With its unique processing principles and wide material adaptability, EDM technology provides solutions for the processing of complex shapes and hard metals. This article will delve into the definition of electric discharge machining, different types of EDM processes and applications, aiming to provide engineering technicians and manufacturing practitioners with a comprehensive overview of EDM technology.

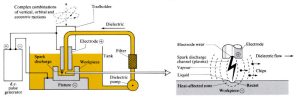

Electrical Discharge Machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, it is a special processing method that uses the instantaneous high temperature and local micro-explosive force generated by electric spark discharge to erode the workpiece. It is also a non-contact processing technology. It applies pulse voltage between the tool electrode and the workpiece, causing ionization breakdown of the working fluid between the two to form a spark discharge channel. During the discharge process, a large amount of heat energy is instantly generated in the channel, causing the workpiece material to partially melt or even vaporize, and is eroded under the action of the explosive force. By continuously repeating this process, precise machining of the workpiece is achieved.

History of Electrical Discharge Machining

The history of Electrical Discharge Machining (EDM) can be traced back to the early 20th century. This machining method was originally invented by Russian scientists Boris Lazarenko and Natalya Lazarenko in 1943. While studying the causes of material damage of electrical contacts, they discovered the beneficial characteristics of electrical corrosion phenomenon and applied it to metal processing. This discovery overturned traditional mechanical machining methods and opened up a entirely new non-contact machining technology.

As time went on, in the 1950s, this technology began to be applied in industrial production, especially in mold making and aerospace fields. The development of edm electrical discharge machining technology benefited from the progress of pulse power supply technology, making the discharge process more controllable and precise.

In the 1960s and 1970s, EDM technology began to develop towards wire cutting (Wire EDM), which made it possible to machine workpieces with higher precision and more complex shapes. Wire cutting technology uses a moving fine wire as the electrode to continuously cut materials by spark discharge, greatly expanding the application scope of EDM.

Entering the 21st century, EDM technology continues to develop with increased intelligence and efficiency brought by digitalization and automation of electrical discharge machines, realizing automation and optimization of the machining process. Meanwhile, EDM technology is also gradually developing towards microminiaturization to machine even smaller and more precise parts. Studies and optimization of the machining process, such as precise control of discharge parameters and improvement of working fluids, have further enhanced machining precision and production efficiency.

Electrical discharge machining (EDM) is a non-traditional machining technology that uses the energy of electric sparks to remove material to achieve precise machining requirements. According to different processing methods and application fields, electro discharge machining process can be divided into several types:

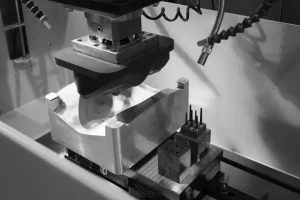

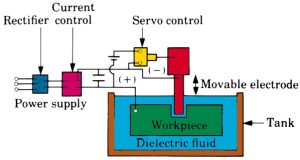

Sinker electrical discharge machining process is the most common form of EDM technology. Also known as electrode discharge machining, die sinking electrical discharge machining. it is a method of machining using shaped electrodes. In this kind of machining, the electrode (usually in a pre-designed shape) is placed above the workpiece, with a certain discharge gap between them. They are immersed in the dielectric liquid during discharge machining. By applying pulse voltage, a spark discharge is formed between the electrode and the workpiece, thereby eroding the workpiece material. Since the shape of the electrode can directly determine the final shape of the workpiece, immersion EDM is very suitable for processing complex-shaped workpieces and molds (plastic molds, stamping molds, die casting).

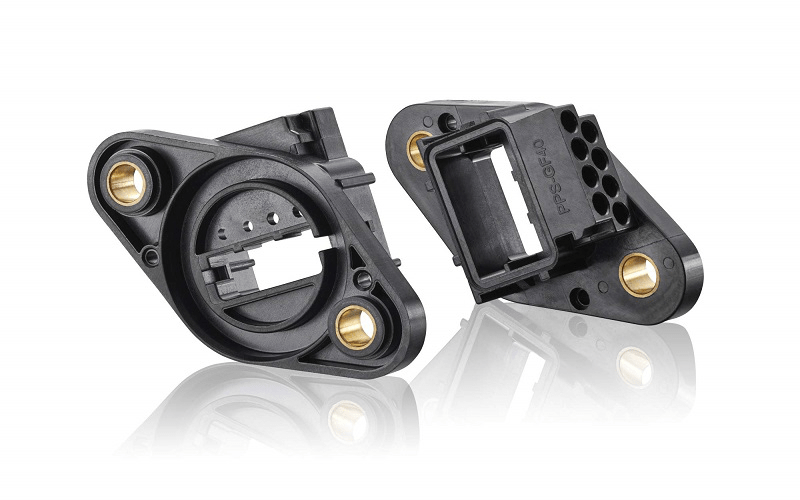

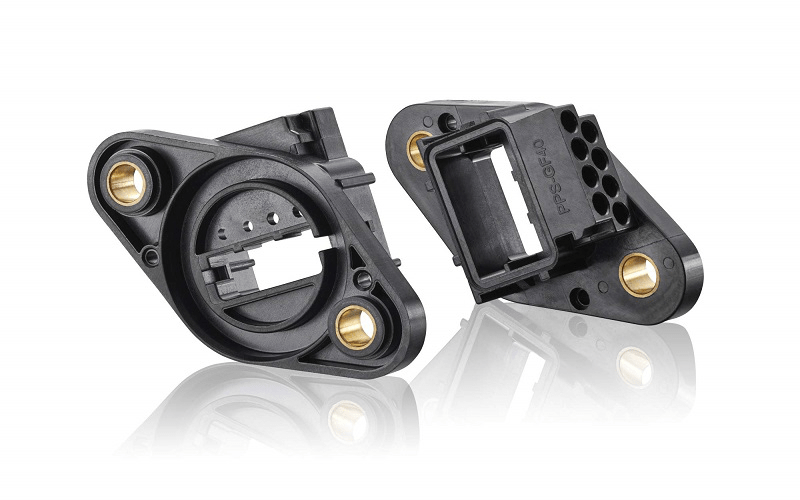

die sinking electrical discharge machining process is also commonly used for materials with high hardness and high melting point (such as cemented carbide, high-speed steel, etc.), tight tolerance parts and plastic molds, and parts with various complex structures (holes, holes, ribs), and is widely used in plastic mold manufacturing , automotive molds, medical devices molds, electronic and electrical molds and metal parts processing and other fields.

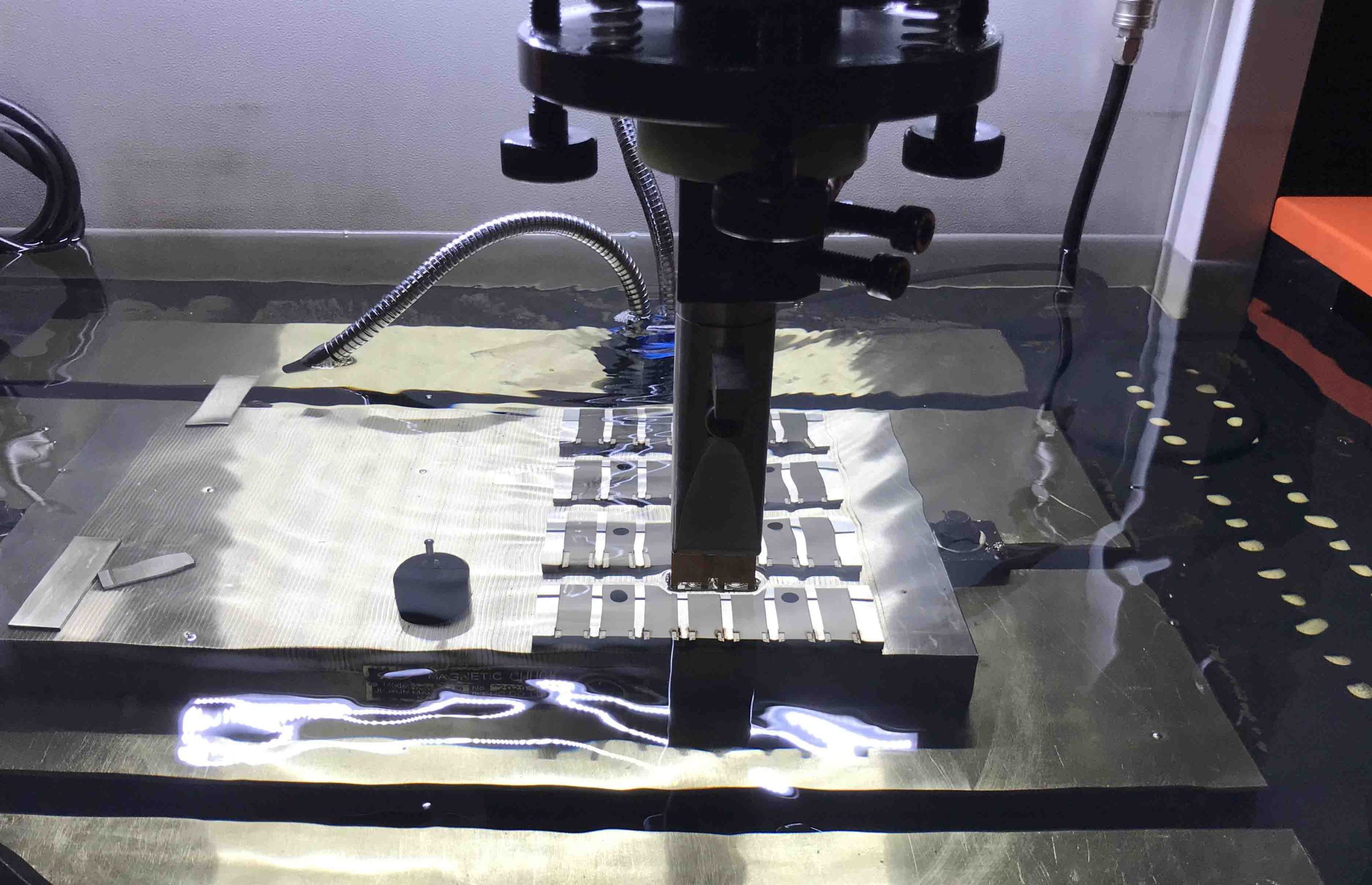

Wire electrical discharge machining (Wire EDM) is a technique that uses a continuously moving fine wire (usually made of brass, molybdenum or tungsten) as the electrode to cut materials. The fine wire is tightened and immersed in an insulating working fluid, and pulse power is applied between the wire and the workpiece to generate electric sparks for cutting. During the processing, the metal wire moves laterally along the side of the workpiece and realizes cutting of the workpiece through vertical feeding motion.

The wire material for wire EDM is made of brass, molybdenum or tungsten with diameter is 0.05 mm to 0.35 mm. Copper wire is the cheapest and tungsten wire is the most expensive. The thinner the diameter, the higher the precision of wire cutting and the easiest to break. It should be noted that the wire EDM process can’t achieve truly sharp internal corners and typically results in a tiny radius of approximately 0.13 mm to 0.15 mm. The reason is the wire also is round and will takes up space.

This edm electro discharge machining method can achieve precise cutting of workpieces of various shapes, especially suitable for machining small holes, narrow slots, deep ribs and complex profiles. It is not affected by the hardness of the material as long as it is conductive. Wire EDM is widely used in injection tooling manufacturing, electronic component processing and other fields.

According to our experience, cutting usually begins from the center or edge. Cutting from the center requires using an EDM drill to drill a small hole to allow the wire to pass through. Cutting from the edge doesn’t require this step.

Hole drilling EDM is a technique that uses a minute electrode to drill holes on the workpiece surface. This method is suitable for machining complex structure holes such as deep holes and blind holes, as well as holes that are difficult to machine with conventional methods in hard materials. It can realize high precision and high aspect ratio machining.

In this machining process, the electrode is usually a long slender copper metal tube, with its tip as the discharge point. When pulse voltages are applied, the metal tube rotates around the workpiece, generating electric sparks between the electrode and the workpiece to erode and gradually form holes of the required diameter and depth. This machining method has the characteristics of fast machining speed, smooth hole walls and high machining accuracy. Hole drilling EDM is commonly used in aerospace, automotive and other industries for processing parts such as aircraft turbine blades, mold making and automobile fuel injector nozzles.

The entire EDM processing process is a repeated and continuous plasma discharge process, which uses the energy of electric sparks to perform precise material removal, thereby achieving the processing requirements of complex-shaped precision plastic molds and metal parts.

In EDM processing, there is no need for physical contact between the electrode and the workpiece. The workpiece and electrode are immersed in the medium liquid (usually deionized water or kerosene), and a certain gap distance is maintained. Injection mold electrodes are usually made of conductive materials (such as copper or graphite), and their shapes are designed to be the negative shape of the workpiece to be processed.

There is a gap is maintained between the tool and the workpiece. This gap is usually filled with a liquid called a discharge medium (such as deionized water or mineral oil). When the gap between the two electrodes reaches an appropriate distance, the applied pulse voltage will breakdown the working fluid and generate spark discharge.

When DC power is applied between the tool and the workpiece, a series of rapid succession of electrical pulses is produced. Since the voltage output by the pulse generator is enough to cause breakdown of the working fluid, a tiny plasma channel will be formed in a short period of time. The high temperature of the plasma (the temperature can reach more than 10,000°C) will instantly cause the melting or evaporation of the workpiece material in the channel. The plasma channel generated each time only exists for a few microseconds, but through high-frequency repeated discharge , will gradually wear away a thin layer of material in the corresponding area of the workpiece surface. By precisely controlling the position of the electrode and the frequency of repeated discharges, directional processing of the workpiece shape can be achieved.

These high-temperature sparks melt or evaporate the material on the surface of the workpiece, and the molten material is then washed away by the discharge medium, thereby achieving material removal.

By adjusting the frequency, duration and voltage of the electrical pulse, the size and energy of the spark can be precisely controlled, thereby controlling the material removal rate and processing accuracy.

The principle of electrodischarge machining is based on generating pulsed discharges between the electrode and the workpiece, utilizing the energy during discharge to remove material to realize machining.

The main principles include:

High voltage is applied between the two poles: Establishing an electric field between the tool electrode and the workpiece.

Discharge gap: Maintaining an appropriate gap to enable discharge to occur.

Pulse power source: Providing high-energy pulsed currents.

Discharge channel: Forming a plasma channel in the discharge gap.

Material removal: The high temperature, high pressure and impact energy generated by discharge melt, vaporize and erode the material of the workpiece.

Control system: Precisely controlling various parameters such as voltage, current, gap, etc.

EDM processing occupies an important position in the mold manufacturing industry, especially for plastic injection molds, metal die casting molds and forging molds, and precision processing of stamping molds. It can make complex cavities, holes and fine grooves, and the surface finish of the processed molds is high, which reduces the subsequent manual polishing work. Of course, repairing molds is also its main work. It is an indispensable and important process for mold manufacturing.

In the aerospace field, EDM is used to process parts made of high temperature alloys, titanium alloys and other difficult-to-machine materials, such as aircraft jet engine blades, nozzles, propellers, turbine disks, compressor disks and other aerospace parts. It can ensure the high precision and complex geometry of these parts to meet the strict performance requirements, and also avoids the mechanical stress damage that may be caused by traditional cutting processing.

EDM is also widely used in medical device manufacturing, such as processing surgical instruments, such as orthopedic implants, pacemakers, etc., precision syringes and micro medical device parts. It enables burr-free, high surface quality machining to ensure the safety and reliability of medical devices.

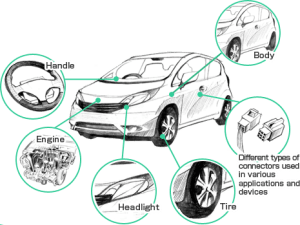

In the automotive industry, EDM is used to process engine parts, transmission parts, and brake system parts. These parts often require high precision and wear resistance, and EDM can meet these requirements while improving productivity.

In the electrical and electronics industry, EDM is used to process precision electronic components and connectors. Since electronic components often require extremely tight tolerances and complex shapes, EDM provides an effective means of machining them. It is also possible to process tiny precision parts such as printed circuit boards and micro switches. Meet the special needs of the electrical and electronics industry.

The energy industry, especially in the nuclear field, requires parts that are resistant to high pressure and high temperature, and EDM can produce parts that meet these extreme requirements, such as fuel rod positioning grids and cooling channels for nuclear reactors.

In Rapid Prototyping, EDM can quickly machine prototype parts from a metal block, greatly reducing the product cycle from design to validation. It is extremely helpful for new product development.

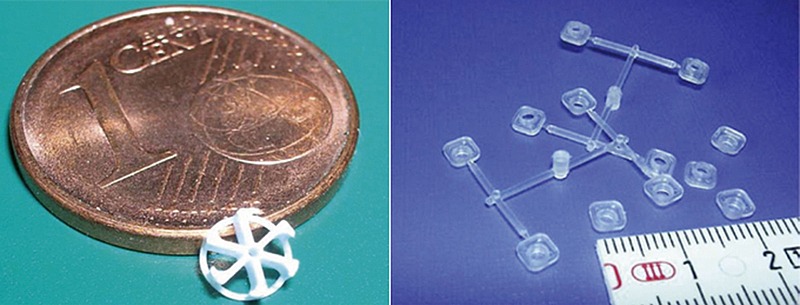

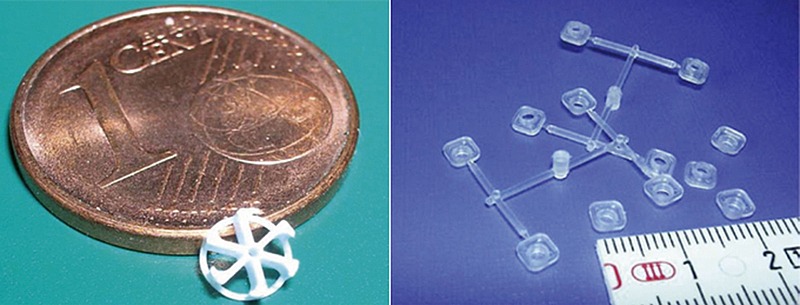

EDM enables the machining of tiny dimensions such as micro holes, micro grooves and micro gears. This is particularly important in areas like microelectronics, optics and medical devices, where tiny dimensions and precision of parts are required.

EDM can also be used to improve the quality and properties of metal surfaces. By controlling the discharge parameters, burrs and oxides can be removed from metal surfaces, improving finish and enhancing wear resistance.

EDM can process a variety of difficult-to-machine tools and molds, like tungsten steel tools and diamond tools. It can realize high-precision, high wear-resistant machining, and improve the service life of tools.

As long as it is electrically conductive, no matter how hard it is, it can be machined, such as drilling holes, cutting grooves, and very small inside corners.

EDM is very suitable for customized products and small batch production, because it does not need to manufacture specific cutting tools, and can quickly adjust the machining parameters according to the design requirements to achieve diversified production.

Injection mold tooling, Die Casting, tools.

EDM is able to process high hardness and high melting point metal materials that are difficult to deal with by traditional cutting methods, such as cemented carbide, high-speed steel, tungsten steel, inconel alloy, and so on.

Since there is no direct contact between the tool electrode and the workpiece during the machining process, there is no mechanical cutting force, which can avoid the stress deformation and damage of the workpiece caused by cutting.

EDM can machining complex three-dimensional geometries, especially effective for manufacturing complex contours such as inner cavities, holes, tapered holes, sharp corners, deep ribs, small holes and other complex contours of precision plastic molds and parts.

Through precise control of discharge parameters, EDM can achieve extremely high precision and consistency of processing, suitable for mass production and precision manufacturing, such as precision injection molds, automotive plastic molds, medical equipment molds, electronic no parts molds.

Compared to cutting, EDM has relatively low electrode loss, especially when machining hard materials, and longer tool material life.

EDM allows for the machining of tiny dimensions and is suitable for the manufacture of micro injection molded parts. The highest accuracy of Charmilles brand sinker EDM machine is up to 0.00001mm accuracy.

EDM offers high material removal rates, especially when machining high melting point materials, which is a significant improvement over traditional methods.

Since EDM is contactless machining, the shape and size of the workpiece is not limited by fixtures, making machining more flexible.

No chips are generated during the EDM process, reducing material waste, and the use of discharge media controls dust and contamination during machining.

Because there is no contact during machining, the process can machine thin, tight-tolerance metal parts without distortion.

Almost all conductive materials can be processed by EDM, such as aluminum, iron, steel, gold, copper, etc.

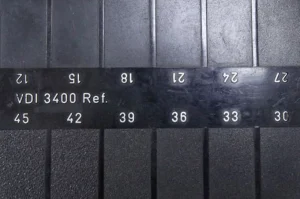

EDM machining can obtain a better surface finish, reducing subsequent finishing and polishing work. Some plastic mold surfaces can be directly referenced to the EDM processed surface. For example, the surface finish of VDI can be produced by EDM process. The best surface finish machined with EDM can reach 0.1 µm RA.

The electrical discharge machining (EDM), although it has many advantages, also has obvious disadvantages. Following are the main deficiencies and detailed explanations of EDM:

EDM can only remove a small amount of material each time, and the machining speed is relatively slow, especially when machining large workpieces, the efficiency will be lower. Compared with traditional CNC machining (CNC milling, CNC turning), EDM usually requires a longer machining time. This is because EDM relies on melting the workpiece surface by discharge, which needs to be step by step and each step needs time to wait for the material to be eroded and cooled, instead of continuously removing material like cutting. The harder the material, the longer the machining time.

Although EDM can achieve precision at the micrometer level, its machining accuracy is still affected by electrode wear, voltage pulse irregularities during discharge, machining liquid conditions, etc. Especially in the machining of complex shapes and free surfaces.

3. Surface roughness

The high temperature of the plasma generated by EDM may cause fine pits and cracks on the workpiece surface, resulting in higher surface roughness which requires subsequent processing.

4. Easy to produce surface residues

Impurities generated by corrosion of the working fluid and plasma may remain on the workpiece surface, affecting surface quality.

5. Large electrode wear

After repeated discharge, the material of the electrode will gradually fall off, and the service life of the electrode depends on the quality of the electrode and discharge conditions.

6. High environmental requirements

EDM must be carried out in a sterile closed environment, and the machining environment is highly sensitive to impurities.

7. Relatively high cost

EDM machine is expensive and maintenance costs are high. Electrode wear and the use of discharge media will also increase machining costs. Therefore, the single machining cost is higher than CNC. Not suitable for small batch or low cost applications.

8. Small machining range

It is difficult to complete large-scale machining in one operation and is only suitable for precision mold manufacture or machining of a small number of workpieces.

Although EDM is non-contact machining, the electrode will still gradually wear away due to heat and electrochemical effects during discharge. Electrode wear requires regular replacement or repair, increasing machining costs and maintenance work.

The surface quality of electric discharge machining is affected by many factors such as discharge parameters, electrode material, workpiece material, etc. These factors may cause non-uniform erosion marks, micro-cracks or pores on the machined surface.

11. Requirement for operating skills

EDM requires operators to have certain professional skills and experience to correctly set machining parameters and control the machining process, which imposes high demands on operators.

12. Need for post-processing

Due to possible roughness and micro defects on the EDM machined surface, subsequent processes such as grinding, polishing, etc. may be needed to achieve the required surface quality.

13. Material limitation

EDM requires the workpiece to be machined to be electrically conductive. Therefore, it cannot machine non-conductive materials such as ceramics and glass. Some soft materials may not be suitable for EDM. This limits the application of EDM in some specific fields.

EDM consumes a lot of electricity without recycling. With more and more companies paying attention to carbon footprint, some low-energy machining methods may be preferred. And the waste liquid needs to be treated to meet environmental requirements.

EDM technology is mainly suitable for processing difficult-to-machine materials, complex shapes, precision parts, thin-walled parts and brittle materials. It is a non-contact process that can overcome the limitations of conventional mechanical machining. EDM (electrical discharge machining) is mainly suitable for the following situations:

During EDM, there is no contact, so thin-walled parts will not be damaged by deformation.

EDM process can machine some brittle materials without damaging the workpiece, a typical application we encounter in actual production is drilling holes on neodymium iron boron magnets, which can’t be achieved by conventional methods. It can be realized through EDM drilling.

When parts require extremely high precision and surface smoothness, EDM is an ideal choice. Since it removes material through discharge, it can avoid errors caused by vibrations and heat in mechanical machining. EDM can provide machining accuracy at the micrometer level.

For complex shapes that are difficult to machine with conventional cutting tools, such as deep holes, microholes, slots and free surfaces, EDM provides solutions. It is not limited by tool shapes as the discharge area can be of any shape.

When facing materials with high hardness, high strength or difficult to machine through conventional CNC cutting methods, EDM is an ideal choice. Typical examples are cemented carbides, tungsten carbide, titanium alloys, high-temperature alloys and 316L stainless steels machining.

EDM can also be used for repairing and modifying existing parts, especially when the original tools or drawings are unavailable, it can precisely replicate the shape of parts through EDM.

In mold manufacturing and maintenance, when the cutting edge of the tool becomes worn or needs shape modification, EDM can be used for repair and remachining to extend the service life of the tool.

For small parts, EDM has advantages. It can achieve micrometer-level or even sub-micrometer-level detailed machining suitable for various microelectronic, optical and medical device industries.

The machining speed of EDM is relatively slower than traditional mechanical machining, especially in machining large-sized parts or situations where a large amount of material needs to be removed. This may affect production efficiency and cost-effectiveness.

EDM machining involves multiple parameters such as pulse width, pulse interval, discharge voltage, current and dielectric medium pressure. The interaction between these parameters is complex and requires precise control to achieve optimal machining results. Improper parameter selection may lead to decreased machining quality or excessive electrode wear, affecting the final product quality.

EDM equipment can usually only machine small parts, with limited capacity for large workpieces.

During the EDM process, continuous discharge occurs between the electrode and workpiece, gradually wearing and consuming the electrode material. This not only increases machining costs but may also affect machining accuracy and stability, causing instability to the process.

The electrode is a key component in EDM machining. Different electrode materials will affect the EDM machining process. Proper selection of electrode material is needed.

Although EDM can achieve high machining accuracy, the machining process is still affected by various factors such as discharge parameters, electrode wear, workpiece material properties, etc. These factors may cause fluctuations in machining accuracy. Therefore, it is necessary to regularly detect and adjust electrode wear to maintain machining accuracy. As a result, how to select suitable electrode materials, optimize electrode structure and machining parameters to reduce electrode wear and control accuracy is an important challenge facing EDM technology.

The machined surface after EDM may have fine pits and non-uniformity, which requires subsequent polishing or grinding processes to improve. The causes may be inevitable pores in the electrode material that affect the quality of the workpiece surface during machining. This unpreventable factor is also a challenge.

The cooling and flushing capacity of the dielectric liquid will affect the effect of EDM machining. Dielectric liquid with good performance is needed.

Although EDM has advantages in some specific applications, its equipment, electrode and maintenance costs are relatively high. This makes it difficult to popularize EDM in some cost-sensitive applications. Therefore, how to reduce the cost of EDM technology and improve its cost-effectiveness is an important challenge in promoting this technology.

EDM requires fine adjustment of parameters according to different materials, making it difficult to achieve full automatic monitoring and optimization of process quality control. Different workpieces still need multiple simulation debugging to complete programming automation.

Although EDM is a non-contact machining method, the heat generated during discharge can still cause local microstructural changes in the workpiece, affecting material performance.

In EDM machining, it is necessary to balance the material removal rate and electrode consumption rate. Excessive material removal rate may lead to rapid electrode wear, while insufficient removal rate will affect machining efficiency.

EDM machining processes may produce hazardous gases and dust, requiring proper ventilation and filtration measures to protect operator health and work environment.

EDM processes require large amounts of electricity. With increased environmental awareness, if energy consumption cannot be reduced, it may be replaced by other machining methods.

The complexity of EDM processes means experienced technical personnel are needed for operation, which may lead to shortage of talent issues.

The discharge current is the amount of current flowing through the discharge gap. The magnitude of current directly affects the energy and material removal efficiency of the discharge. A higher current can increase the material removal rate but also increases electrode wear, risk of heat affected zone, and surface roughness of the workpiece.

The discharge voltage refers to the voltage applied between the electrode and workpiece. It determines the intensity and energy of discharge, thus affecting the stability and efficiency of machining. Too low voltage may lead to unstable machining, while too high voltage may cause excessive heat affect and electrode wear.

The pulse interval is the time interval between two consecutive pulses. It affects the continuity and stability of discharge. A shorter pulse interval can increase the material removal rate but may lead to rapid electrode wear; a longer pulse interval helps reduce electrode wear but will lower machining efficiency.

The pulse width is the time length of the discharge pulse. It directly affects the material removal rate and electrode wear. A shorter pulse width is conducive to improving machining accuracy and surface quality but will reduce the material removal rate; while a longer pulse width will increase the material removal rate but may sacrifice surface quality and accuracy.

The working liquid in EDM machining serves the functions of cooling, flushing and providing electrical conductivity. Appropriate dielectric pressure helps cool, remove machining products and maintain the stability of the discharge gap. Too low pressure may cause unstable machining, while too high pressure may affect the uniformity of discharge. In addition, different working liquids have different insulation and cooling performance, such as kerosene having better insulation and deionized water having better cooling effect.

The electrode material directly affects the material removal rate and electrode wear. The machining process should be selected according to the electrode material to reduce electrode wear, improve machining efficiency and quality. The suitable electrode material should also be selected according to the workpiece structure. Common electrode materials include graphite, phosphor bronze and tungsten.

The conductivity, hardness and thermal properties of the workpiece material have a significant impact on EDM machining. Harder materials are more difficult to machine, but the process can be optimized through suitable parameter selection and electrode material.

The machining strategy includes process planning of machining path, geometric design of electrode, and arrangement of multi-stage machining. A reasonable strategy can improve machining efficiency, reduce electrode wear, and ensure machining quality.

The distance between electrode and workpiece (also known as discharge gap) is a key factor affecting discharge stability and machining accuracy. Too small a gap may cause unstable discharge, while too large a gap may lower machining efficiency. Therefore, this parameter needs to be adjusted based on specific conditions to ensure stable discharge and efficient machining.

Electrodes of different shapes and sizes are suitable for different machining requirements and affect machining accuracy and precision.

The electrode will wear away due to repeated discharging, leading to a decrease in machining accuracy. The reasons for rapid electrode wear may include improper selection of electrode material, excessive discharge energy, unstable dielectric conditions or excessively long machining time. Problems such as peeling and cracking may also occur on the electrode surface.

The edges and corners of the workpiece are prone to excessive discharge, resulting in reduced machining quality. The trajectory and discharge distribution of the electrode need to be controlled.

The machined surface of the workpiece after EDM may have cracks, pores, unevenness, excess roughness, etc. These problems may be caused by inappropriate dielectric composition, unreasonable setting of discharge parameters, unsuitable electrode material selection or improper temperature control during the machining process.

Deformation of the workpiece during machining. This may be due to factors such as heat stress or inferior material quality.

Although EDM can achieve high-precision machining, in actual operation, due to electrode wear, machine tool deformation, equipment accuracy, inaccurate positioning and other factors, the actual production can not achieve the ideal tolerance as expected. The selection of discharge parameters and machining strategies will also affect the machining accuracy.

In high-speed wire EDM, the electrode wire is easy to break due to friction, deviation and other reasons, affecting machining continuity.

The electrode material may have peeling phenomena, affecting the machining effect. This is usually due to mismatch of thermal expansion coefficients.

Discharge may occur open circuit, short circuit, arcing discharge and other abnormal states, affecting machining quality and efficiency. Fine control of discharge parameters is required.

EDM equipment can usually only machine small parts, with limited capacity for large workpieces.

EDM able to machine various materials, but in practical application, factors such as the material’s conductivity, hardness, thermal expansion coefficient need to be considered for their influence on the machining effect. In addition, different materials may require different electrode materials, discharge parameters and machining strategies to achieve optimal machining results. These are the materials that can be processed by EDM based on our 10+ years of experience:

Iron: The most common metal, widely used for various metal parts.

Aluminum: Light weight, good electrical conductivity, with wide application in aerospace, automotive and other fields.

Cemented carbides: Commonly used for manufacturing cutting tools such as drills, milling cutters.

Stainless steel: Has excellent corrosion resistance and is widely used in chemical, food processing industries.

Titanium alloys: wear resistant, high strength, nice corrosion resistance, high biocompatibility

Copper alloys: nice electrical and thermal conductivity, used for electrical contacts, heat sinks, etc.

Magnesium alloys: Light weight property makes it applicable in automotive, electronics and other fields.

High-strength steels and alloy steels: Used for manufacturing high-strength structural components and mechanical parts.

Tungsten steel: Tungsten has high hardness and wear resistance. Used for machining high strength and precision parts.

Difficult-to-machine materials

Heat-resistant alloys: Such as nickel-based superalloys, tungsten steel, cobalt-based alloys, hastelloy alloys, haynes alloys and inconel alloys with excellent corrosion and high temperature properties. Used for parts working in high temperature environments.

Magnetic materials: Such as neodymium-iron-boron, ferrites permanent magnetic materials, used for manufacturing high-performance permanent magnets.

Graphite: Commonly used as electrode material. Has good electrical conductivity and self-lubricating properties and used in some special cases.

Copper: Includes brass, copper and bronze, with good electrical and thermal conductivity. Brass is an excellent choice for sinker EDM electrodes, but due to its flexibility, it cannot be used to produce electrodes with fine grooves or holes. Commonly used for manufacturing conductive parts and heat conduction components.

Such as silicon carbide, silicon nitride. They have excellent hardness and wear resistance. With wear resistance, high temperature resistance and suitable for specific working environments.

Composed of two or more materials to produce unique properties. EDM processing can be performed according to the specific characteristics of the composite material.

When machining with the EDM process, there are different electrical discharge machining tolerances in terms of linear dimensions, geometric dimensions, and surface roughness.

Electrical discharge machining tolerances typically ±0.005mm to ±0.025mm (±0.0002 inches to ±0.001 inches), depending on workpiece geometry and material properties.

electrical discharge machining tolerances usually up to ±0.05mm to ±0.1mm (±0.002 inches to ±0.004 inches).

Usually Ra 0.2μm to Ra 1.6μm (8μin to 64μin), the specific actual accuracy depends on the processing parameters, electrode material selection and workpiece material characteristics. Surface finish also depends on the speed of the machining process; the slower speed, the better surface finish. However, slower movement also increases costs.

CNC (computer numerical control) and EDM (electrical discharge machining) each play important roles in manufacturing and machining, but there are obvious differences between them. Here are some professional explanations of the differences between CNC and EDM:

CNC machining uses mechanical cutting of workpieces on CNC machine tools by tool movement to remove material and process the required parts. It is applicable to materials that can withstand cutting forces. CNC machining relies on direct contact between the tool and workpiece.

EDM machining uses pulse discharge to generate high temperature between the workpiece and electrode, locally melting, evaporating or burning the material for removal. EDM machining does not rely on mechanical cutting force, but removes material through thermal effect of electric spark.

CNC process can mill and trun hard and soft materials such as steel, aluminum, copper, plastics, wood, composite materials.

EDM is particularly suitable for machining hard materials, wear-resistant alloys, high-temperature alloys and other materials that are difficult to machine by conventional cutting methods.

CNC has fast speed, high accuracy, better surface finish but is limited by tool material and shape for complex shapes or microstructures. It also involves mechanical cutting force which may cause workpiece deformation or damage.

EDM can machine complex shapes and fine details without tool wear, and no mechanical stress in the process. It is suitable for precision, complex shapes and fragile or thin-walled workpieces. But the speed is relatively slow and the surface may need subsequent processing to improve finish.

CNC has slight disadvantages in machining accuracy and surface quality but has advantages for larger workpieces.

EDM can achieve higher machining accuracy and better surface quality, especially suitable for complex shapes and internal details.

CNC is widely used in automotive, aerospace, plastic mold manufacturing, metal mold manufacturing, mechanical processing industries, especially suitable for mass production and situations requiring high efficiency.

EDM is commonly used in manufacturing precision plastic molds, medical parts, aerospace components, especially suitable for small batch and single unit production requiring extremely high precision.

CNC equipment is generally more expensive and requires professional programming and operation skills; EDM equipment is also not cheap but operation and maintenance are relatively simpler. Also, as the EDM process involves electric spark discharge, special protective measures are needed to ensure operational safety.

Dielectric fluid plays a vital role in electrical discharge machining (EDM), as it not only acts as an insulator but also is responsible for cooling and flushing the machining area, and helping to remove melted and evaporated material. When selecting an EDM dielectric fluid, factors such as the type of workpiece material, machining parameters, machine performance, environmental regulations and cost must be considered. The right dielectric fluid can not only improve the efficiency and quality of EDM machining but also ensure operational safety and environmental protection. Therefore, understanding the characteristics and applicable scenarios of different types of dielectric fluids is critically important for optimizing the EDM machining process. These are the common types of EDM dielectric fluids are:

Mineral oil-based dielectric fluid was one of the earliest types of dielectric liquid used, mainly composed of refined petroleum distillates. It has good insulating properties, thermal stability, and higher flash and fire points, applicable to most EDM applications. However, it has a greater potential environmental impact and may also affect the machining performance of some materials.

Synthetic ester-based dielectric fluid is made from synthetic chemicals and has better cooling performance, lower viscosity, thermal stability, excellent insulating properties and higher flash points, with overall performance superior to mineral oil-based fluids. It has better biodegradability and causes less environmental pollution. However, the cost is generally higher than mineral oil-based dielectric fluid and it may require more stringent use and handling specifications.

Water-based dielectric fluid mainly consists of deionized water and additives. It has excellent cooling performance and can effectively control the temperature during the machining process. It has advantages of being environmentally friendly, easy to handle and recycle. But it may have corrosive effects on some metal materials.

Specialty dielectric fluids are designed to meet specific machining needs and may contain specific additives (such as antifoaming agents, corrosion inhibitors, filtering aids) to improve discharge stability, reduce electrode wear or increase machining speed. These dielectric fluids can be customized according to machining materials and conditions to optimize machining performance and quality.

Multiple components work together to assemble the entire EDM processing system. The design and performance of these components directly affect the performance of the electric discharge machine. When selecting an cnc electrical discharge machine, the performance and matching of these key components need to be fully considered.

The pulse power supply is the core of the EDM system. It is responsible for generating pulse discharges with specific voltage and current to generate sparks between the workpiece and the electrode. The stability and adjustment ability of the pulse power supply directly affect the processing efficiency and quality.

The power supply provides the required electrical energy for EDM, while the control system is responsible for monitoring and controlling the movement of the machine tool, including the feeding and positioning of the electrode, and the discharge parameters of the pulse power supply to ensure the continuity and consistency of the machining process. The control system usually uses CNC technology, which has the characteristics of high precision, high speed and stability, and can realize complex processing procedures and operations.

Amateur systems mainly monitor various parameters during the processing process, such as voltage, current, temperature, etc. Real-time feedback information to adjust processing parameters and identify potential problems in a timely manner.

Dielectric fluid plays a role in cooling, chip removal and insulation in EDM. The working fluid circulation system is responsible for the supply, filtration and circulation of working fluid to ensure the stability and efficiency of the processing process.

The machine tool body provides a stable processing platform, including a workbench, electrode holding device and workpiece holding device. It includes a motion system of coordinate axes to achieve precise positioning and movement. The rigidity and stability of the bed and column are crucial to ensuring machining accuracy

The workbench is the core component that supports and positions the workpiece. It often has precise three-axis movement capabilities to achieve accurate positioning and clamping of workpieces. There is usually a working fluid tank on the workbench to contain the working fluid to ensure cooling and chip removal during EDM.

Electrodes are electrically conductive tools that direct electrical discharge and remove material from the workpiece. The selection of electrode materials and shape design have a significant impact on processing efficiency and processing quality. The preferred electrode material is graphite, followed by copper, and tungsten is the best.

Safety devices include overload protection, short circuit protection and leakage protection to ensure the safety of operators and equipment.

Attractive Plastics is an China injection molder, our main capabilities are mold making, injection molding, CNC machining, sinker EDM, wire EDM, ultrasonic welding. We aren’t electrical discharge machining manufacturers and electrical discharge machining machine manufacturers , but we provide high quality electrical discharge machining services, typically including wire EDM, sinker EDM machining, EDM drilling. Our knowledgeable team of engineers can confirm that your custom injection molding project meets the required specifications. If you have any issues for injection molding, mold making, EDM machining, feel free to contact them, they are at your service 7/24.

Electrical discharge machining, as an efficient, flexible and precise machining method, plays an irreplaceable role in modern manufacturing industry. By different types of EDM technologies (wire-cutting EDM and sinking electrode EDM), engineers and technicians are able to solve challenges that are difficult to overcome by conventional mechanical machining, especially in machining hard materials and complex shapes. We believe EDM will demonstrate its tremendous potential in more fields and bring new opportunities and challenges for the development of manufacturing industry.

What are safety precautions should be observed when operating electrical discharge machining equipment?

Personal protection: Operators should take necessary protective measures such as flame retardant and anti-static work clothes, protective glasses, earplugs or earmuffs.

Environmental safety: Harmful gases and fumes may be produced during the EDM machining process, so it is necessary to ensure good ventilation conditions in the working area.

Follow operating procedures: Strictly follow the operating manual of the device and do not arbitrarily change device settings without sufficient knowledge and experience.

EDM Equipment inspection and maintenance: Regularly check the electrical circuits, dielectric liquid system and filtration system of the electrical discharge machine to ensure they are in good working condition.

Prevention of fire and explosion: Fire extinguishers should be provided near the EDM equipment and operators should understand how to use them. Do not pile up combustible items around the equipment.

Emergency handling: Be familiar with the emergency stop procedures of the equipment and take immediate action in case of malfunctions or unsafe situations.

Professional training: Ensure all operators have received proper EDM operations training to understand the functions and potential risks of the equipment.

Electrical safety: Avoid contact with live components to prevent electric shock and electrical injuries. Ensure all metal parts are properly grounded to prevent static discharge.

Dielectric fluid safety: Avoid contact with the dielectric fluid to prevent skin irritation and slipping. Promptly clean up any spilled dielectric fluid to prevent slip accidents.

Mechanical safety: Stay away from moving parts such as electrodes and workpiece fixtures to prevent being drawn in or struck. Carefully handle workpieces to prevent them from falling or splashing.

Can EDM machine Inconel®?

Of course, any metal that conducts electricity can be machined by EDM. Inconel® is an extremely hard alloy, which is impossible to handle by conventional CNC machining processes. EDM is the best way to machine Inconel®. Of course, because of its high hardness, the acceleration speed will be slower and the efficiency will be lower, but the precision and surface finish can be guaranteed.

Can magnets be processed with EDM?

No problem. Magnets are electrically conductive metal materials, so they can be processed by EDM. Magnets are very brittle and EDM is the most suitable production process, which is efficient and unbreakable. Widely used are wire-cut magnets. NdFeB magnets are very expensive and it is recommended that the scrap of processed magnets should be collected for reuse.

What is micro electrical discharge machining?

Micro Electrical Discharge Machining, or μEDM for short, is a precision manufacturing technology for processing small sizes and complex shapes. It is a branch of traditional electro discharge machining and is specially developed for micro-scale processing needs.

In micro electro discharge machining, tiny electrodes are used to create tiny discharge channels. This processing technology often involves micron or even nanometer tolerances and is suitable for manufacturing micro molding parts, micro molds, microfluidic chips and other micro systems.

What’s the electrical discharge machine price

The price of an electrical discharge machine is influenced by many factors, including the type of machine tool (wire cut EDM or ram EDM), specifications, performance, precision, machinable materials, manufacturer, technical configuration and market supply and demand conditions. In addition, the costs of machine maintenance, consumables and operator training will also increase the total cost of owning an EDM machine. It is recommended to consult reputable electrical discharge machine manufacturers for detailed quotes based on specific requirements and needs.

Small electrical discharge machines are priced around US$10,000. These benchtop machines are mainly used for simple prototyping work with their compact size.

Medium-sized electrical discharge machine generally range from US$30,000 to US$100,000. this type machines have stronger power and more robust construction to machine workpieces with higher dimensional and accuracy demands.

Large cnc electric discharge machine prices start from US$150,000. Employing CNC systems, these precision machining centers enable high productivity batch production. High-end models from major electrical discharge machine manufacturers can exceed US$300,000.