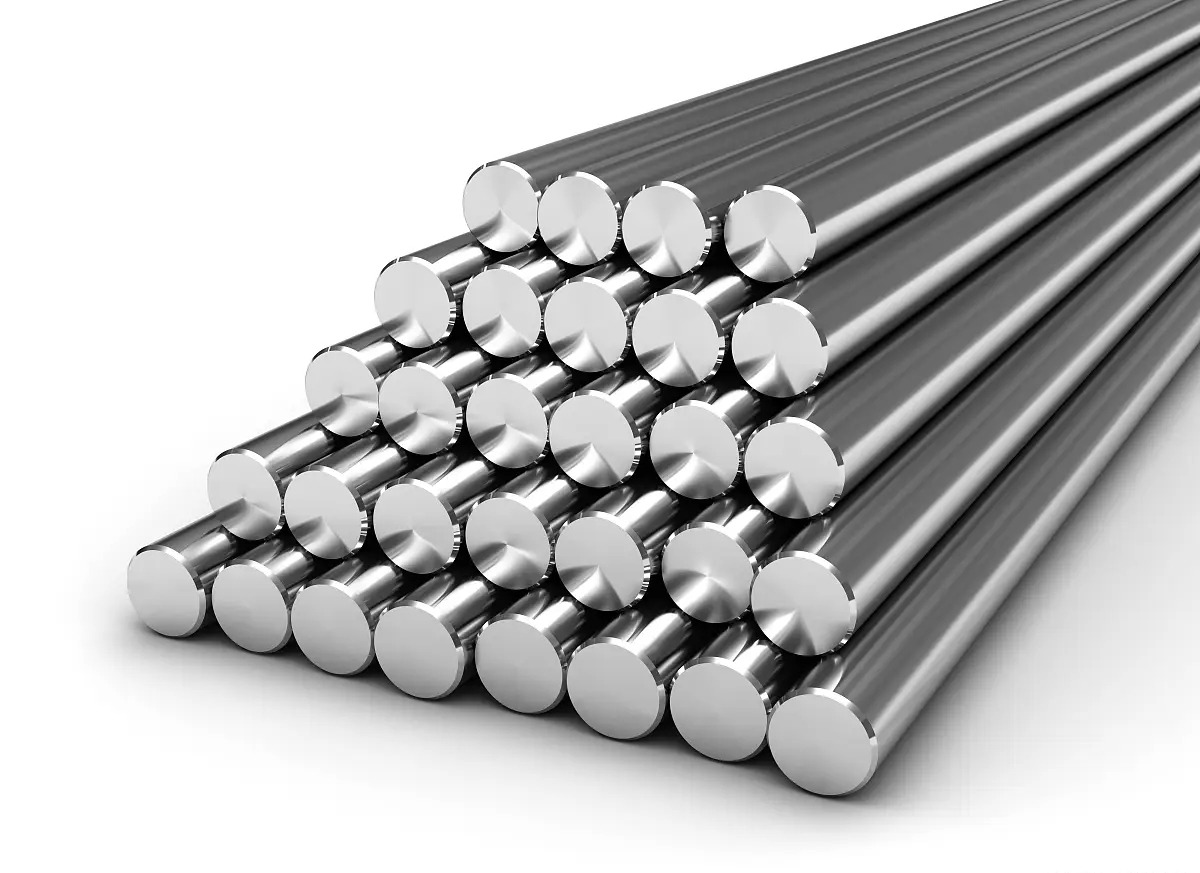

Carbon Steel Types, Characteristics, Applications

Carbon steel is used to indicate the steel with carbon as the main alloying element.

READ

MORE

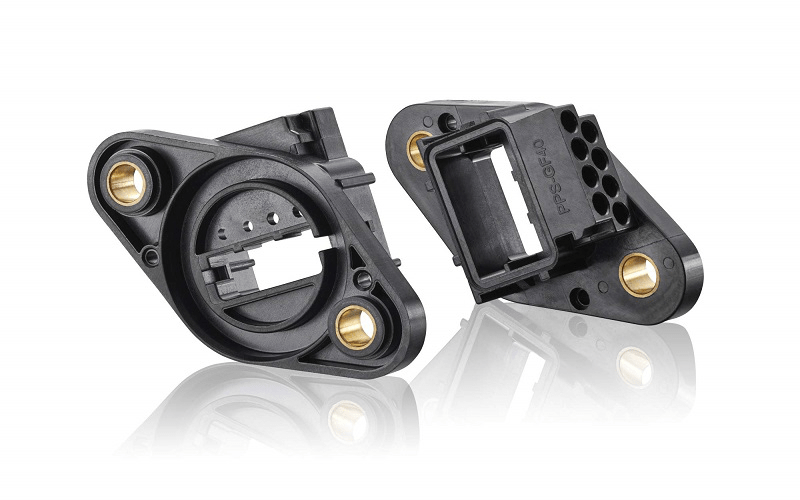

A Comprehensive Guideline to PPS Plastic: Everything You Need to Know

Polyphenylene sulfide (PPS) has excellent heat resistance, chemical resistance, mechanical strength and electrical properties.

READ

MORE

A Comprehensive Guideline to Nylon Plastics: Everything You Need to Know

Nylon offers high strength, stiffness and dimensional stability, as well as elasticity and chemical resistance.

READ

MORE

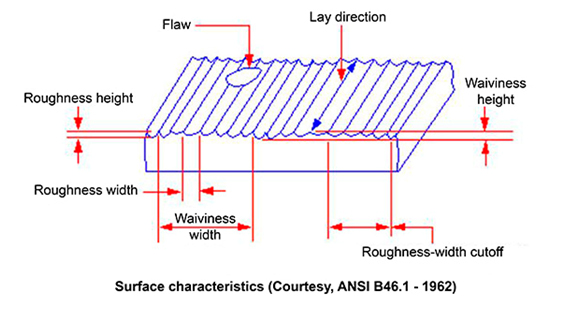

Surface Roughness Ultimate Guideline: All You Need to Know

Surface roughness is an extremely important technical index. In many industrial fields, properly controlling it is key to control quality.

READ

MORE

ABS Injection Molding Comprehensive Guideline

ABS is an amorphous terpolymer composed of three compounds: acrylonitrile, butadiene and styrene. it have good toughness and impact resistance (even at low temperatures), stiffness and processability.

READ

MORE