Material

Image

Description

Applications

More Infos

PP

Polypropylene, referred to as PP, is a colorless, odorless, non-toxic, translucent granular plastic. It has high toughness, fatigue resistance and chemical corrosion resistance, but is susceptible to ultraviolet radiation and is flammable.

Movable hinges, buckets, packaging boxes, lunch boxes, bottle caps, toys, etc.

ABS

ABS combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene, providing excellent strength, toughness, temperature resistance, chemical resistance, low shrinkage, high dimensional stability and low price.

Electrical and electronic product casings such as power tools, computers, mobile phone parts, automotive exterior and interior parts, medical equipment, etc.

PC

Polycarbonate (PC) is a highly transparent plastic with excellent optical properties, good impact resistance, high rigidity and hardness, low shrinkage, good dimensional stability, heat resistance and UV resistance. It is commonly used as outdoor protective shells wait.

Lenses, mobile casings, computer casings, medical equipment, lamp casings, etc.

SAN

Styrene acrylonitrile resin, often abbreviated as SAN, is a copolymer of styrene and acrylonitrile with good transparency and chemical resistance, high stiffness and good dimensional stability. Because of its advantages such as resistance to grease and stress cracking, it is commonly used in kitchen supplies, cosmetic packaging, consumer goods and other industries.

Water cups, kitchen supplies, cosmetic packaging, auto parts, etc.

PS

Polystyrene is non-toxic and odorless, and general-purpose polystyrene (GPPS) and high-impact polystyrene (HIPS) are probably the most commonly used PS resins in injection molding. GPPS is transparent and brittle, while HIPS is opaque, tough and not brittle.

Knives, forks, spoons, cups and other consumer goods

PC/ABS

PC/ABS is an engineering thermoplastic mixed with PC and ABS. Its properties depend on the ratio of PC to ABS in the blend. Improved mechanical properties compared to ABS or PC and lower cost than PC.

Automotive, electronics & electrical products, keyboard, consumer goods etc.

PE

PE is divided into low density polyethylene (LDPE) and high density polyethylene (HDPE). LDPE is manufactured at high pressure and temperature, while HDPE is manufactured at relatively low pressure and low temperature. All have characteristics such as toughness, impact resistance, chemical resistance, high shrinkage, and low dimensional stability.

Plastic barrels, drinking water barrels, water pipes, bottle caps, etc.

Nylon/Glass fiber Filled Nylon

Nylon is an engineering plastic with excellent load-bearing and wear resistance, high rigidity, high strength, good heat resistance and chemical resistance. Nylon 6 is one of the most widely used injection molding plastics in the polyamide family. Polyamide is often blended with glass fibers (usually in proportions ranging from 10-50%) to obtain additional thermal stability and minimal shrinkage.

Conveyor belts, automotive parts, cable ties, etc.

PBT

PBT (polybutylene terephthalate) is a semi-crystalline thermoplastic engineering plastic with excellent toughness, stiffness, impact strength, high strength, chemical resistance and flame retardancy.

Commonly used in electronic, electrical and automotive industries

PMMA (Acrylic)

PMMA (acrylic) is a highly transparent material with excellent optical properties and is considered an alternative to glass. It has good weather resistance, high strength and stiffness, and is scratch-resistant, but has low chemical resistance.

Car headlight covers, lenses, transparent shells, microscope lenses, etc.

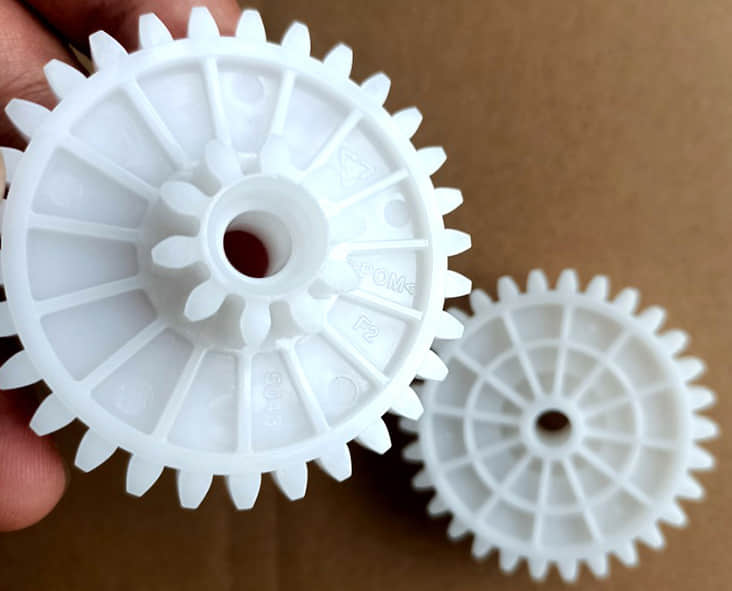

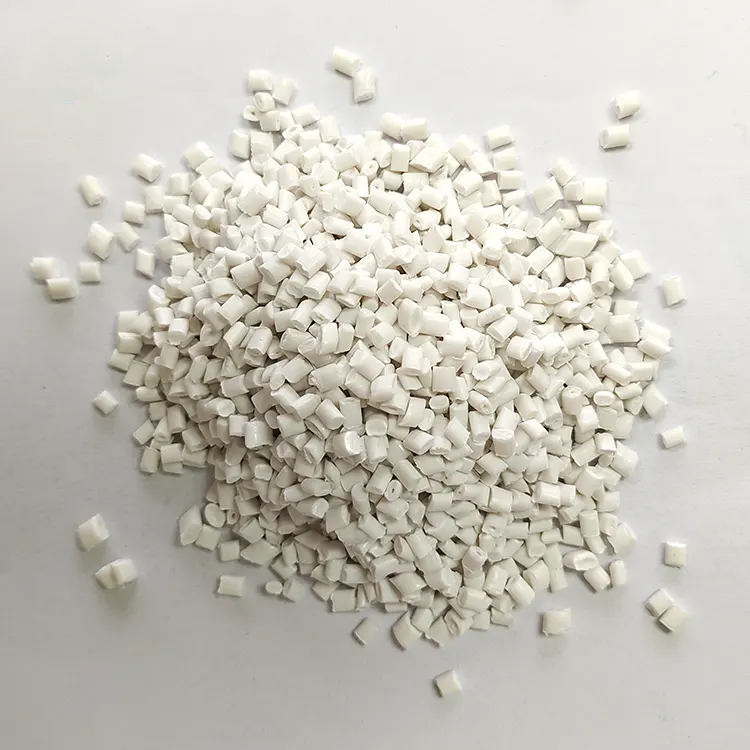

POM

Polyoxymethylene (POM), commonly known as acetal, also known as polyacetal and polyoxymethylene, is a high-performance engineering thermoplastic that is opaque white particles in its natural state. It has high strength, high hardness, toughness, high chemical resistance, excellent dimensional stability, and excellent fatigue resistance. Commonly used in precision parts that require low friction, especially in automotive parts.

Gears, pumps and pump impellers, conveyor chains, and blower blades, electrical switch components, knobs, handles, fasteners, automotive parts, etc.

PET

Polyethylene terephthalate (PET) is a thermoplastic polymer that is lightweight, strong, impact-resistant, chemical-resistant, has low moisture absorption, and has low thermal expansion.

Plastic bottles, trays, storage boxes, etc.

PVC

Polyvinyl chloride (PVC) is a high-strength white thermoplastic material that is available in powder or granular form and is flame retardant. It is extremely corrosive to injection molds, so the molds need to be made of unique corrosion-resistant materials such as stainless steel or chrome plating.

Wastewater pipes, wire and cable insulation, industrial parts,Medical device parts, etc.

TPE

Thermoplastic elastomers (TPEs) are flexible, rubber-like thermoplastic copolymers that have excellent thermal properties and stability. Softness or hardness value is measured by Shore hardness tester.

Auto parts, consumer products, power tools, toys, etc.

PFA(PTFE)

PFA (perfluoroalkoxy) is a tough, flexible, high-performance fluoropolymer with excellent resistance to high temperature, humidity, chemical resistance, high dielectric insulation, low friction coefficient, and excellent stability.

Commonly used to make accessories and linings for corrosive parts such as valve linings, semiconductor baskets, tank linings, nozzles, insulator brushes, pumps and electrical insulators, etc.

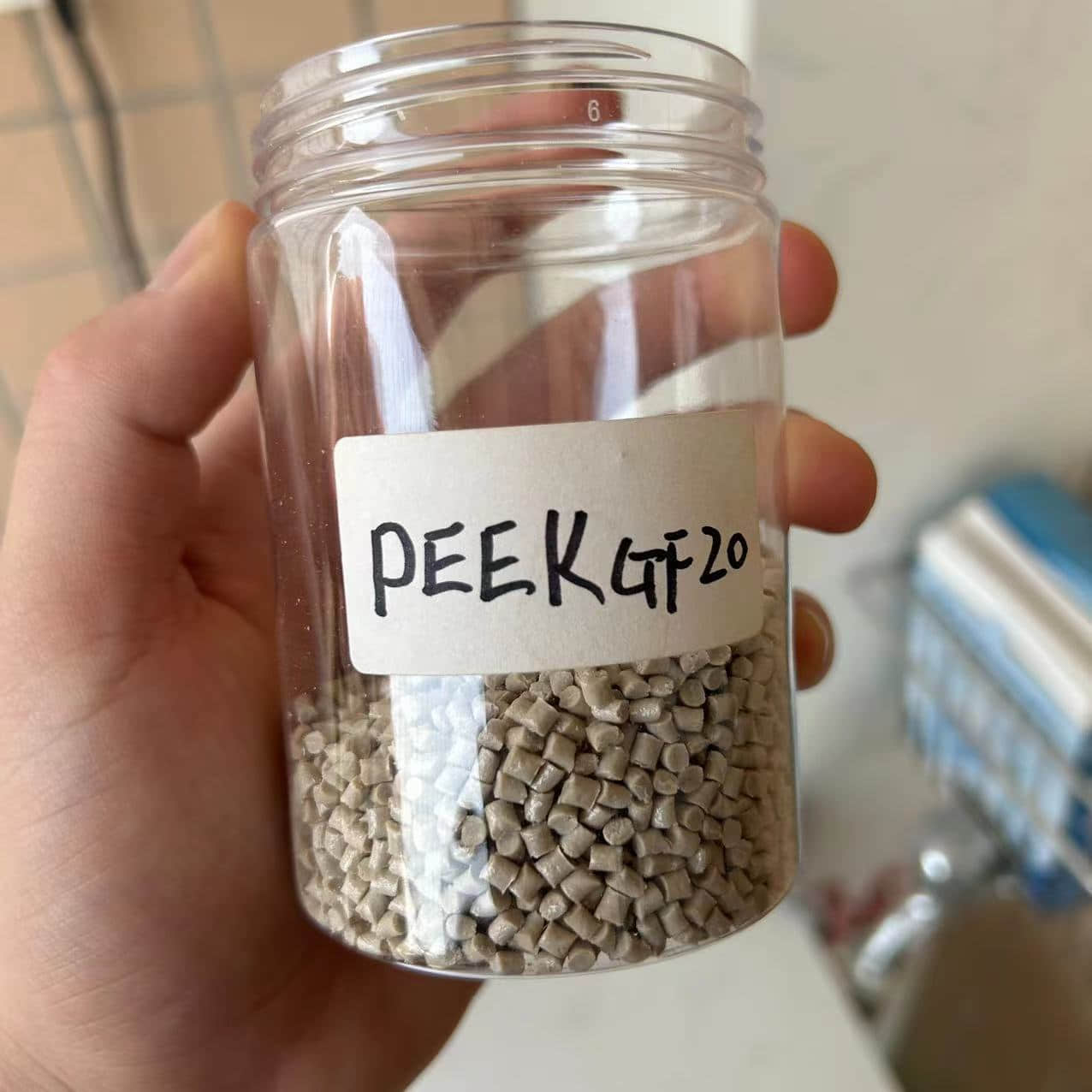

PEEK

Polyetheretherketone (PEEK) is a colorless organic semi-crystalline thermoplastic polymer with high temperature resistance, flame retardancy, high performance, chemical corrosion resistance, excellent mechanical strength, dimensional stability, self-lubrication and other characteristics.

Bearings, piston parts, pumps, automotive, aerospace components,medical implants etc.

PPS

PPS (polyphenylene sulfide) is a high temperature thermoplastic polymer with characteristics such as flame retardant, high temperature resistance, wear resistance, chemical resistance, and high dimensional stability. PPS is often used as a low-cost alternative to PEEK in low to moderate temperatures

Widely used in industrial parts such as pumps, valves, semiconductor machinery parts, air conditioning parts and scientific instrument parts.

LCP

LCP polymer is a primarily aromatic polyester with excellent mechanical strength, temperature and flame retardancy, chemical resistance, and high dimensional stability. LCP has excellent flow properties, which makes it particularly suitable for making thin wall parts.

Electrical connectors, surgical instruments

PPA

Polyphthalamide (PPA) is a high-hardness, high-strength, chemical-resistant, high-performance resin in the nylon family that performs better than standard polyamides. It has excellent thermal, mechanical and physical properties, and is hygroscopic, opaque and semi-crystalline. Continuous use temperature range is 120 ℃ to 185 ℃ (248 ℉ to 365 ℉). Heat distortion temperature (HDT) up to 310 ℃ (590 ℉).

Auto parts, fuel line connector, coolant pump

PEI

Polyetherimide (PEI) is an amorphous high temperature engineering plastic with good hydrolytic stability, high dimensional stability, high heat resistance, excellent electrical properties, inherent UV resistance, flame retardancy and Low smoke production. Its cost is relatively low compared to other high temperature materials.

Aircraft interior, Medical device parts,electrical connector, automotive, aerospace

PES

PES is a high temperature engineering thermoplastic that can withstand high temperatures for long periods of time. PES has good chemical compatibility and resistance to hydrolysis, and has good resistance to radiation, X-rays, beta rays and gamma rays, making it an ideal material for applications requiring good dimensional stability.

Pump housing, valve piston, connector, filtration membrane, medical devices

PPSU

PPSU (polyphenylsulfone) is an amorphous thermoplastic material that is highly impact-resistant, chemically resistant, and flame retardant and can be used continuously at temperatures up to 300 ℉ (149 ℃) without affecting performance. Compared with polysulfone (PSU) and polyetherimide (PEI), it has superior toughness, better impact resistance and chemical resistance, and can withstand repeated unlimited steam sterilization and continuous exposure to moisture and at high temperatures, it can still absorb huge impacts without breaking.

Aircraft interior parts,bezels,medical instrument handles, medical instrument parts, sterilization trays.

PPO

Polyphenylene oxide (PPO) is an amorphous engineering thermoplastic with high heat resistance, dimensional stability, very low hygroscopicity, low thermal expansion, excellent impact strength, light weight and hydrolytic stability, and can be used in temperatures exceeding 220 ℉ continuous operation at the temperature.

Instrument casings and internal parts of electrical equipment, automotive parts, medical equipment.

TPU

Thermoplastic polyurethane (TPU) is a soft thermoplastic elastomer that can be injection molded and has excellent tensile strength, high elongation at break and good load-bearing capacity.

Automotive, wires and cables