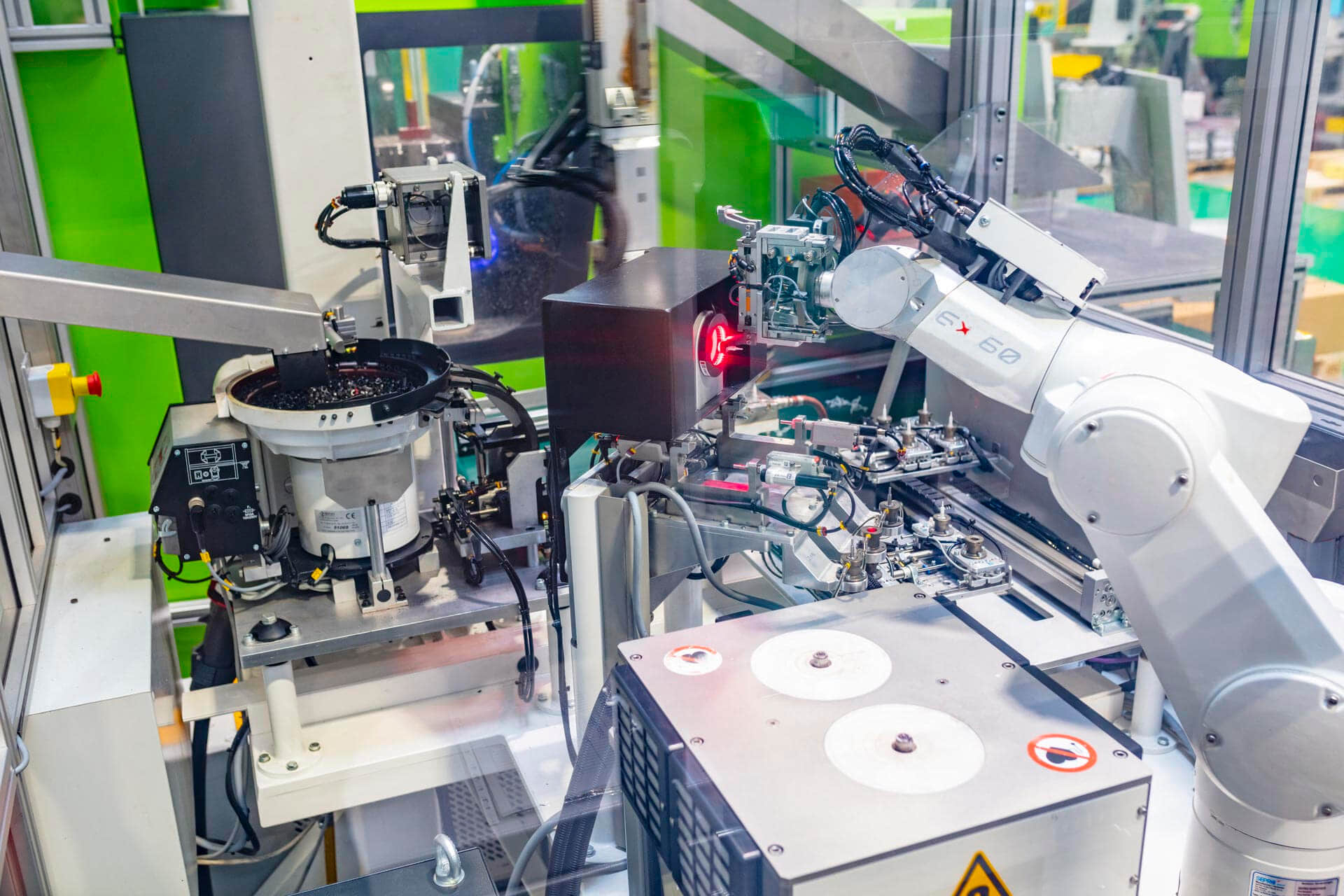

The most complicated supporting injection molding automatic production equipment we developed is for a small part with ABS insert molding of 3 magnets inserts. The part size is 40mm*35mm*20mm, because the inserts are small and placed in two directions, which greatly increases the difficulty of automation. But because the order volume exceeds one million per year, it is necessary to use automation to improve efficiency. The automation took 20 days to make and cost $25,000.

Generally, this type of automation is more complicated, with higher precision and higher cost. For this kind of product automation, we generally negotiate with customers to jointly invest or return it to customers after a certain amount is produced.

No, regular fixtures are relatively simple. According to production needs, we make them ourselves without any charge to the customer.

No, for some very complicated fixtures, like jig, end-of-arm toolings, we choose to make them together with our partners, they are more professional than us.

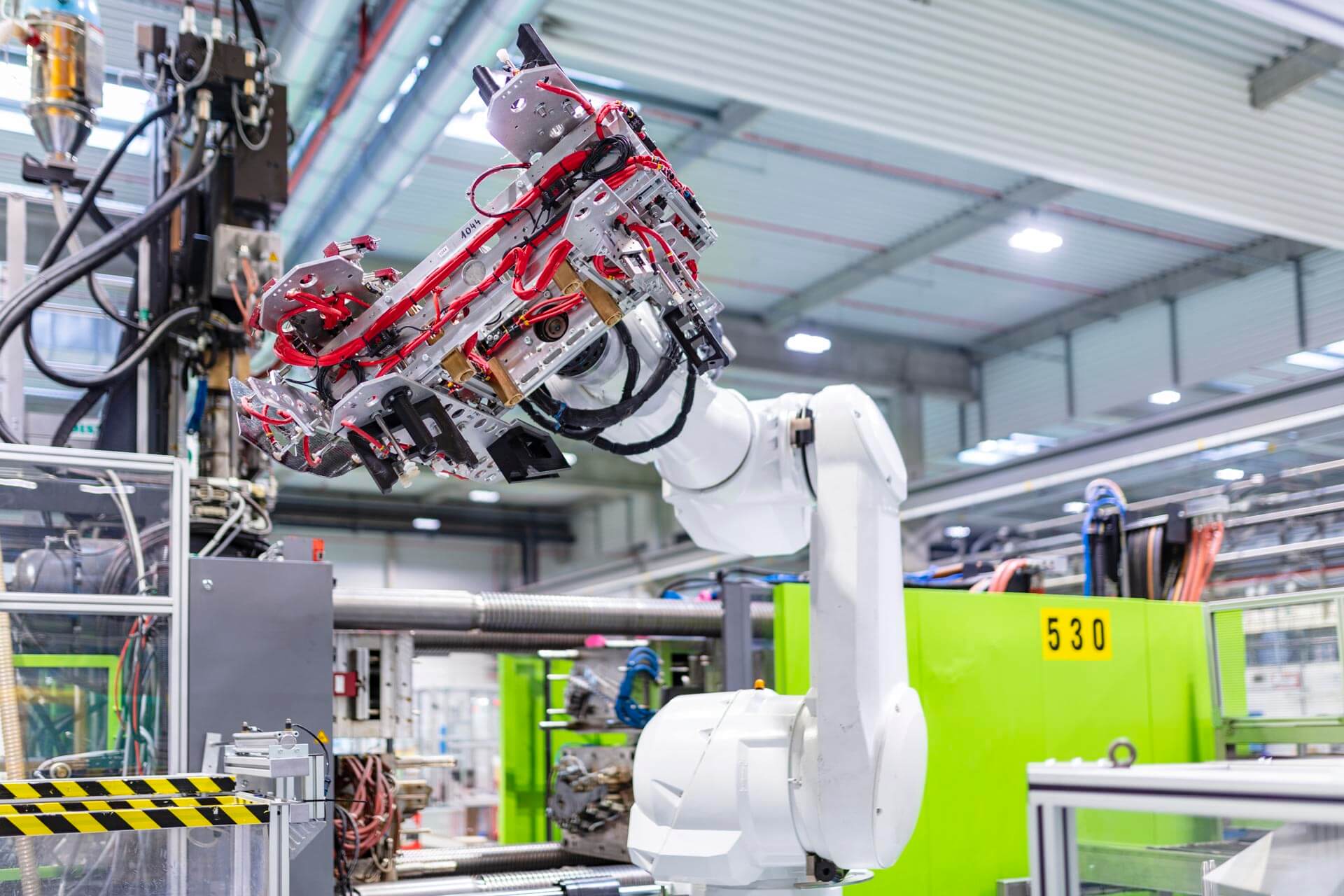

End-of-arm tooling (EOAT) refers to the tool or fixture that is mounted on the end of a robot arm. EOAT allows the robot to perform specialized tasks by holding and operating different types of tools.

Depending on the complexity and the realized functions, simple jig can be completed within one day.