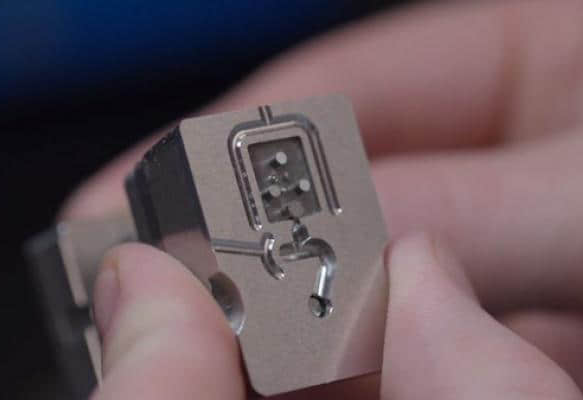

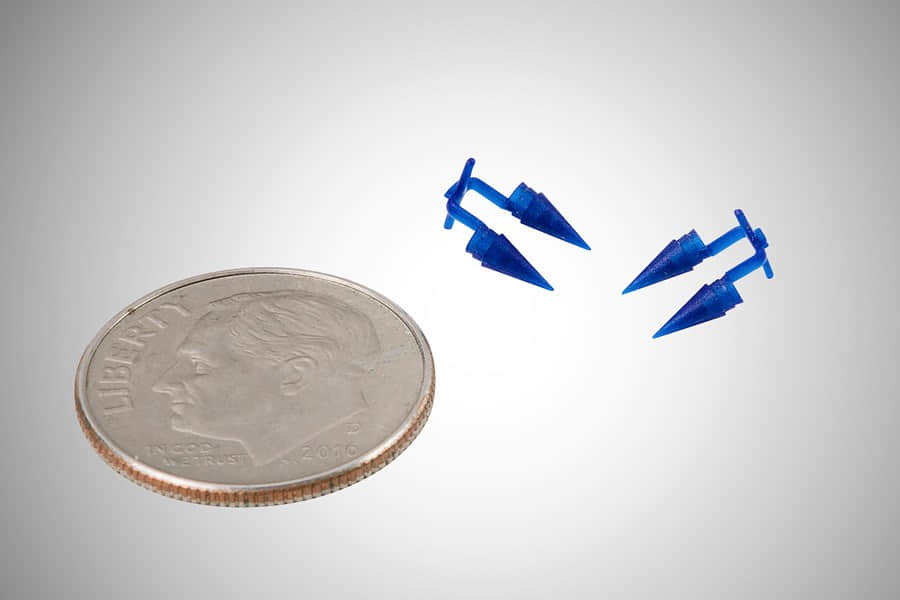

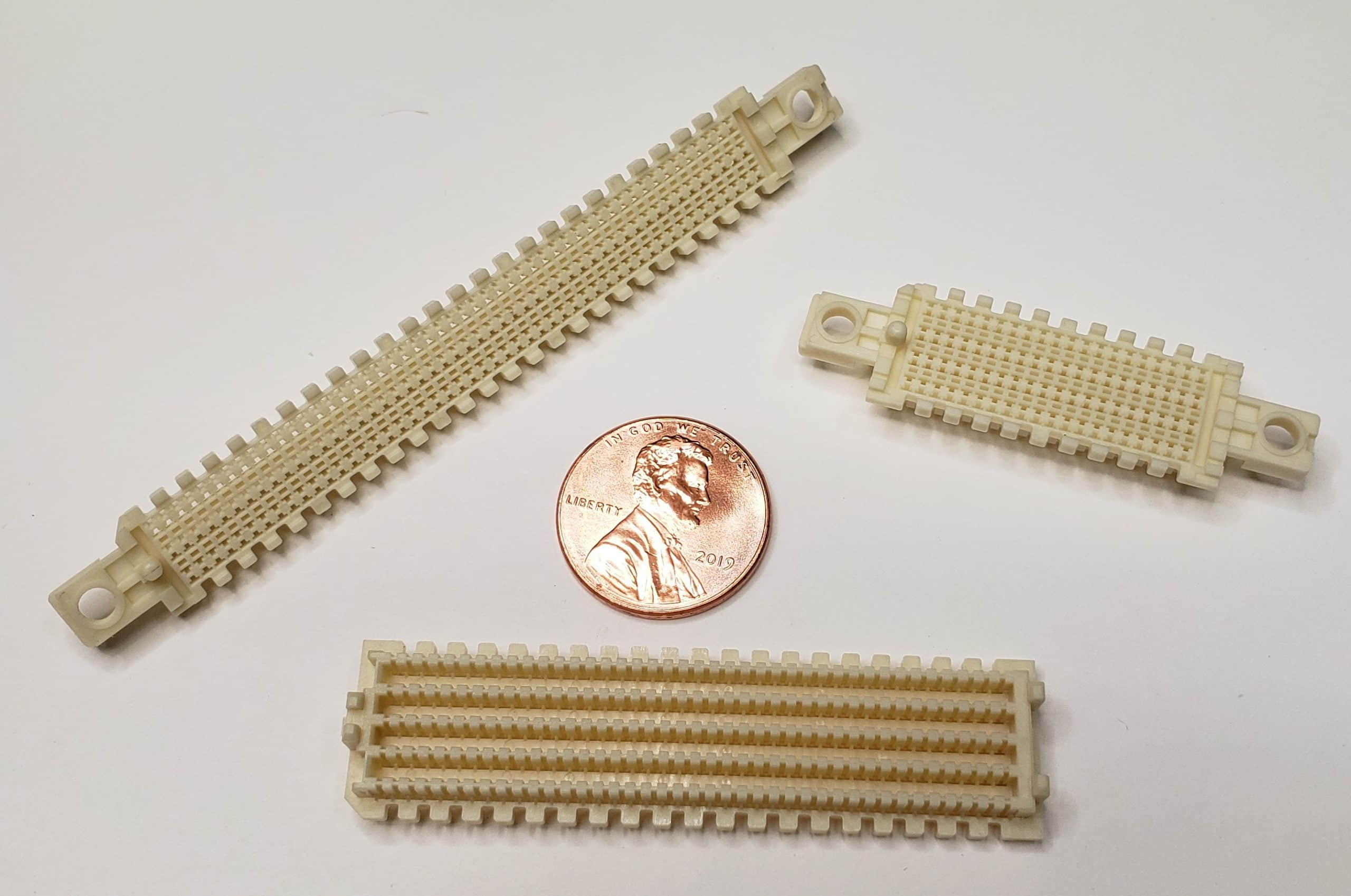

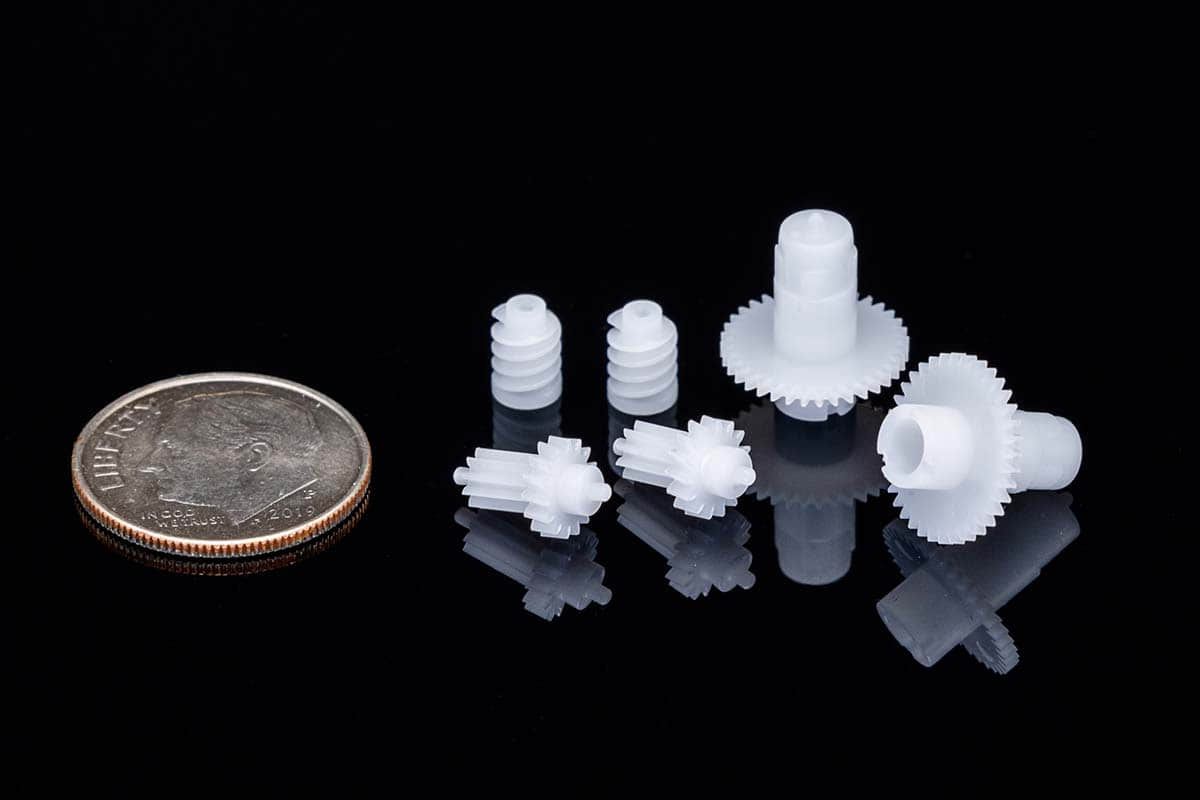

Micro molding, also know micromolding, micro injection modling, it is an specialized injection molding process capable of producing tiny plastic parts with high precision, tight tolerances, and excellent repeatability. It is used to manufacture extremely small components weighing less than 1 gram and measuring less than 3 millimeter in size. Micro molding requires specialized equipment like micro injection molding machines and is commonly used for medical devices, electronics, and other applications where small size, precision, and lightweight parts are critical.

Micro plastic part size is primarily limited by gate size. Injection weight limits range from 0.1 grams to several grams, and part sizes usually range from 3-4mm. If you want to make micro plastic parts, please contact our engineers and we will provide targeted solutions.

Most conventional thermoplastics can be micro molding, but typically without the addition of glass fiber. Because micro molding gate is very small, the glass fiber may impede the flow of plastic and affect molding.

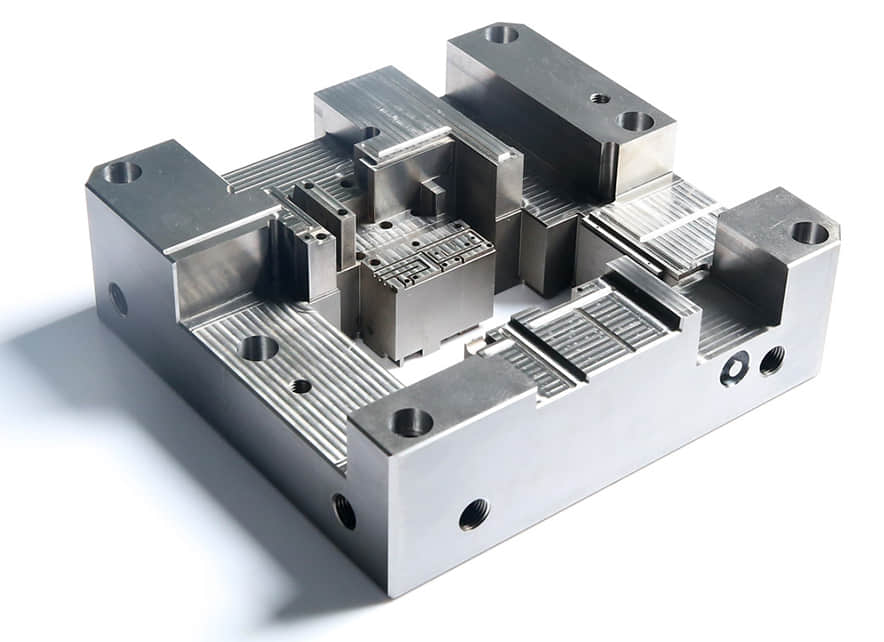

Depending on the order quantity, quenched and hardened steel can be used to make the mold. This can ensure that the life of the micro-molding mold is longer than that of conventional molds. You should choose different grades of mold materials according to the actual situation to meet your mold life.

Because micro molding can save materials, meet the demand for lightweighting, and also save costs, it is favored by many industries, including automotive, aerospace, medical equipment, etc.

Generally speaking, micro-molded plastic parts require less raw materials and faster production cycles. Both the mold cost and the product price should be lower than the cost of conventional injection molding. However, if a specific plastic part has tight tolerance dimensional requirements and other requirements, this must be determined based on actual conditions.