In the plastics processing industry, injection molding is the most widely applied engineering process. Looking globally, American injection molding manufacturers have always been at the forefront of the industry.

Today, we will focus on the top 25 injection molding manufacturers in the United States. In terms of scale, technology or market influence, these 20 injection molding manufacturers set the benchmark in the industry. In addition to advanced molding equipment and technologies, their rich industry experience is also a key strength enabling them to provide high-quality injection molded products and services to customers.

Going forward, we will conduct a detailed analysis and introduction of these top 20 injection molding manufacturers, so that you can gain an in-depth understanding of the strengths and accomplishments these companies have achieved in the injection molding field.

Founded Year: 1946

Location: WI, United States

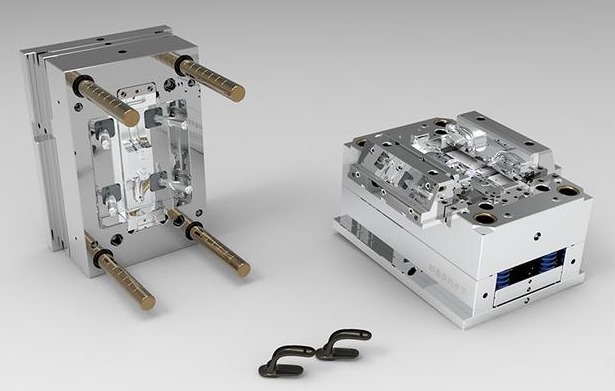

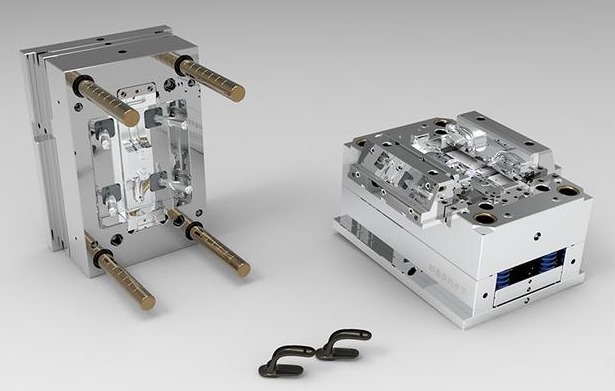

Business Type: Injection molding manufacturer, Design & Engineering, injection mold tooling manufacturing.

Offer Services: Engineering Support, Tooling Building, Injection Molding, Value-Added Services, Gas assisted molding, high temperature molding.

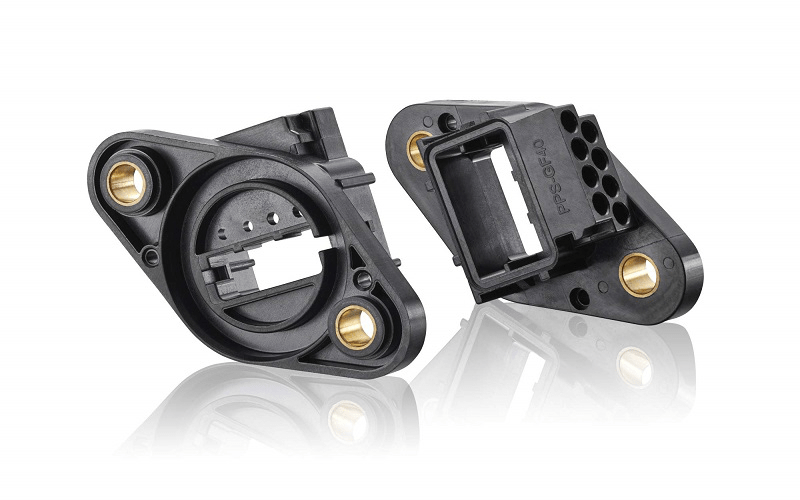

As a comprehensive plastic injection molding solutions provider for over 75 years, Kaysun Corporation has established itself as a trusted partner to leading industrial and consumer brands. Leveraging deep molding expertise and advanced injection machine, Kaysun delivers high-quality customized plastic components across various sectors. Their team of experienced engineers collaborates closely with clients to understand needs and provide tailored solutions for intricate medical devices, durable industrial parts or complex automotive components. Kaysun’s vertically integrated facility incorporates advanced injection molding technology and value-added processes, allowing strict quality oversight and consistent adherence to demanding standards set by medical, industrial, automotive and consumer customers. With a legacy of service excellence to Fortune 500 customers, Kaysun remains the solutions partner of choice for precision custom injection molded components.

Founded Year: 2005

Location: TX, United States

Business Type: Plastic injection molding manufacturer, plastic mold maker, plastic molding manufactuer.

Offer Services: Plastic injection molding, custom injection molding, prototype injection molding, Low-Volume Injection Molding, Prototyping, Tooling building, Precision molding

MSI Mold is a top provider of injection molding ,plastic mold, CNC machining services. Since its founding in 2005, MSI Mold has grown from an engineering consultancy into a fully integrated solution for plastic molding needs. Backed by advanced equipment and expertise, MSI Mold’s in-house engineers leverage the latest technologies to precisely manufacture both high-volume production parts and specialized prototypes. Through continuous innovation, meticulous quality standards, and close customer collaboration, MSI Mold has built a reputation over decades as a trusted and versatile partner for plastic injection molding solutions.

Founded Year: 2000

Location: Ningbo, China

Business Type: Custom injection molding manufacturer, Injection tooling manufacturer.

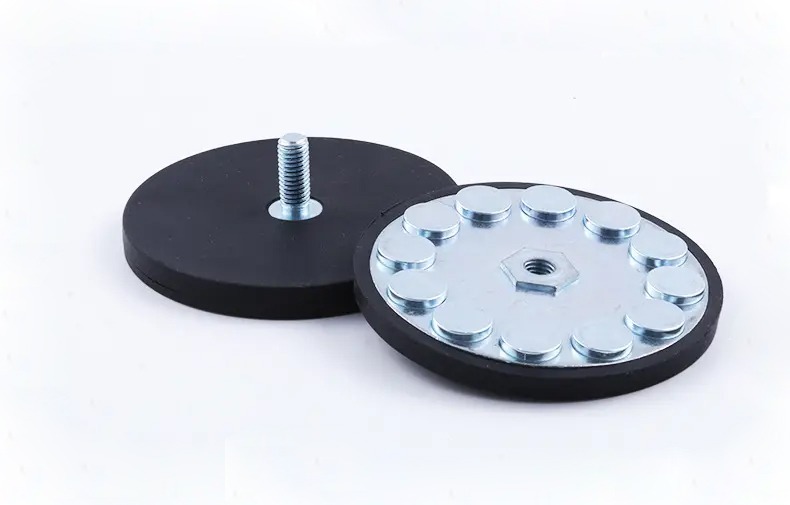

Offer Services: Custom Injection Molding, plastic mold making, mold design, mold machining, moldflow analysis, In-Mold Decorating & Labeling, Gas Assist Molding, Multi-Shot Molding, Secondary Operations, Design for Manufacturability (DFM), Prototyping, thin wall molding, high temperature molding, magnets injection molded and magntes overmolding.

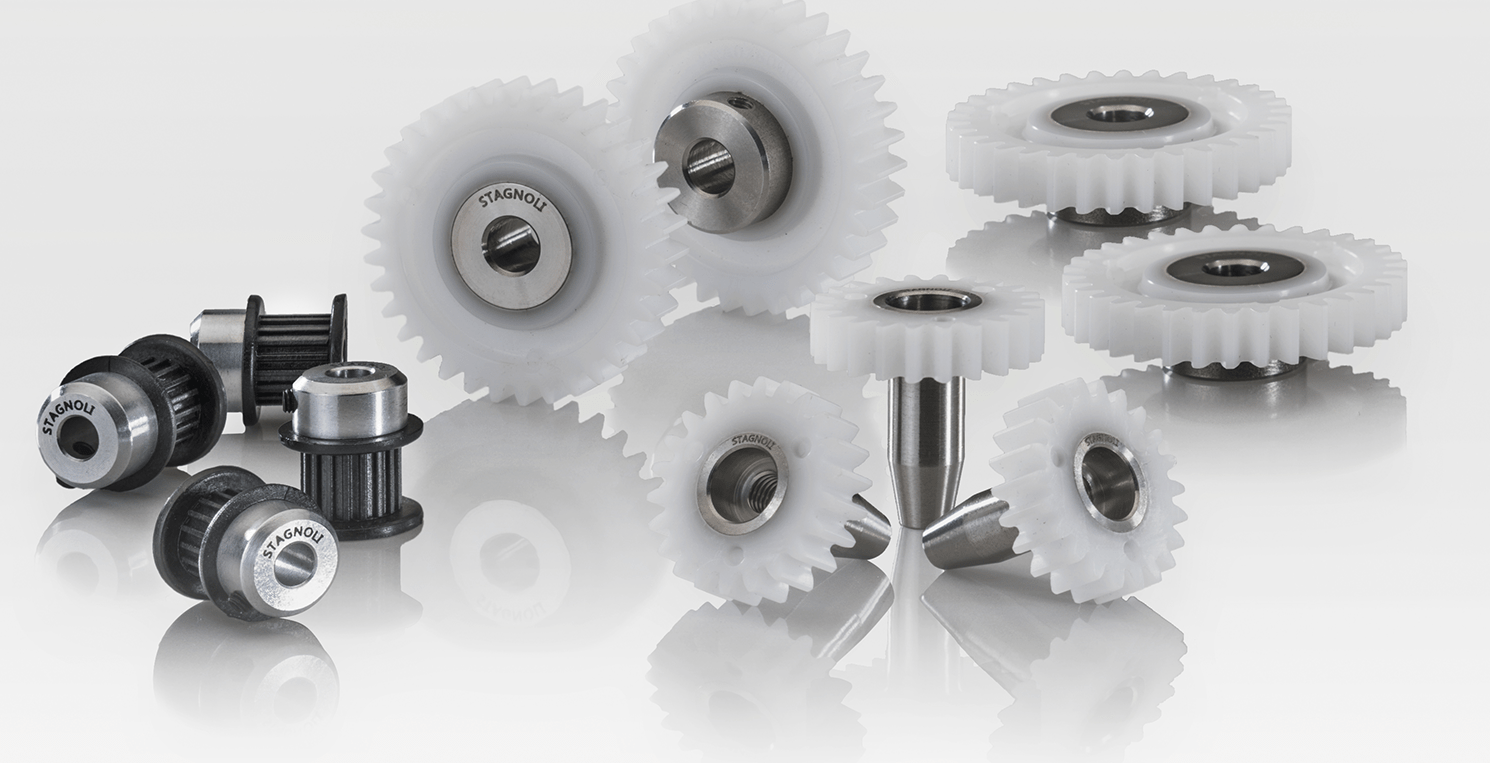

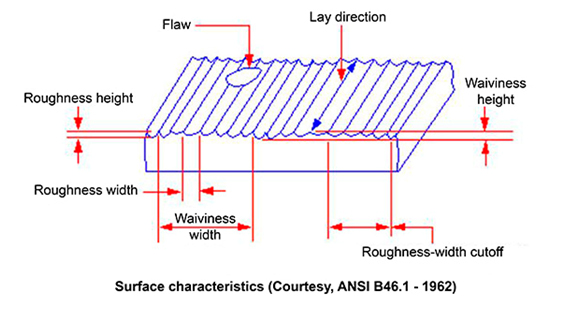

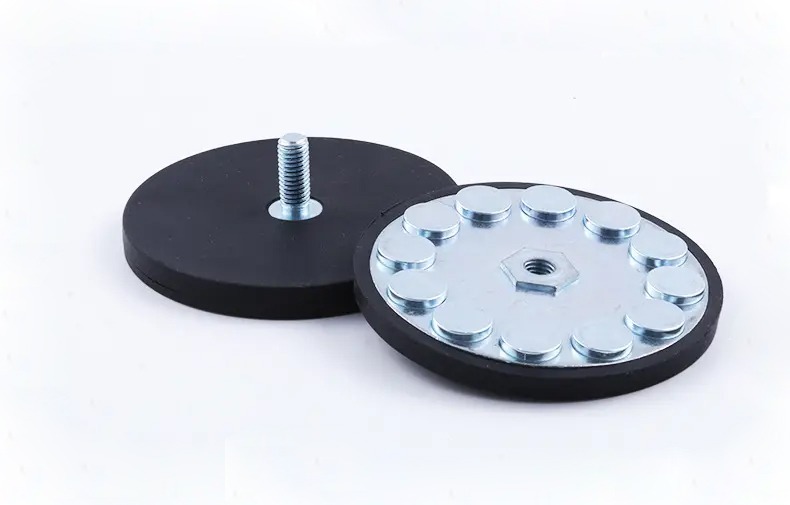

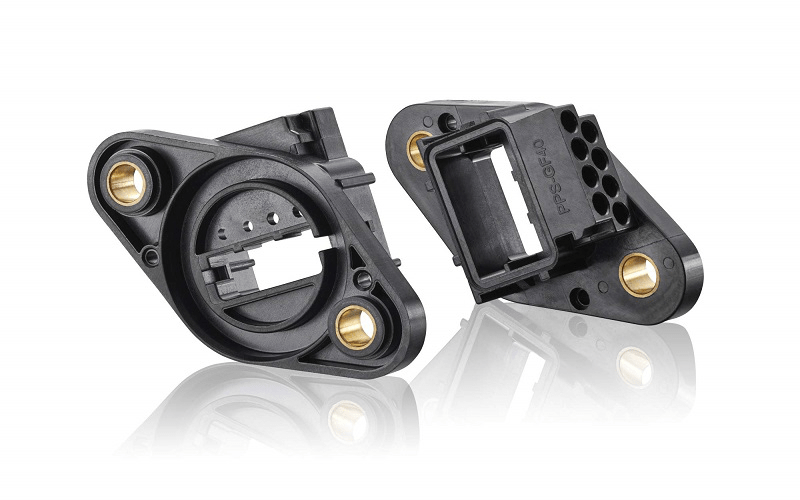

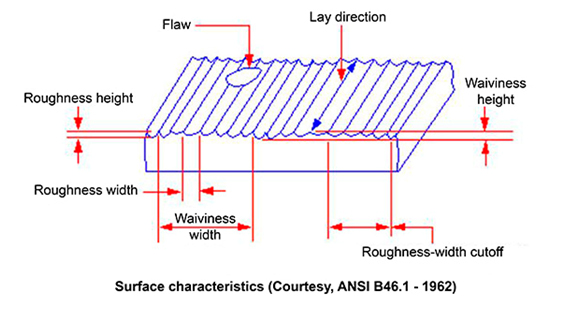

Attractive Plastics is a premier single plastic molding manufacturer renowned for its expertise in plastic injection molding and ability to craft complex plastic components. They distinguishes itself through its focus on high-temperature molding and thin-wall molding. Their expertise is not limited to standard molding techniques but also excels in custom high-performance plastic injection molding, providing tailored solutions that meet customer-specific demands. By leveraging the latest injection molding technology, they ensure each project, from prototyping to large-scale production is precisely and qualitatively executed. They are particularly good at insert molding magnets, overmolding Neodymium magnets, injection molded magnets, silicone rubber molding magnets, plastic integrated magnets, silicone encapsulated magnets, in this small field, they have more than 15 year experience. Attractive Plastics as a traditional injection molding factory, leverages its status as a top injection molding company to deliver high-performance plastic parts. They are the first source for 2023 Chinese plastic injection molding factories, providing competitive advantage through cost-effectiveness and industry-leading services. Attractive Plastics is a one stop molding company that establishes standards in the Chinese plastic molding sector, offering diverse services ranging from concept development to part design, plastic mold development, and sophisticated plastic injection molding production, while maintaining a commitment to various technological innovations.

Founded Year: 1964

Location: WI,United States

Business Type: Custom injection molding manufacturer, Injection Mold manufacturer, plastic injection molder.

Offer Services: Injection Molding, In-Mold Decorating & Labeling, Gas Assist Molding, Multi-Shot Molding, Liquid Silicone Rubber(LSR) Injection Molding, Stack Molds making, Secondary Operations, Tooling & Mold Building, Design for Manufacturability, Prototyping, Thin Wall Packaging.

EVCO Plastics is a leading global injection molded plastics contract manufacturer. Founded in 1964, EVCO has grown to 13 facilities worldwide specialized in custom plastic molding and mold making for automotive, electronics, medical and more.

Their engineers collaborate with customers on design and utilize advanced molding technologies to efficiently produce high-quality plastic parts. Beyond injection molding, EVCO offers decoration, assembly and logistics support.

Continuous innovation in manufacturing technologies and automation further enhances EVCO’s position as a premier provider of plastic injection molding and molding solutions, especially in medical devices.

Founded Year: 2005

Location: TX, United States

Business Type: Plastic injection molding manufacturer, scientific molding, medical plastic parts injection molding manufacuter.

Offer Services: Injection Molding, Mold Designing & Tooling, Plastic Injection Molding, Low-Volume Injection Molding, Prototyping, Tooling building, Precision molding, Secondary operations, Automotive injection molding, Medical device injection molding, ultrasonic welding, plating, screen printing.

All-Plastics is a leading provider of advanced manufacturing and project management services specializing in scientific plastic injection molding technologies and processes. Headquartered in Texas, the ISO 13485 certified company serves customers in pharmaceutical, medical, industrial, packaging and consumer sectors.

Leveraging expertise in precision plastic injection molding, All-Plastics ensures high quality and compliance standards for medical and pharmaceutical applications. An expert team of engineers and molding specialists collaborate to manufacture complex customized plastic components and medical devices.

Through utilization of automated systems and a fully integrated quality laboratory and tooling facility, All-Plastics handles sophisticated plastic injection molding projects. The company is committed to providing tailored injection molding solutions meeting the stringent demands of the Texas medical and pharmaceutical industries. their dedication to safety and education efforts have earned recognition from industry associations. Overall, All-Plastics positions itself as a leader in scientific plastic injection molding, delivering high quality, compliant products and unmatched service to customers across Texas and beyond.

Founded Year: 1986

Location: FL, United States

Business Type: Injection molding manufacturer, plastic parts design and engineering.

Offer Services: Injection Molding, Mold Designing & Tooling, Plastic Injection Molding, Clean Room Molding & Assembly, Post Molding Operations, Low-Volume Injection Molding, LSR Injection Molding. Micro molding, screen printing, silicone rubber molding.

Seaway Plastics is a leading plastic injection molding company specialized in providing customized, high-quality plastic parts and components. As an ISO 13485 certified manufacturer with expertise in injection molding from prototyping to full production, Seaway Plastics can handle a wide range of projects. Their team of highly skilled engineers guide customers on selecting optimal materials, mold designs and manufacturing processes based on specific requirements. Seaway Plastics’ state-of-the-art facility houses advanced injection molding machines from 40 to 3,000 tons, enabling production of a diverse range of parts. Their commitment to innovation and quality is demonstrated through utilizing latest technologies such as building all-aluminum, aluminum-steel or all-steel molds from Class 105 to 101 quickly. Leveraging expertise and resources, Seaway Plastics delivers precise plastic injection molding solutions meeting standards across industries.

Founded Year: 1962

Location: CA, United States

Business Type: Plastic molding manufacturer, Injection mold manufacturing.

Offer Services: Plastic Injection Molding, Tooling and Fabrication, Water Injection molding, Plastic Mold Repair & Maintenance, thin wall injection molding.

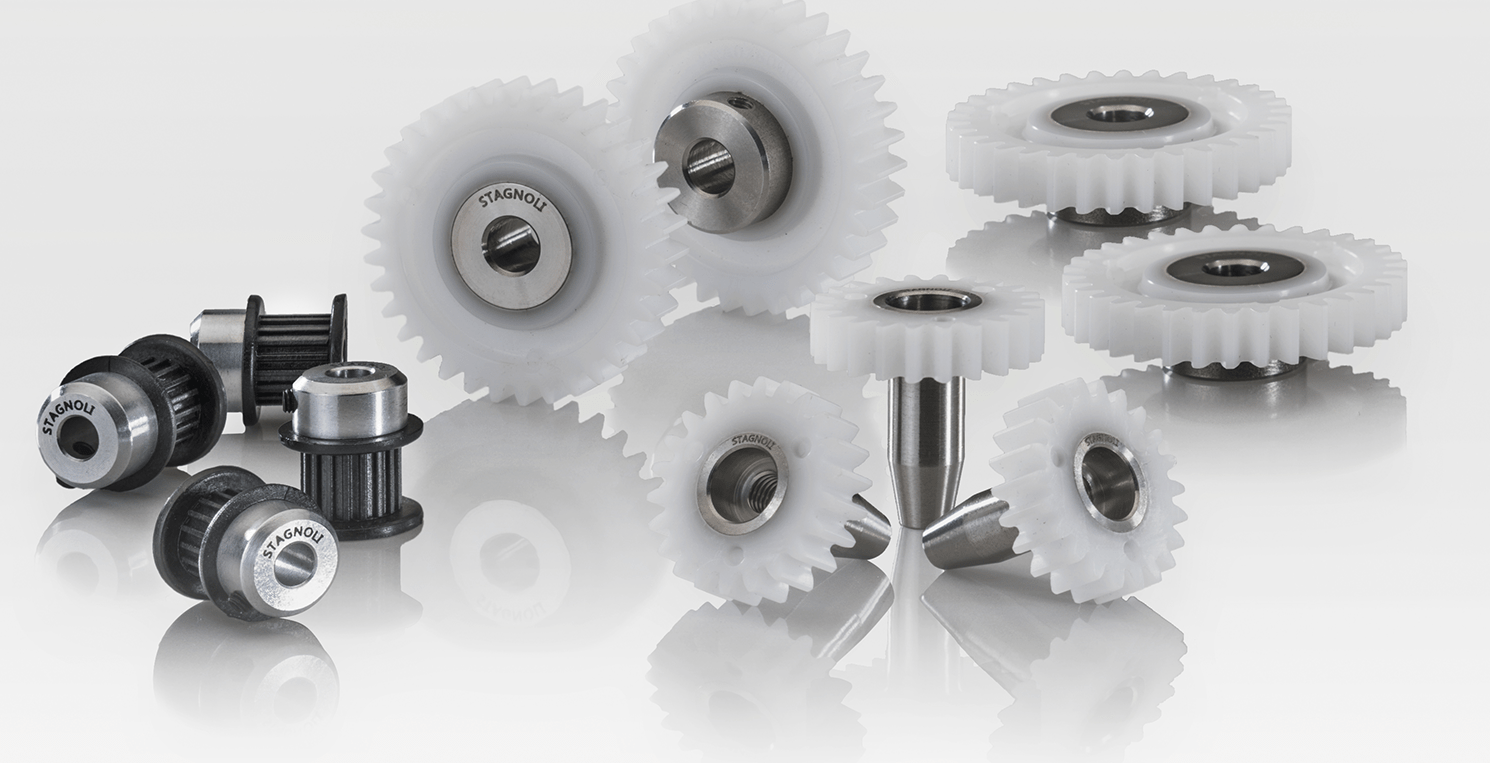

Universal Plastic Mold (UPM) is a supplier of comprehensive plastic injection molding solutions, serving diverse industries for over 60 years. As an ISO9001 and IATF 16949 certified manufacturer specializing in high-tonnage custom and large-part molding, and Magnets injection molding and silicon encapsulated magnets is also their specialty.UPM offers one stop service capabilities including mold design, tooling, post molding operation (sonic welding, paint, printing, plating, vapor deposition) and logistics. Operational from a 127,000 square-foot facility equipped with advanced machinery and a team of over 300 skilled employees, UPM is committed to delivering high-quality plastic molded products and exceptional customer service. Leveraging a strategic coastal location to enable cost-effective overseas sub component manufacturing and streamlined U.S. assembly, UPM aims to be a trusted, full-service partner helping customers simplify manufacturing processes and achieve goals through innovative plastic injection molding capabilities that have made them a preferred supplier for multiple industries over six decades.

Founded Year: 1982

Location: NJ, United States

Business Type: Injection molding manufacturer, injection mold tooling manufacturer

Offer Services: plastic product design & development, injection molding, custom plastics molding, 3d printing prototyping, mold making & design, automation injection molding, low volume injection molding.

Bennett Plastics is a customer-focused injection molding company founded in 1982. Their team of skilled engineers and technicians collaborate closely with customers to deliver innovative and tailored plastic injection molding solutions, whether intricate medical devices, durable industrial components or complex consumer goods.

As a vertically integrated injection molding manufacturer, Bennett Plastics offers a full suite of plastic molding services including product design, rapid prototyping via 3D printing, plastic mold building with CNC machining, metal injection molding, filter injeciton moding and high-volume plastic mass production using advanced injection molding machines. This integrated capability allows strict quality control to consistently meet stringent regulatory standards for medical, industrial and consumer customers. Leveraging its expertise in plastic part and mold design, material selection, and process optimization, Bennett Plastics delivers customized plastic solutions that meet customers’ injection molded component needs.

Founded Year: 2006

Location: TX, United States

Business Type: Plastic injection molding manufacturer, scientific molding.

Offer Services: Injection Molding, Plastics Engineering, Injection Mold Design & Tooling, Plastic Injection Molding, Plastic Blow Molding, prototyping, paint, printing.

Texas Injection Molding is a leading supplier of precision plastic parts and engineering services for manufacturers across multiple industries. Their operating from 65,000 square-foot injection molding facility, Texas Injection Molding supports customers through plastic injection molding solutions – including product design, material selection, mold making, and production over its range of injection molding machines. They have 29 injection molding machines ranging from 55 tons to 1,100 tons and an in-house mold tool shop to provide rapid repair and mold making.

Drawing inspiration from the pioneering Texas spirit, the company is committed to delivering high quality injection molded components and assemblies from its sizable facility. Leveraging decades of expertise in plastic injection molding, Texas Injection Molding provides solutions to a diverse client base in vital sectors such as energy, life sciences, electronics, and manufacturing. The supplier positions itself as a premier partner for injection molding services.

Founded Year: 1999

Location: MN, United States

Business Type: Custom injection molding manufacturer, plastic Mold manufacturer, plastic molding factory.

Offer Services: Injection Molding, Injection Molding, CNC Machining, 3D Printing, Sheet Metal Fabrication, injection mold manufacturing.

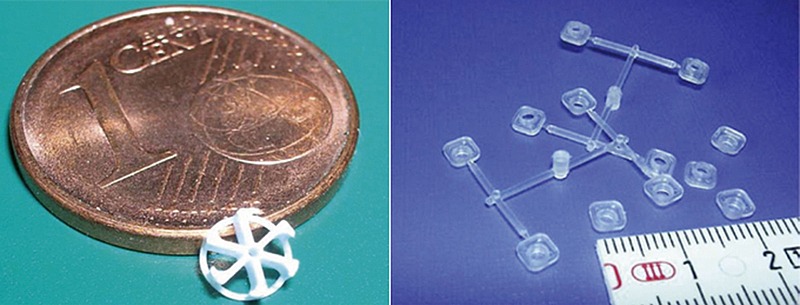

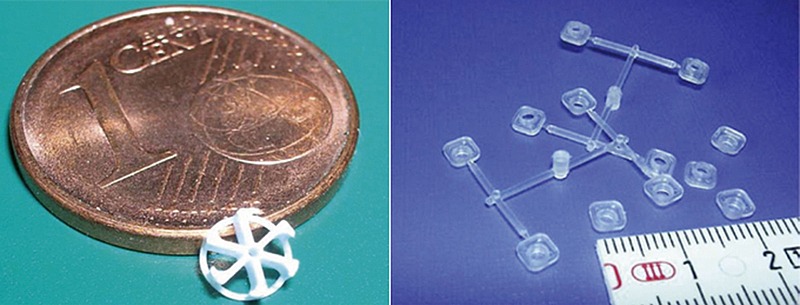

As a pioneer in digital manufacturing, the company was founded in 1999 with the goal of revolutionizing the production of injection molded prototypes through innovative software and automation. Over the past two decades, Protolabs has expanded its capabilities beyond injection molding to include metal and plastic CNC machining, 3D printing, and sheet metal fabrication, offering customers a comprehensive suite of digital manufacturing solutions. The company’s network of highly vetted global manufacturing partners further enhances its ability to deliver advanced capabilities, improved cost-efficiencies, and higher part quantities. Protolabs has established itself as a trusted partner for businesses seeking thin wall molding, micro molding and other cutting-edge injection molding manufacturing services.

Founded Year: 1956

Location: PA, United States

Business Type: Injection molding manufacturer, injection Toolmaker.

Offer Services: Plastic Injection Molding Design, toolmaking, cleanroom injection molding, injection material selection, insert molding, plastic 3D printing, design & engineering, ultrasonic welding, plating, paint.

For nearly 70 years as a family-owned business, The Rodon Group has served as a trusted resource for precision custom injection molding within diverse industries. Operating over 100 injection molding machines across its facilities, they have grown to become one of the largest domestic injectors in the U.S., incorporating automation and robotics into efficient production workflows. Committed to sustainable and quality manufacturing practices, Rodon Group takes an environmentally-conscious approach through competitive pricing under its “Cheaper than China®” model. This enables the in-house production of premium American-made plastic injection molded parts and products compared to companies outsourcing overseas. Rodon Group continues to advance domestic injection molding capabilities and reshore global supply chains by helping billions of plastic components return to U.S. production floors through dedicated Made-in-America operations.

Founded Year: 1992

Location: Georgia, United States

Business Type: Injection molding manufacturer, injection tooling manufacturer, injection mold supplier.

Offer Services: Plastic Part Design and Engineering, Plastic Injection Mold building, mold materials selection, post molding operations, untrasonic welding, metal insert molding, two color injeciton molding.

Murray Plastics is a vintage injection molding manufacturer that designs products, builds molds, production parts, and performs a variety of secondary operations. They are a leading American integrated custom injection molding solutions provider with over 30 years of experience in product design, plastic molding, and production of quality plastic parts and components. Operating an advanced 5,000 square-foot factory in Gainesville, Georgia, the company injection molds various thermoplastic materials including eco-friendly ones for different industrial customers and also provides low volume injection molding.

Murray Plastics’ industry experts and engineering teams work closely with clients to develop innovative injection molding solutions from small plastic parts to large assemblies, covering concepts, molds, and injection production. The company is committed to being a competitive domestic manufacturer of plastic components while offering value-added injection molding services including plastic products warehousing, distribution, and mold maintenance.

Murray Plastics places emphasis on quality management, technical exploration and customer satisfaction, positioning itself as a trusted partner for companies seeking reliable, high-performance plastic injection solutions.

Founded Year: 1946

Location: PA, United States

Business Type: Injection molding manufacturer, injection tooling manufacturer, scientific injection modling, injetion mold supplier.

Offer Services: Plastic Part Design and Engineering, Plastic Injection Mold making, automation injection molding, design for manufacturabilitiy, mold flow analysis, two shot injection molding, metal injection molding, overmolding magnets, brass nut insert molding.

Crescent Industries, Inc. specializes in custom plastic injection molding. They provide custom molded components and offer extensive services to complete your project and reduce your supply chain. Additional post-molding services are also available including part decoration, plating, screen printing etc. Their manufacturing processes are based on scientific injection molding, decoupling II and decoupling III molding techniques. They have a project management office which includes R&D pressure machines used for setup and sampling of new injection molds. Their most advanced quality lab and equipment validate their 100% investment in quality standards. As an ESOP company, every employee is committed to the success of Crescent and its customers.

For 75 years, Crescent Industries, Inc. has been committed to providing the most viable injection molding manufacturing solutions and becoming the premier American injection molder. They have consistently provided quality injection molds and plastic components to customers. Crescent has the capability to handle the most complex medical devices and equipment at Class I, II, III levels within their ISO 13485:2016 and FDA registered facilities (including 10K and 100K cleanrooms). Through ITAR registration and FFL, they can also process various plastic products and components in the most sensitive applications including large plastic parts and ultra thin wall plastic parts. Their extensive value-added capabilities provide competitive plastic molding supply chain solutions through implementation of QRM, collaborative robots and complete automated cells. Crescent Industries, Inc. is a reliable partner to fulfill all your plastic molding and plastic tooling needs.

Founded Year: 1980

Location: CO, United States

Business Type: Plastic injection molding manufacturer, injection tooling manufacturer, plastic molding supplier.

Offer Services: Injection Molding, design & Engineering Services, Assembly & Packaging, Automation Design & Implementation, Part Decorating, Mold Development, in-mold decoration, pad printing, screen printing, laser marker, plating.

Company Profile

Intertech Plastics is a premier custom injection molding manufacturer located in Colorado with over 40 years of experience specializing in the production of highly engineered, close tolerance plastic parts and assemblies including high-performance plastics molding. They are committed to providing zero-defect solutions through innovative injection molding processes and automation. Intertech’s expertise spans a wide range of capabilities including product design, engineering, mold development, assembly and packaging operations downstream of molding. The company operates injection molding machines of various capacities, ranging from 30 tons to 1,500 tons, capable of handling plastic applications such as automotive, medical, consumer and aerospace. Intertech’s commitment to quality assurance is evidenced through their use of automated quality compliance systems and real-time process control to ensure consistent and repeatable part production to within one millionth of an inch precision. Their focus on injection molding defect prevention and continuous improvement has earned the company numerous industry awards and designation as a Top 100 Plastics Processor annually. Their passion and expertise for plastics propels them as a leader in the injection molding industry providing excellent turnkey injection molding solutions.

Founded Year: 2000

Location: CA, United States

Business Type: Plastic injection molding manufacturer, mold maker, injection molding tooling manufactuer.

Offer Services: Engineering, Hot stamping, In-mold labeling injection and blow molding, Mold making in house, Plastic products design assistance, Screen printing/pad printing, Secondary operations, ultrasonic welding, Tooling/mold design, Turnkey injection molding solutions, thin wall molding, filter injeciton molding.

Company Profile

Valencia Plastics was established in 2000 as an one-stop injection and blow molding manufacturer primarily serving the aerospace, medical, commercial, military and pharmaceutical industries with high quality plastic products. The company has built a reputation for providing excellent plastics, competitive pricing and on-time delivery.

Valencia Plastics is committed to sustainability and partners with leading recycled resin manufacturers to reduce its environmental impact. The company places emphasis on quality assurance and leverages its extensive injection molding experience as well as state-of-the-art injection molding machines to produce a variety of injection and blow molded plastic parts ranging from micro molding plastic parts and components to large plastic components weighing up to 7 pounds utilizing their production capabilities and expertise.

Founded Year: 1987

Location: CA, United States

Business Type: Plastic injection molding manufacturer, injection mold manufacturer, blow molding manufacturer, injection molding supplier

Offer Services: product design, 3D printing, rapid prototyping, mold/tooling making, injection molding, blow molding, clean room molding, micro molding, liquid silicone molding, rotational molding, extrusion molding, two color silicone rubber molding, metal stamping.

Company Profile

Hi-Rel Plastics & Molding is an experienced custom injection molding and blow molding supplier and manufacturer. For over 35 years, Hi-Rel has partnered with clients across multiple industries to provide specialized plastic molding solutions.

Services include 3D printing, prototyping, mold designing, tooling production, as well as injection and blow molding of thermoplastics and engineering-grade resins, including high performance plastics such as PEEK, PPS, PEI, PAI and nylon. Hi-Rel’s experienced technicians help evaluate designs and ensure precise production of low volume plastic molding medical devices and high-end components to a tolerance of ±0.001 inches.

By committing to quality parts, on-time delivery and superior customer service, Hi-Rel has grown to become a premier provider of complex molding solutions, serving the medical, aerospace, military and scientific sectors. As a leading custom injection molding manufacturer and mold maker, Hi-Rel leverages extensive process expertise to reliably deliver high-tolerance molded components and assemblies.

Founded Year: 2010

Location: IN, IL, TX, WI, PA, CO, NL, MI, United States.

Business Type: Plastic injection molding manufacturer, plastic Mold maker, Machinery Processor, injection molding maker, plasitc molding supplier.

Offer Services: Custom Plastic Injection Molding, Insert Molding, double injection molding, Tooling and Prototype making ,Painting & Finishing, Tool Design and Build, Sheet Metal Fabrication, Sheet Metal Stamping, Precision CNC Machining, Welding, Plastic Injection Molding, Overmolding, Structural Foam Molding.

Cadrex is an injection molding manufacturers that provides end-to-end solutions for customers from concept to scaled production in the USA. The company was established through acquiring several renowned manufacturing enterprises, including CGI Automated Manufacturing, Richlind Metal Fabricators, Precision Tool & Die, Elite Manufacturing Technologies, Advanced Laser, and Haven Manufacturing.

Cadrex is one of the largest injection and mechanical solutions providers in North America, with 21 manufacturing facilities across 10 states in the United States and Mexico. The company works with some of the most innovative enterprises in the world and provides customized manufacturing services leveraging its expertise and technological advantages in industries such as information and communication technology, warehouse automation and robotics, aerospace and defense, renewable energy and power infrastructure, medical and so on. Cadrex has advanced injection molding equipment and fully automated production lines that can meet customers’ quality and certification requirements, being a trustworthy partner in customers’ supply chain.

Founded Year: 2000

Location: USA, ASIA, EUPOPE

Business Type: Custom plastic injection molding manufacturer, plastic Mold manufacturer, injection molding maker.

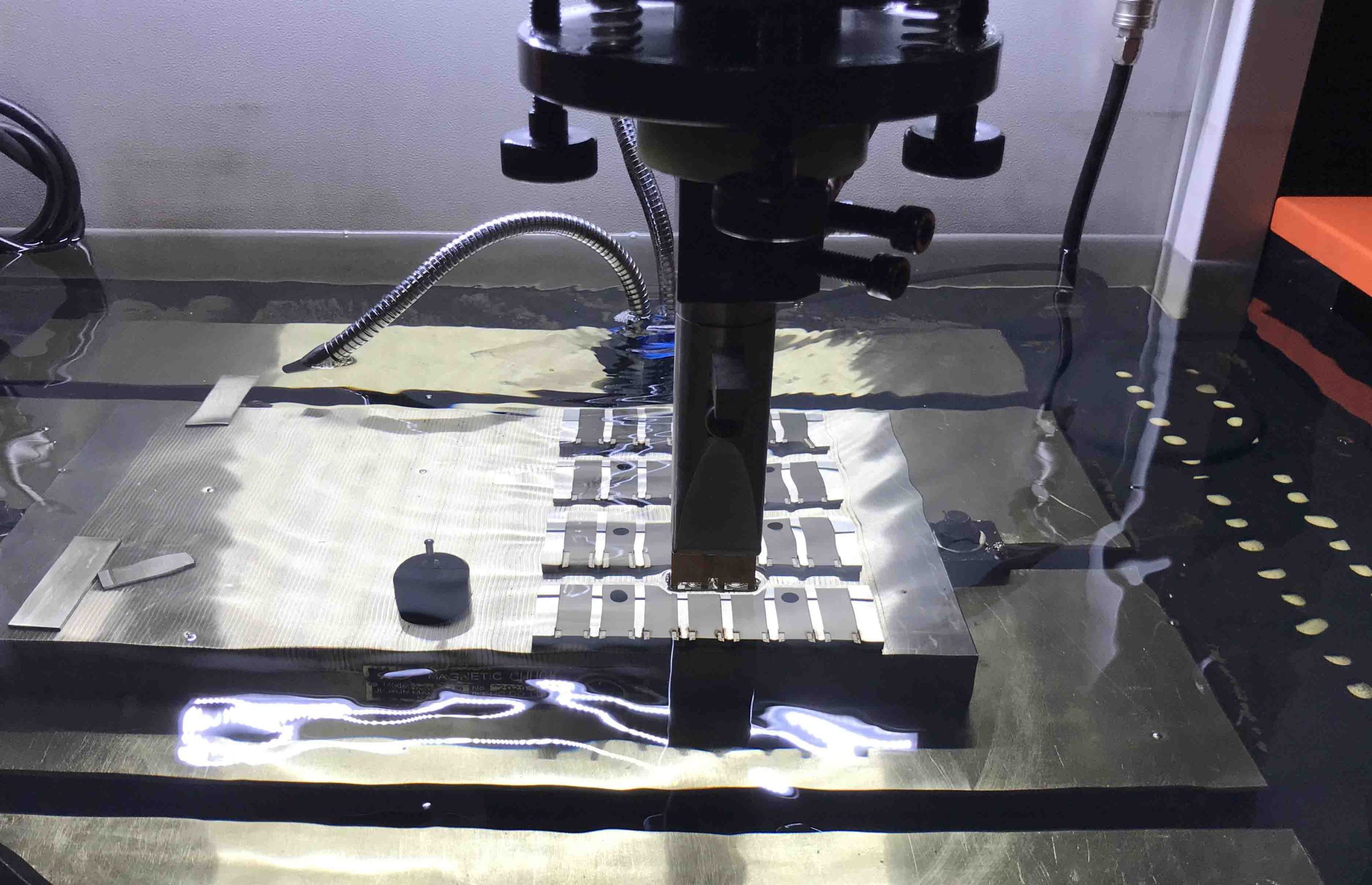

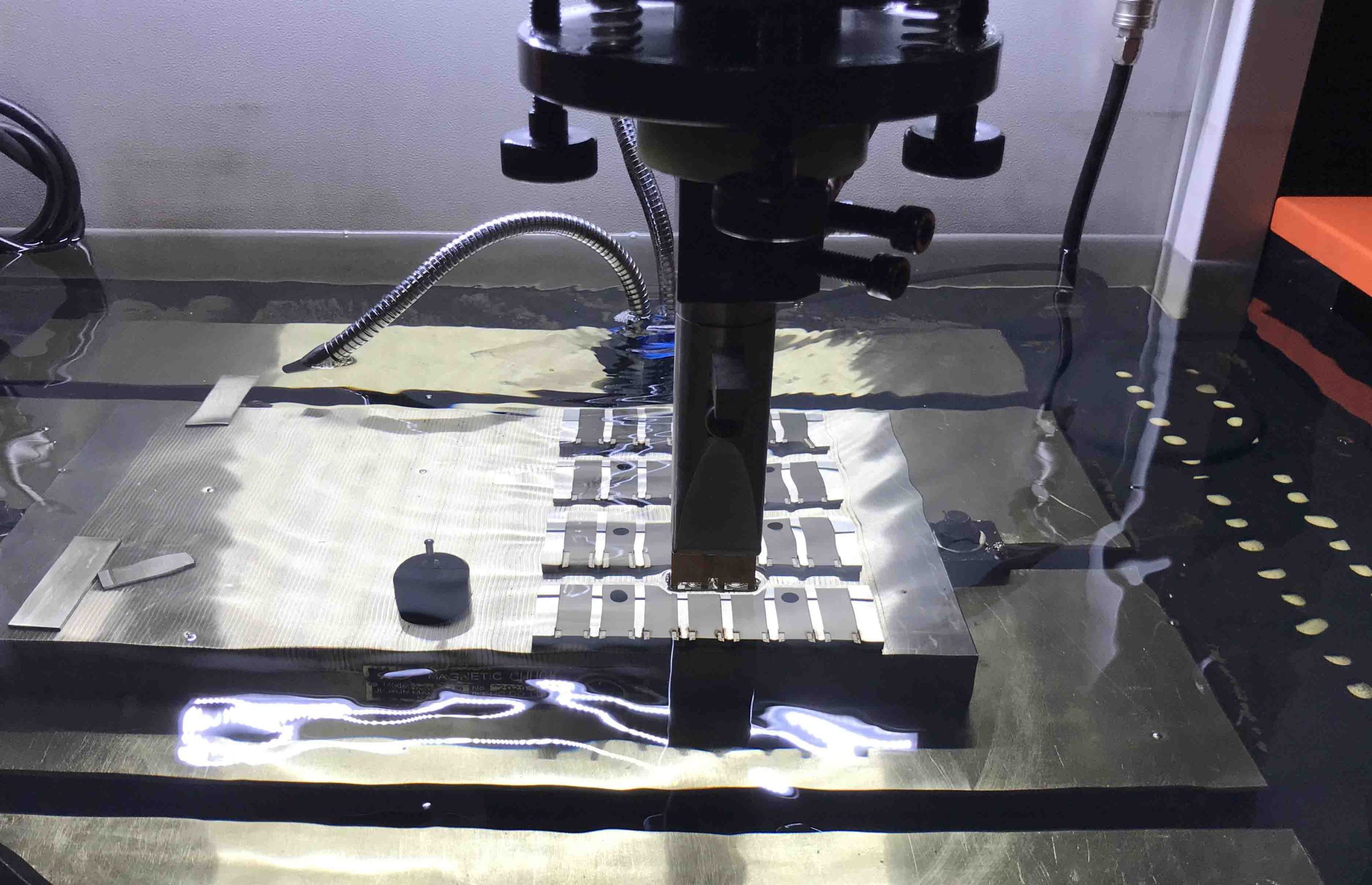

Offer Services: Custom injection molding, metal insert Molding, 2K molding, double injection molding, CNC Machining, CNC Milling, CNC Turning, CNC Routing, Wire EDM Machining, plastic and metal CNC machining, CNC Routing, Prototype Molding, Bridge Molding, Plastic Production Molding, Overmolding, Insert Molding, Urethane and Silicone Casting, Injection Molded Surface Finishes, Custom Plastic Fabrication, Micro Molding, Metal Injection Molding, Die Casting, Metal Stamping, Plastic 3D Printing Service, Metal 3D Printing, Direct Metal Laser Sintering, Metal Binder Jetting, Vapor Smoothing 3D Prints.

Xometry is a leading provider of comprehensive manufacturing services, including advanced plastic injection molding capabilities. As a plastic injection molding manufacturer, Xometry specializes in delivering high-quality, on-demand injection molded parts for both prototypes and production. Their extensive capabilities cover a wide range of injection molding processes, including micro molding, insert molding, overmolding, and more. Leveraging their vast network of vetted injection molding suppliers, Xometry offers customers a diverse selection of plastic materials, finishes, tolerances, and certifications. Their injection molding machines and skilled technicians ensure consistent, precise part production, even for complex designs.

Whether prototype plastic injection molds or high/low volume production is required, or specialized micro-scale parts, Xometry’s comprehensive capabilities and user-friendly platform make them a trusted partner for industries including medical, electronics, automotive, and aerospace. With commitment to quality, innovation, and customer satisfaction, Xometry stands out as a leading plastic injection molding manufacturer and mold manufacturer. Their advanced injection molding expertise also positions Xometry as a premier solution for businesses seeking custom injection molding, connector molds, medical device molds, and automotive component molds.

Founded Year: 1986

Location: WI, United States

Business Type: Injection molding manufacturer, plastic Mold making plastic product designer, plastic molding manufacturer.

Offer Services: Custom Plastic Injection Molding, Design For Manufacturbility (DFM), injection mold making, Post Molding Operations and Assembly, Additive Manufacturing, Insert Molding, Tooling and Prototype Support, plastic intgrated silicone molding.

For 35 years, Nicolet Plastics has been pioneering custom plastic injection molding. Headquartered in Mountain, Wisconsin, the company specializes in providing comprehensive injection molding services including mold design, plastic tooling and part production. Their expertise surpasses conventional injection molding and includes innovative technologies such as 3D metal printing for rapid tooling. Nicolet’s team places emphasis on quality control, leveraging advanced molding processes, material handling and part inspection to ensure consistency and high precision of plastic components. The company’s commitment to continuous improvement and employee development has earned it recognition as Wisconsin Manufacturer of the Year. Nicolet Plastics serves industries ranging from medical devices to consumer goods, understanding their unique needs and providing customized injection molding services. The company has been rated among the 2023 Top 100 Injection Molding Companies in the US. It is an ideal innovative plastic molding solutions partner.

Founded Year: 1996

Location: MI, United States

Business Type: Injection molding manufacturer, plastic mold manufacturing, product design, injection mold tooling maker.

Offer Services: Custom Plastic Injection Molding, Plastic Injection Molding Services, Prototype Injection Molding, Injection mold Making, CNC Machining Services, Rapid Prototyping Service, 3D Printing, filter injection molding.

Xcentric Mold & Engineering was established in 1996 as a top injection molding supplier offering integrated injection molding services, rapid prototyping, CNC machining and 3D printing. Headquartered in Clinton Township, Michigan, the company is renowned for outstanding production efficiency and advanced technology usage. Xcentric’s custom plastic injection machines and automation cells are designed around a core philosophies emphasizing speed, stability, flexibility and quality. The team consists of injection molding experts, experienced industry veterans, 3D designers and in-house mold makers. This “engineer-centric” approach enables the company to deliver customized plastic injection components, CNC machined parts and 3D printed projects within just 10 working days. Leveraging over 25 years of industry experience, Xcentric continuously innovates and leads advancements in the fields of injection molding and rapid prototyping.

Founded Year: 1982

Location: CO, United States

Business Type: Injection molding manufacturer, plastic Mold manufacturing, product design, injection mold maker.

Offer Services: Plastic Injection Molding, Prototyping & Product Development, Injection Mold Design & Tooling, Plastic Engineering and Design, Plastic Thermoforming, silicone rubber molding, magnets injection molding.

Founded over 40 years ago, Plastikon is a premier injection molding supplier of molding, assembly and turnkey project management as a one-stop plastic injection molding company and engineering partner with global reach. Its mission is to become the world’s leading plastics and contract manufacturer. They rely on advanced injection molding equipment, technology and talented employees to provide high-quality plastic products. Plastikon not only has proven experience in mold design and production, but also has unique insights in DFM and mold flow analysis. Plastikon and Plastikon Healthcare have grown into U.S. injection molding leaders in lean manufacturing.

Founded Year: 1977

Location: CA, United States

Business Type: Custom Injection molding manufacturer, percision plastic mold manufacturing, micro mold making.

Offer Services: Plastic Injection Molding, Product Development, Injection Mold making, plastic part design, tooling engineering, mold maintenance, mid and high volume molding.

Located in the heart of downtown Denver, Colorado, LTM Plastics is a family-owned business that has been in the plastic injection molding industry for over 50 years. Originally starting as a traditional tool shop, over decades of operations LTM Plastics has evolved into a cutting-edge injection molding factory. With years of stringent quality control and quality requirements, they have been recognized as one of America’s Top 100 Injection Molders for 2023. Their modernized injection molding facility features 18 all-electric, Japanese-branded injection molding machines operating 7 days a week, 24 hours a day, greatly improving part quality while shortening lead times. Capable of handling any plastic application for injection molding with tonnages ranging from 50 to 500 tons, LTM Plastics holds the flexible capacity needed for all sized projects.

Founded Year: 1998

Location: NY, United States

Business Type: Custom Injection molding manufacturer, percision plastic Mold manufacturing, injection mold maker, injection tooling manufacturer.

Offer Services: Design & Development, Custom Injection Molding, Injection molding contract Manufacturing, injection mold tooling making.

Natech Plastics was founded in 1998 by German masters mold maker, it is a prominent plastic injection molding company based in United States, renowned for its expertise in plastic molding and the production of precision plastic injection molds. As a key player among top injection molding companies, Natech Plastics has established a strong reputation for delivering high-quality plastic injection molding services. The company operates advanced injection molding machines, which enables them to cater to a wide array of industries, including the medical sector with their medical injection molding capabilities.

Natech Plastics is also adept at creating prototype models, showcasing their ability to support clients from the concept stage to full-scale production. In addition to their focus on custom injection molding, Natech Plastics excels in low volume injection molding companies, providing tailored solutions to meet specific customer needs. They are known for their plastic injection molding suppliers network and their commitment to offering competitive pricing and exceptional service. Natech Plastics maintains a robust presence in the plastic molding manufacturers and mold manufacturers space, with a particular emphasis on China plastic machine technology and innovation. Their services extend to plastic mold injection companies and injection molding companies, ensuring a comprehensive approach to plastic injection molding and molding manufacturers services.

Founded Year: 1970

Location: MI, United States

Business Type: Custom Injection molding manufacturer, percision plastic Mold manufacturing, plastic molding manufacturers.

Offer Services: Custom Injection Molding, custom mold making, plastic products development, design & engineering, 3D printing, pad printing, laser marker, plating.

Revere Plastics Systems LLC is a distinguished plastic molding manufactueres that specializes in the manufacturing of precision plastic components. The company is known for its advanced injection molding machines and its commitment to excellence in the plastic molding industry. Revere Plastics Systems operates as a top 100 injection molding company, offering a wide range of services that include custom injection molding and the development of complex plastic injection molds. They pride themselves on being a plastic injection molding supplier that caters to various industries, including the medical sector with their specialized medical injection molding, magnets injection molded services. The company’s facility functions as an injection moulding factory equipped with the latest technology, enabling them to produce high-quality plastic moldings and plastic injection molding components. Revere Plastics Systems is also adept at creating prototypes and working with low volume injection molding, showcasing their flexibility and adaptability to meet diverse customer needs. As a plastic mold manufacturers and molding companies, Revere Plastics Systems is dedicated to innovation and quality, ensuring that their plastic injection molding companies and plastic mold injection companies services stand out in the market. they have positioned themselves as a competitive player in the global plastics injection molding companies landscape.

Founded Year: 1980

Location: IL, United States

Business Type: Custom Injection molding manufacturer, percision plastic Mold manufacturing.

Offer Services: Custom Injection Molding, custom plastic mold making, mold design, mold analysis, tooling machining, plastic products design, 3D printing, pad printing, laser marker.

Hansen Plastics is a strong plastic molding company in USA. They focus on innovation and precision, providing comprehensive services to customers, including design and manufacturing of plastic injection molds as well as production of high-quality plastic parts. As an important participant in top-tier injection molding companies, Hansen Plastics has over 70 injection machines, ensuring its position as the industry standard for plastic molding service companies. Their expertise in various material sciences has earned them high recognition from many custom injection molding firms.

Hansen Plastics also stands out for its commitment to micro-injection molding companies, providing professional services for medical device production. Their expertise in medical device injection molding ensures they comply with strict quality and regulatory requirements, making them a trusted partner for healthcare-related projects. In addition to their work in the medical field, Hansen Plastics is also renowned for its capabilities in small volum injection molding companies, enabling them to provide flexible and cost-effective solutions for smaller production runs. Coupled with being a domestic plastic injection molding supplier in the USA, this makes them a reliable choice for many multinational corporations and start-ups alike.

Founded Year: 1968

Location: MA, United States

Business Type: Custom Injection molding manufacturer, injection Mold manufacturing, injection mold maker.

Offer Services: Injection Molding, plastic mold making, mold design, mold analysis, injection mold machining, plastic parts design, 3D printing, pad printing, plating,

Company Profile

Pitts Plastics is a professional injection molding supplier focused on providing plastic injection molding and injection mold making services. As USA plastic molding company, they has 25 injection molding machines and a large-scale 64,000 square foot injection molding facility. The company employs an efficient plastic mold manufacturing process to ensure precision and consistency of products. Pitts Plastics also offers one-stop plastic molding solutions including product design, prototype development, and final plastic mold production. They currently focus on producing plastic cores, reels, spools and cones.

As one of the premier injection molding companies, Pitts Plastics also serves multiple industries including medical, automotive and consumer goods. Their in-mold decoration injection molding capability stands out in particular for meeting various decoration requirements for consumer goods. Additionally, Pitts Plastics excels at low-volume injection molding and gas assisted molding to serve customers requiring customized solutions. Through cooperation with metal insert molding companies, they can also provide plastic integrated metal manufacturing services such as insert molding magnets and overmolding magnets.