Strong Mechanical Properties

Strong Mechanical Properties

High Dimension Stability

High Dimension Stability

Excellent Chemical Resistance

Excellent Chemical Resistance

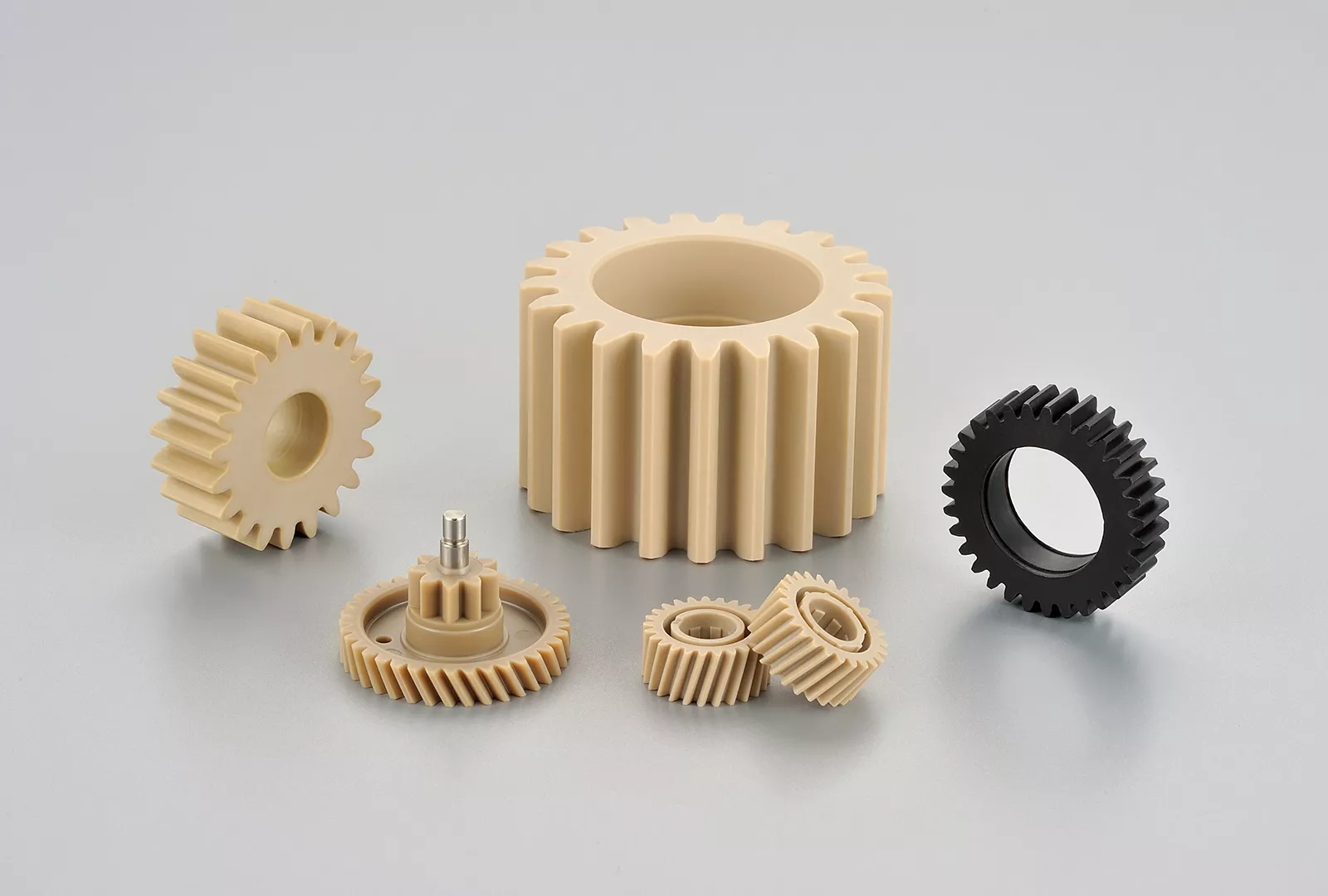

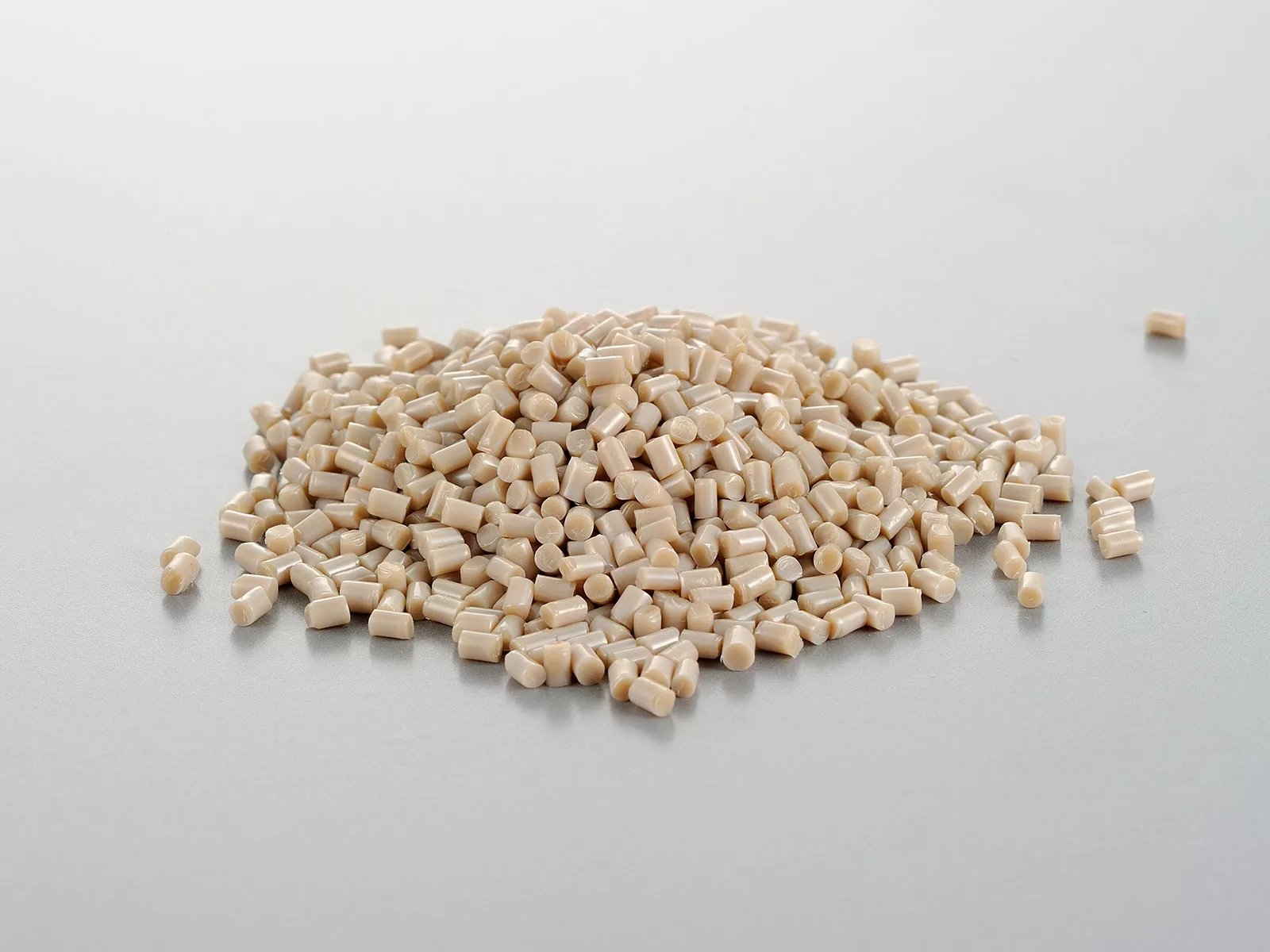

Common types of high temperature plastics include polyimides (PI), polyetheretherketone (PEEK), polyphenylene sulfide (PPS), liquid crystal polymers (LCP), Polyethersulfone (PES), Polyphenylsulfone (PPSU), Polyether Imide (PEI), Polysulfone (PSU), PolyEtherKetone-EtherKetoneKetone (PEKEKK), Polyetherketone (PEK), Polytetrafluoroethylene(PTFE), Perfluoroalkoxy Alkanes (PFA), Polyvinylidene Fluoride(PVDF), polysulfones.Key application areas are in aerospace, automotive, oil & gas, electronics and medical sectors.

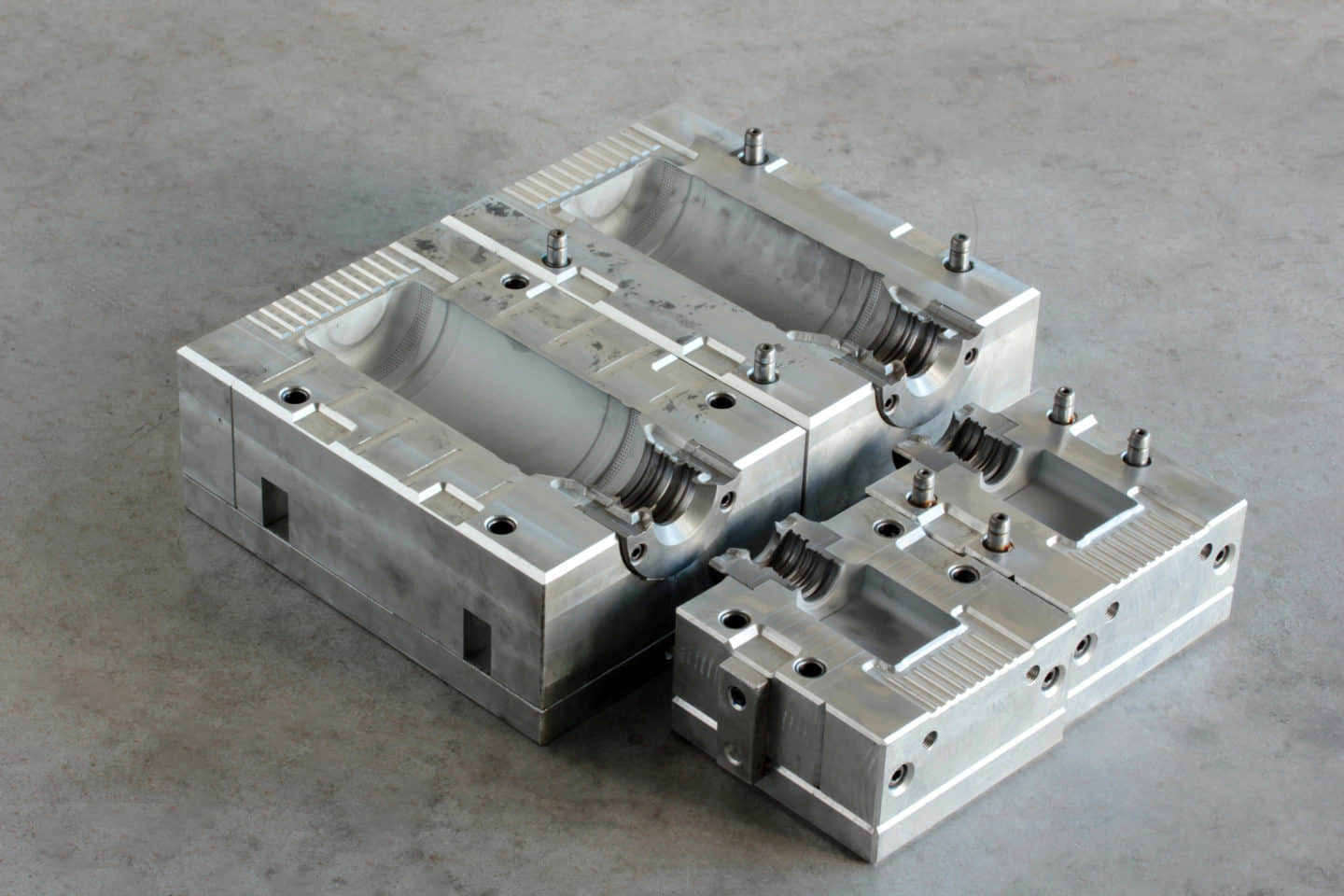

High Temperature Injection Molding is an injection molding technology characterized by the injection filling and cooling process when the mold temperature is usually higher than 150°C and the molding temperature is usually higher than 300°C.

Different from conventional injection molding, high-temperature injection molding uses high-temperature molds to reduce the viscosity of the molten plastic and enhance the fluidity of the material in the mold cavity. It can fill the mold cavity more fully and evenly, reduce flow lines and internal stress, and improve the appearance of molded parts. . These advantages make it particularly suitable for materials such as engineering plastics that are difficult to mold at conventional temperatures. For example, PEEK, PPS, PFA, PEI, PES, etc.

However, high-temperature injection molding also places higher requirements on mold materials and cooling systems. Care must be taken to prevent long-term high temperature damage to the mold.

High temperature plastics also called high-performance plastics, refer to a class of high performance thermoplastic polymers that can withstand and operate at elevated temperatures, typically in the range of 150°C to over 260°C. Some key characteristics of high temperature plastics:

Here are some of the main challenges associated with high temperature injection molding:

As a high temperature molding company with over 15 years of experience, we have extensive experience in this type of high performance plastics molding. Here are some of the key points we summarized. Careful selection of mold materials, mold deign, mold making, process optimization, tolerance control and mold flow analysis are key enablers for high temperature injection molding.

Here are some key factors for successful high temperature injection molding:

While high-temperature molding can achieve higher quality parts, the costs involved tend to be higher than conventional injection molding, both in terms of material costs and mold and injection molding costs. But compared with the cost of other materials, it still has advantages. High-temperature plastic parts have a long service life, are resistant to high temperatures and corrosion, are lightweight and durable. Therefore, in the long run, the cost is lower than products made of iron, aluminum and other materials.