lightweight

lightweight

Improve Efficiency

Improve Efficiency

Quick Turnaround

Quick Turnaround

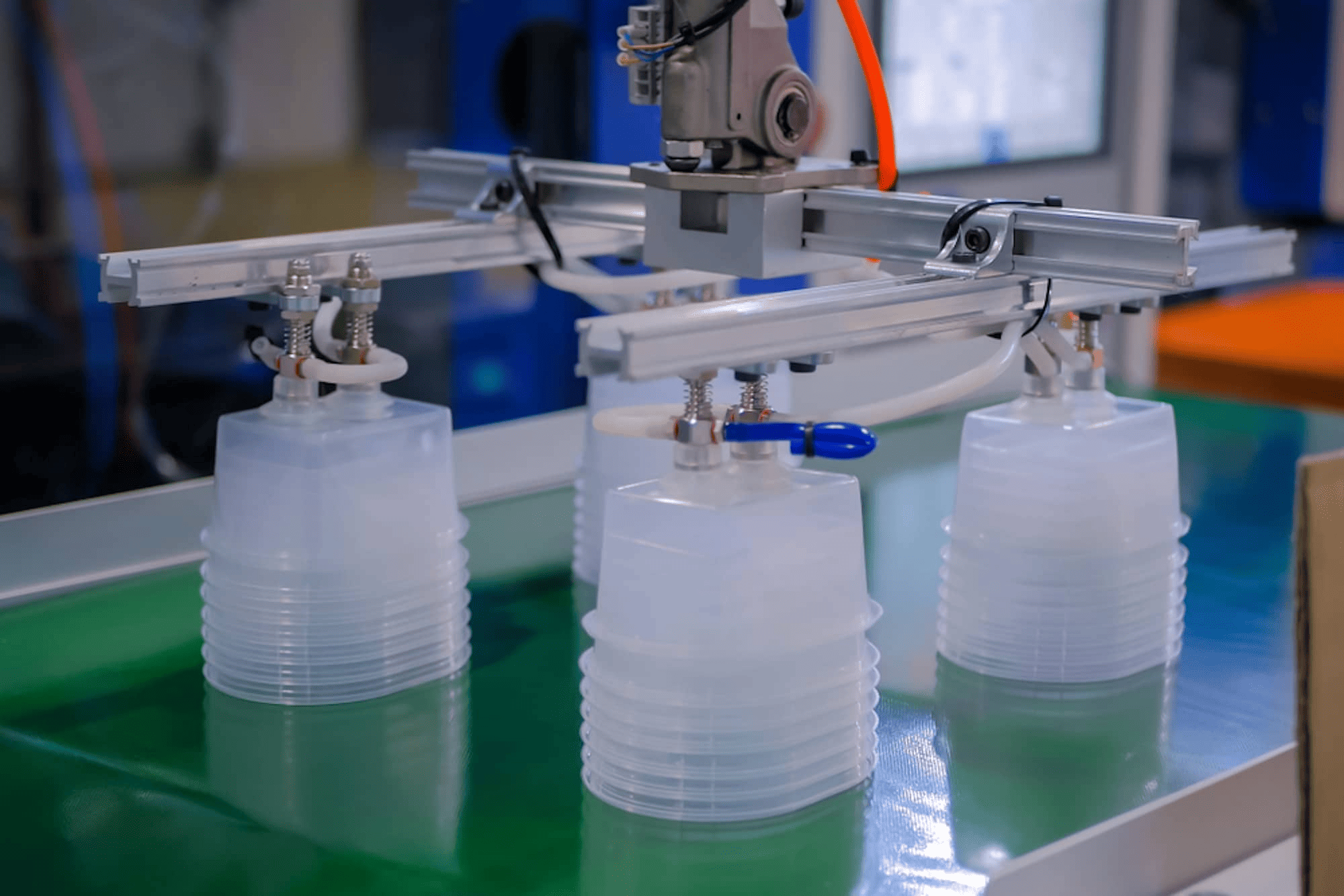

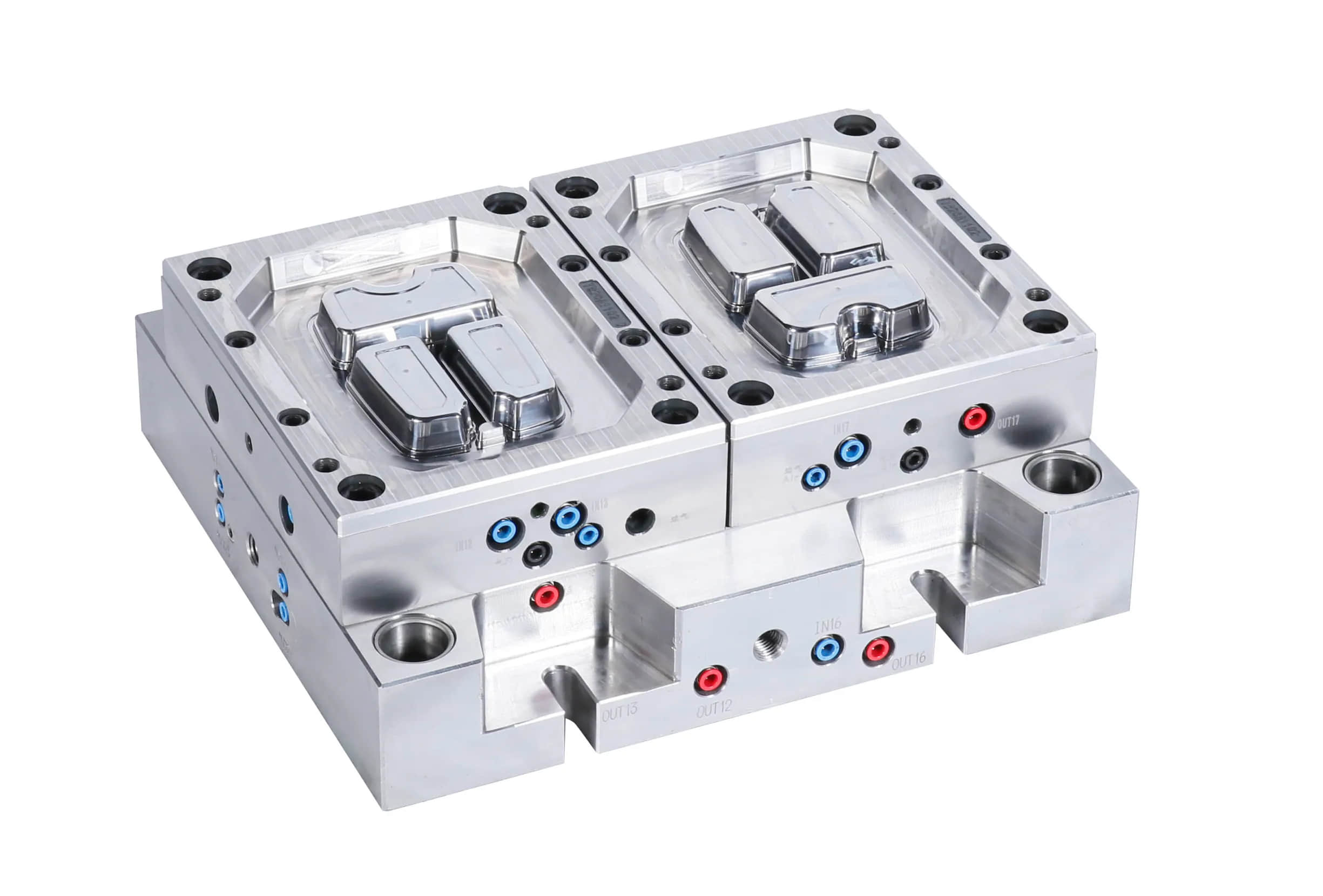

Thin wall injection molding is a specialized injection molding process for producing plastic parts with wall thicknesses below 1 mm. It requires high-performance injection molding machines, well-designed molds, low viscosity plastics, and tight process control to fill thin sections completely and minimize defects. Key applications include thin wall packaging, electronic housings, and lightweight consumer products.

These are some considerations of thin wall moling:

Producing high quality, dimensionally accurate thin wall parts via injection molding requires careful attention to process control, mold design, material selection, and simulation analysis.

Here are some key challenges associated with thin wall injection molding:

Thin-wall molding has significant advantages in reducing weight, saving materials, improving strength, saving costs, optimizing design, and facilitating integrated design and assembly. However, in practical applications, it is also necessary to select appropriate molding processes and materials based on specific product requirements and process conditions to fully exploit their advantages and overcome potential challenges. Take a look at its main advantages below: